Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

38*12mm Galvanized Steel Small Main Channel Roll Forming Machine for Ceiling and Roofing framing

Technical parameter

1. Steel Sheet Thickness: 0.4-0.8mm (depend on requirement )

2. Hydraulic power: 4Kw

3. Transmission way: chain

4. Chain: 1 inch single chain

5. Capacity of Decoiler: 3 Ton passive decoiler

6. Forming Speed: 10-15m/min

7. Roller Groups: about 13 stations

8. Roller Material: 45# high grade steel with finish machining treatment, by high frequency quenched HRC58-62

9. Roller Diameter: 100mm

10. Principal Axis: 45# high grade steel with quenching treatment

11. Main Motor Power: 5.5 Kw

Applications

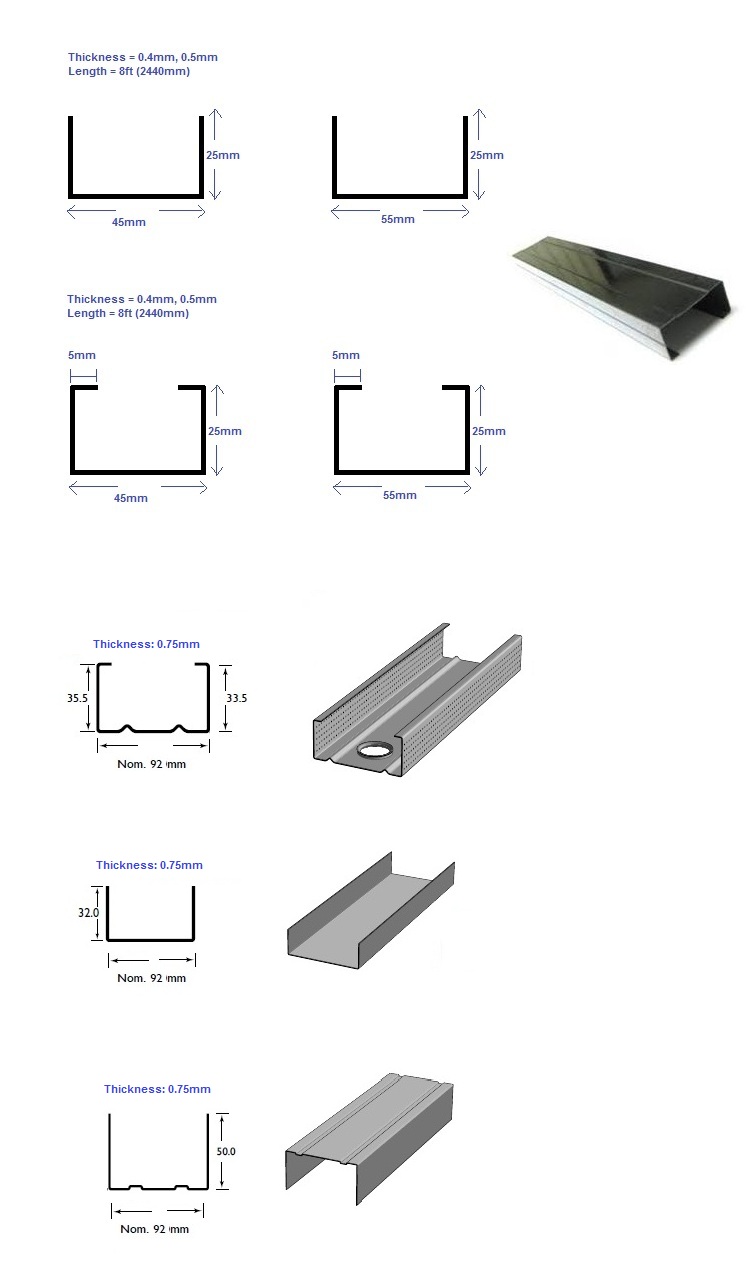

Metal stud and track, steel stud and track, c stud, u runner, u track, furring channel, roof ceiling batten, roof truss, c truss, light weight steel truss...

Main Channel Working Flow

De-coiler—→feedingwithguide—→main roll forming machine—→cutting—→ run out table

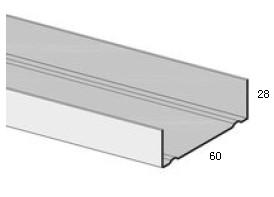

Profile Drawing OF Main Channel Roll Forming Machine

Main Components

Main Components

| Machine list | 3 ton passive de-coiler | 1 set |

| Feeding with guide | 1 set | |

| Main roll forming machine | 1 set | |

| PLC Control box | 1 unit | |

| Hydraulic station | 1 unit | |

| Stop cutting device | 1 unit | |

| Safety cover | 1 unit | |

| Out table | 2 units |

Advantage for Main Channel Machine

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

Main Channel Forming Machine Pictures

Commissioning of the machine

The components of the machine are commissioned one after the other. At the end of the commissioning the machine is ready for production and is handed over.

The commissioning comprises:

- Commissioning by Sussman service technicians

- Training at the machine

- The following services are rendered

- Run up of the machine components

- Testing of all functions of the machine components

- Start of a fully automatic molding process

- Execution of machine acceptance

Delivery extent does not comprise of:

- Raw materials, process materials and consumables

- Raw material for test blocks

- Transport and lifting devices

The operators of the plant should be present during the commissioning in order to become familiar with the new machines.