Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

Two Wave 2mm - 4mm Thickness Guardrail Roll Forming Machine Max Speed 5 - 20m/min

Guardrail Roll Technical Parameter

| 1 | Model No. | Two waves highway roll forming machine |

| 2 | Coil thickness | 2-4mm |

| 3 | Coli material | Steel or other |

| 4 | The bearing capacity of manual decoiler | 5 tons |

| 5 | Shaft material | 45#steel |

| 6 | Shaft diameter | 120mm |

| 7 | numbers of forming steps | 13 stations |

| 8 | transmission | Differential gearbox transmission |

| 9 | Forming speed | 10-15m/min |

| 10 | main motor power | 22kw |

| 11 | voltage | 380V50HZ Three-phase or you need |

| 12 | dimension | 20.5*1.2*1.5m |

| 13 | cutting | Hydraulic cutting |

| 14 | blade material | Cr12 steel with quenched treated 60-62°c |

| 15 | control system | PLC(Delta) |

| 16 | Tolerance | ±1.5mm |

Guardrail Roll Main Components

| S.N | Equipment name | Quantity |

| 1. | 5 ton manual decoiler | 1 set |

| 2. | Feeding and leveling device | 1 set |

| 5. | Main roll forming machine 15 stations drived by gear box | 1 set |

| 6. | Hydraulic station | 1 set |

| 7. | Control system (including control box) | 1 set |

| 8. | Out tables | 2 sets |

| 9. | Punching Device | 2 sets |

Advantage for Guardrail Roll

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

Working Flow of Guardrail Roll

Decoiling—Feeding (take the sheet to the first

station)—leveling----Punching of the sheet ---- hydraulic cut to

length—— roll forming----outtable

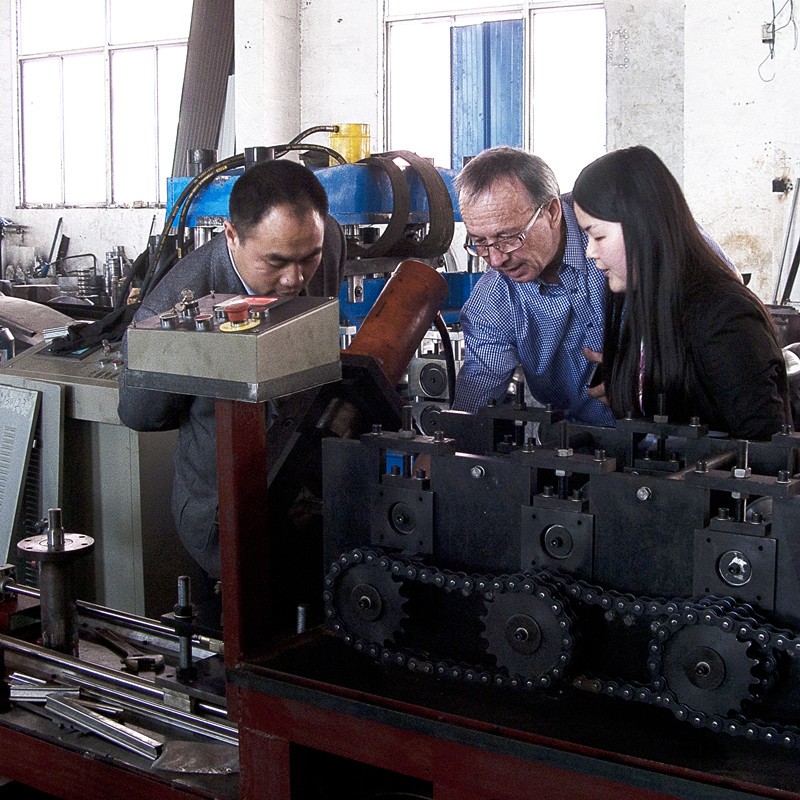

Customes Visiting

Loading Pics

Packaging Details:

1.machine is covered by piastic film

2.PLC control box ,spare parts and other small parts are packed by

wooden carton box.

Delivery Detail: 75days after receipt of the advance deposit.

Terms of payment

30% of the contract amount as down payment after signed the contract; the balance is to be paid by T/T before shipment. Installation charge is to be paid before installation by T/T.

Cost of installation

The buyer should pay the installation charges (USD 100 one man one day). to the seller’s appointed account by T/T before the seller’s technicians go to the buyer’s factory. The buyer pays the seller’s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

Product warranty

12 month, we will provide the technical support for the whole life of the equipment.