Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

0.6 - 1.5mm 30KW Deck Floor Cold Roll Forming Machine For Color Steel Tile

1. Technical Parameter

2. Machine Components

| 5 Ton passive decoiler | 1 set |

| Main roll forming machine | 1 set |

| Control box | 1 unit |

| Hydraulic station | 1unit |

| Out table 500mm | 2 units |

3. Details of Each Composition

Cutting:

Control Box: Panasonic Brand

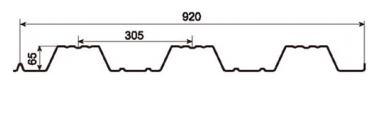

4. Profile

5. Machine Photo

6. Loading Pics

7. Company Introduction

Sussman Machinery (wuxi) Co., Ltd. is a comprehensive enterprise integrating production, sales and services. We are mainly engaged in providing machineries and equipment. Owing to a professional teamwork, we are experienced in manufacturing, import and export, customers' design, installation and test, technical solution and after-sale services. We have shipped out our machines to more than 50 countries, and keep good business relationships with a large amount of worthy customers, contributing to our great business records and reputation.

8. Commissioning of the Machine

The components of the machine are commissioned one after the other. At the end of the commissioning the machine is ready for production and is handed over.

The commissioning comprises:

- Commissioning by Suhang service technicians

- Training at the machine

- The following services are rendered

- Run up of the machine components

- Testing of all functions of the machine components

- Start of a fully automatic molding process

- Execution of machine acceptance

Delivery extent does not comprise of:

- Raw materials, process materials and consumables

- Raw material for test

- Transport and lifting devices

The operators of the plant should be present during the commissioning in order to become familiar with the new machines.

8. Installation of the Machine

The individual components of the machine are installed according to the layout and prepared for the commissioning.

The installation comprises of:

- Installation by Suhang service technicians.

- The following services are included:

- Installation of the machine components.

- Adjustment of the machine components.

- Connection of all motors to the control cabinet.

- Installation of the required safety devices.

Delivery extent does not comprise of:

- Media supply (electrics, etc.)to the machine(control cabinet)

- Raw material,process material

- Raw material for test

- Transport and lifting devices

- Auxiliary staff.

The operators of the plant should be present during the installation in order to become familiar with the new machines.