Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

0.7-1.2mm Thickness Galvanized Steel Metal Shutter Door Roll Forming Machine With Chain Drive

Rolling shutter doors are produced by rolling shutter machines and are used for parking lot doors and home doors, store front displays and garages, etc. They are very sturdy and a sage to the property. Therefore, roller shutters provide adequate protection and security against theft and fire. These doors are stronger if sufficient steel thickness is used.

In fact, we can supply different kinds of roll forming machines for different shutter doors. If you have your door design, show us your design drawing. A good suggestion can be given out by our enginneer. If you have any idea about your new project, some professional ideas can be gotten from us.

| No. | Item Name | Specification |

| 1 | Feeding width | Customized as customer' drawing |

| Effective width | Customized as customer' drawing | |

| 2 | Thickness of panel | 0.7-1.2 mm coil sheet |

| 3 | Roller station | 12 stations |

| 4 | Shaft Diameter | 60 mm |

| 5 | Productivity | 8-12 m/min |

| 6 | Rollers' material | 45# steel with 0.05mm chrome |

| 7 | Shaft material | 45# steel with 0.05mm chrome |

| 8 | Weight | 3 tons |

| 9 | Size | 4.5*0.5*0.8m |

| 10 | Voltage | 380V 50Hz 3phases |

| 11 | Control | PLC |

| 12 | Decoiler | 3 tons |

| 13 | Motor | 5.5 kw |

| 14 | Driving way | Chain transmission |

| 15 | Cutting system | Hydraulic cutter |

Profile Drawing

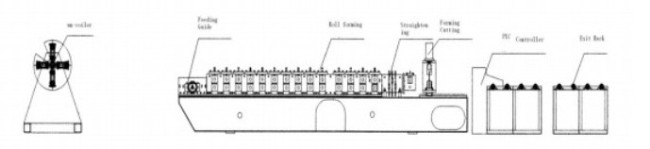

Machine Shows

Application:

Packaging and Delivery

Before loading to the container, we will check the machine first;

Second, make some protection on the machine, Such as, we will

mpaint the coil on the roller and shaft, in case the roller and

shast got corrosion and rusty during long time delivery;

Third, we will make the plastic package on the easy damage parts,

and fix all the parts into container by the steel wire rope, and

ensure the machine will not damage when shaking on sea;

At last, we will take photos for customer when loading to

container.