Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

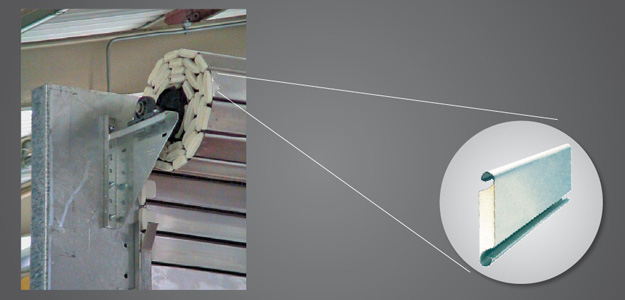

Customize Insulated PU Roller Shutter Door Roll Forming Machine

With Chain Transmission

Technical Parameter

Material type aluminum coil plate and colorful galvanize steel

Material thickness: 0.3- 0.6mm. coil width 140mm

Material yield strength: ≤G200Mpa

Main specification

a. Decoiler

Manual un-coiling Capacity: ≤3 T

b. Main datas of forming machine

Forming stands: about 46 stands

Roller material GCr15: model steel, HRC50-54

Axial diameter: Φ40mm

Main axial material: No 45 steel HRB260-280

Driving part is gear box transmission

Frequency conversion decelerating Delta

PLC control: fix length control ±1mm (Delta)

Main components: CHINT, DELIXI

The precision of roller: less than ±0.5mm

Main roll forming machine motor: 380V, 50HZ, 11kw (or according to your requirements)

Machine basement material: H beam

Foaming machine: 1 set (China top brand)

Pneumatic flying punching machine 1 set

Material of cut: Cr12Mov Quench: HRC58-62

Automatic punching device 1 set

Finished products table: 1 set

Working speed: 8-15m/min

dimensions of main forming machine

24000mm× 600mm × 900mm

Machine weight: about 7T

Main Components

1 | Decoiler | 1 set |

2 | Guide Feeding device | 1 set |

3 | main forming machine | 1 set |

4 | Foaming machine (just foamed one owned) | 1 set |

5 | Straighten device | 1 set |

6 | flying saw cutting machine | 1 set |

7 | finished products table | 1 set |

8 | PLC control system | 1 set |

9 | Spare Parts And Tools | 1 set |

Working Flow of Roll Forming Machine

Decoiler—feedingdevice—mainforming—PUinjection---straightendevice—punching—FlysawCutting ---run out table

Profile of product

Photo Gallery

Our Customer Visiting

Our advantages

1: Factory direct supply price.

2: We have exported for more than 10 years.

3: Our customer are from about 34 countries.

4: We have the professional research team. We can make the machine

according to your requirement.

5: High-end and high-grade design

6: Free technical support and Freeaccessoies supply.