Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

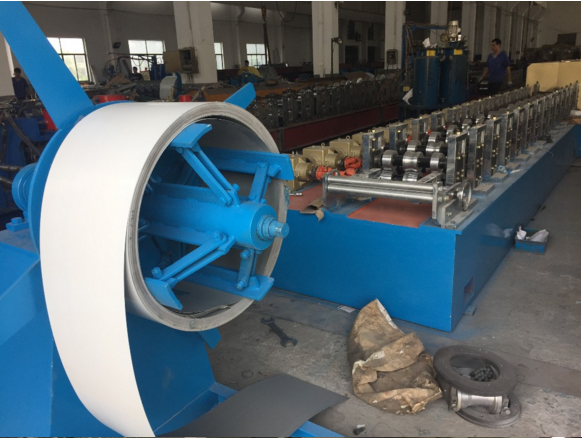

Automatic 77mm PU Foam Rolling Shutter Slat Cold Roll Former Machine With Material Thickness 0.4mm - 0.6mm

Features

1. PLC computer control

2. Hydraulic system, long operating

3. Easy operation

4. Beautiful appearance and best after-sales service

Technical parameter

1. Steel Sheet Thickness: 0.4-0.6mm (depend on requirement )

2. Covered Width: 85mm ( depend on prfoile )

3. Coil Width: 140mm ( depend on prfoile )

4. Decoiler: Manual Decoiler

5. Capacity of Decoiler: 3 Ton

6. Forming Speed: 8-15m/min

7. Roller Groups: about 42 steps main roller

8. Roller Material: GCr15 high grade steel with finish machining treatment, by high frequency quenched HRC58-62

9. Roller Diameter: 110mm

10. Principal Axis: 45# high grade steel with quenching treatment

11. Main Motor Power: 11 Kw

12. Transmission way: gear box

Rolling PU Shutter Profile Drawing

Main Components

| Manual Decoiler | 1 set |

| Guide Feeding device | 1 set |

| main forming machine | 1 set |

| Foaming machine (just foamed one owned) | 1 set |

| Straighten device | 1 set |

| Punching device | 1 set |

| flying saw cutting machine | 1 set |

| Our table | 2 units |

| PLC control system | 1 set |

Rolling Shutter Door Forming Machine Pictures

Advantage for our PU roller shutter

1. We are a professional factory manufacturing, best production capability, best quality control, best service.

2. Inspected by the Inspection Institution of Bureau Veritas Certification.

3. 100% QC inspection Before Shippment.

4.Competitive Price.

5.We can provide oversea after sales services.Our engineers have been to Chile, Nicaragua, Indonesia, Russia, Saudi Arabia, Singapore, and other countries for installation and training. Considering the time difference, we can also offer online instant video to help customer to solve problems.

FAQ

Q: Do you have after sales support?

A: Yes, we are happy to give advice and we also have skilled

technicians available, We need your machines running in order to

keep your business running.

Q: Once we've bought a machine from you, are you able to supply us with material?

A: We can assist you in finding the appropriate materials to suit your machine

Q: What size decoiler can you supply us with?

A: From 3-ton decoiler to a 25-ton motorised hydraulic decoiler

Q: Do you have a warranty on your machines?

A: One year warranty

Q: Do you have instruction manuals?

A: We provide you with instruction manuals, electricity layouts,

civil requirements, and machine drawings

Q: Once a machine arrives at our factory what happens then?

A: We will send you a technician or engineer that will commission

and install your machine, with training for your staff if required

at a separate fee.

Q: My current machine rollers need to be replaced. Would you be

able to assist me?

A: Yes. Send us your profile and specifications then we will

manufacture the rollers for you

Q: What is your delivery time?

A: Depending on the type of machine, duration of 30 days to 90 days

from date of order.

Q: Do we receive any updates while machine is in the manufacturing

process?

A: Yes.Regular updates on progress will be sent to you.

Best Regards

Amber Chen

Skype:cqamber

Mobile&Whatsapp:+8618112481091

Web: www.rollformingmachine.info