Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

Galvanized Steel Profile Roller Shutter Door Guide Rail Roll Forming Machine With PLC Control

Company Information

Sussman Machinery is specialized manufacturer of roll forming

machinery for purlins, stud, decking. racking, roofing, glazed

tile, shutter doors, solar panel, pu sandwich line, ect. We have

more than 10 years production experience and have shipped our

machines to more than 80 countries.OEM is welcome here. Any

requirements just no hesitate to contact with us, we must try our

best to satisfy your needs. Reasonable price and best service will

be provided to you.We are very much glad to work with you.

Door Rail Technical Parameter

1. Steel Sheet Thickness: 0.7-1.2mm (depend on

requirement )

2. Transmission way: single chain

3. Transmission material: 45# steel, high frequency quenching

4. Material of blad: Cr12, quenching treatment

5. Capacity of Decoiler: 3 ton passive decoiler

6. Forming Speed: 8-10m/min

7. Roller Groups: 12 stations

8. Roller Material: Cr40 steel, high

frequency quenching treatment, HRC58-62

9. Material: galvanized steel

10. Principal Axis: 45# high grade steel with

quenching treatment

11. Main Motor Power: 5.5 Kw

12. Hydraulic Power: 4Kw

Door Rail Main Components

| S.N | Equipment name | Quantity |

| 1. | 3T passive un-coiler | 1 set |

| 2. | feeding and leveling device | 1 set |

| 3. | Main roll forming machine 12 stations drived by chain

| 1 set |

| 4. | Hydraulic cutting | 1 set |

| 5. | Control system (including control box) | 1 set |

| 6. | Out tables | 2 sets |

| 7. | Hydraulic punching | 1 unit |

Advantage for Door Rail

1.The design of Roll Forimg Machine is convenient to adjust, for it owns reasonable structure, compact shape, high precision and high efficiency.

2.The manufacturing process of the complete machine is in strict accordance with the mechanical standards, tracking and controlling the manufacture of each part.

3.Professional team for technical research and development, providing users with automatic plate processing equipment of high quality and efficiency.

4.The entire line is controlled with PLC, with touch screen of display and operation and high automation.

Working Flow of Door Rail

Decoiler----Servo Feeding and Leveling---Punching---Roll

forming---Cutting---Run out tables

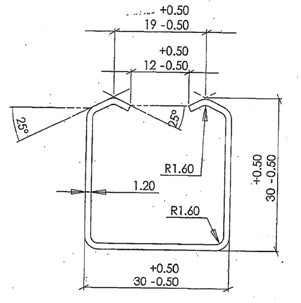

Profiles of Door Rail

Loading Pics

Packaging Details: Naked,Spare Parts Put Into BoxElectric Parts

Packed with Plastic Films

Delivery Detail: Shipped in 60 days after payment

Our Services

Terms of Payment: 30% of the total contract value paid by T/T as

down payment, the rest

70% of the total contract value to be paid by T/T after inspection

by buyer in seller’s factory while before delivery.

Service: we sent technician to your country to fix the machine.

The buyer should bear all the cost including: visa , Roundtrip

ticket and suitable

accommodation, also buyer should pay the salary 100USD/day.

Warranty: 12 months limited warranty

During warranty, parts are free but buyer pay for the shipping fee