Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

0-120 Meters/Minute Plaster Ceiling Roof Truss Omega Profile Roll

Forming Machine with Embossing Ribs

Furring channel machine is used to plaster board, gypsum board and

other decorative finishes lightweight board made of

non-load-bearing walls and roof of the building style decoration, a

variety of decorative building roof shape, inside and outside the

building wall and ceiling scaffolding base material.Products made

by this machine are suitable to use in hotels, theaters, shopping

malls, factories, office buildings, old building renovation,

interior decoration settings, roof and other places.

Material for this machine is galvanized steel plate, snowflake

plate and cold steel plate,we can according to customer design,

manufacture different specifications of cold-formed.

In Drywall system and drywall partition system, we could provide

roll forming machine as following:

1. Technical Parameter

2. Machine Components

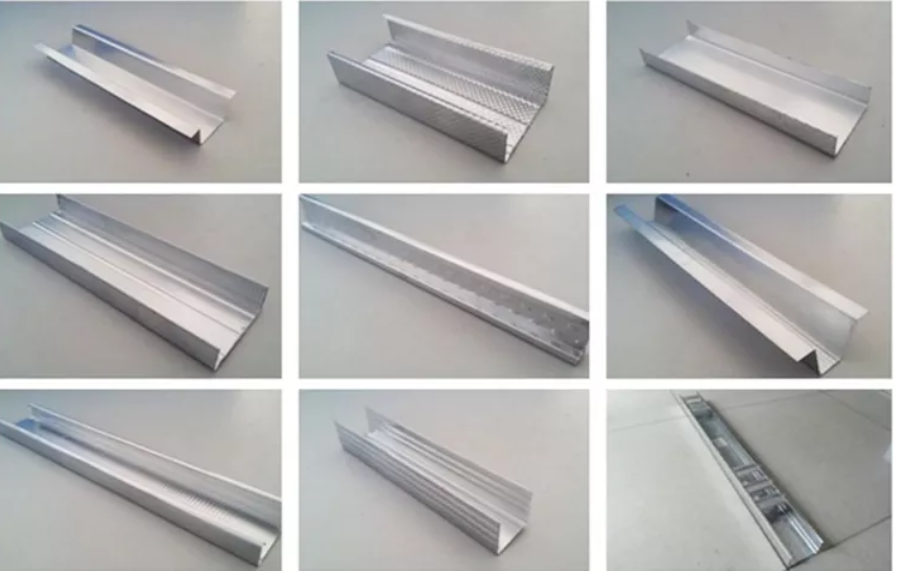

Profile Drawings:

3. Features of the production line

1) Directly input the data on the touchable screen, it is easy

operation.

2) Automatically continually manufactures high quality product with

PLC.

3) Saving time and cost owing to high speed running with hydraulic

system.

4) Professional designing for manufactures roofing & walling

5) Customers decide the profile of products.

4. Steel profile

.

5. Application