Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

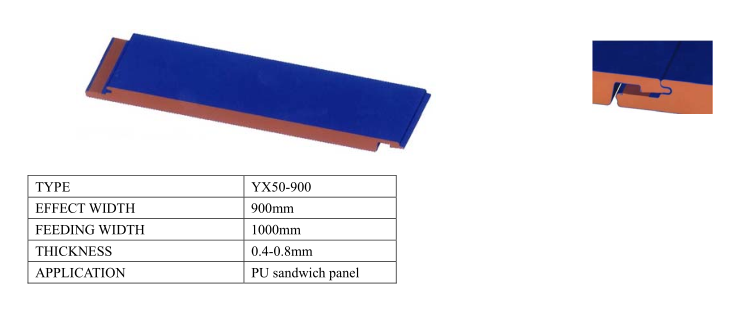

24m Double Belt Cooling System Polyurethame PU Sandwich Panel Production Line 2 PU Foaming Machine

PU Sandwich Panel Technical Parameter

1.1 Uncoiler

a) motor power: 3Kw

b) hydraulic power: 2.2Kw

c) raw material: color steel sheet, aluminum sheet

d) innder diameter of coil: 500mm- 600mm

d) outer diameter of coil: 1200mm

e) coil weight: 10T

f) sheet thickness: 0.4-0.8mm

g) sheet width: 1250mm

1.2 Coil Car

a) hydraulic cylinder lift stroke: up panel 0.5m, down panel 0.5m

b) coil car stroke: 2.5m

c) pressure of hydraulic system: 6.3Mpa

1.3 Two sets of steel sheet transverse cutting machines

a) hydraulic

b) cut steel sheet according to certain length

c) two sets of PVC film covering device wich applies the PVC film onto the steel sheet

1.4 Roll Forming Machine

a) Motow power: up panel 4Kw, down panel 7.5Kw

b) roll forming speed: 1.5-12m/min

c) roller material: 40Cr, surface chrome coated, thickness 0.05mm

d) The way of width adjust: straight track, silk pole, reducer motor adjustable

e) width adjustable range: 600-1250mm

f) sheet thickness: 0.4-0.8mm

1.5 Pre-heating Room

a) temperature sensor: hot couple

b) temperature adjustment: automatic control by temperature control equipment

c) hot air motor: 18.5Kw

d) hot air heater: 200Kw

e) heat type: heated by electricity and air circulate

1.6 Double belt machine

a) effective working length: 24m

b) length & width of double belt: 1400mm x 267mm

c) double belt material: alloy steel

1.7 Band Saw Cutting Machine

a) outline dimension of band saw cutting machine: 5500mmx5000mmx 3000mm

b) run speed of band saw: 1000-1500rpm

c) rotate diameter of band saw: 550mm

d) cutting speed of band saw: 50m/min-1000m/min

e) width of band saw: 30mm

PU Sandwich Panel Main Components

No. | Machine Name |

|

1. | Un-coiler 10 TONS | 2 Sets |

2. | Steel sheet transverse cutting machine, steel sheet surface PVC film covering device | 2 Sets |

3. | Roll forming machine for wall and roof panel | 4 sets |

4. | Panel pre-heat equipment | 1 set |

5. | PU/PIR 2 component Liquid mixing and injecting section for foaming with high pressure (with Singapore brand) | 1 set |

6. | 24m double belt machine include Hydraulic pressure control system with 4 sets side nylon seal blocks to make different thickness of wall panel and roof panel | 1 set |

7. | Heating and heat insulation system | 1 set |

8. | Automatic Panel Bandsaw Cutting Machine | 1 set |

9. | Automatic Vacuum stacking machine and wrapping machine | 2 sets |

10. | Cooling conveyer | 1 set |

11. | Cowper stove 0.5 ton | 1 set |

12. | Air compressor and tank 2 m3 | 1 set |

13. | PU Foaming machines (Singapore Brand) | 1 set |

Advantage for PU Sandwich Panel

1) Excellent quality

2) Reasonable Price

3) Good after Service/Lifetime Service

4) With 15 years professional manufactural experience

5) Customerized,CE marked

6) Technican overseas installing and training.

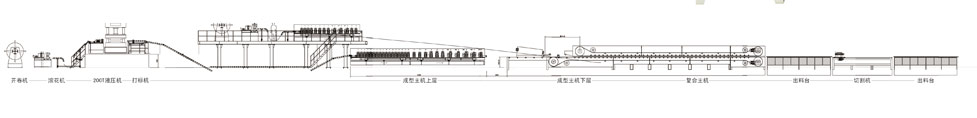

Working Flow of PU Sandwich Panel

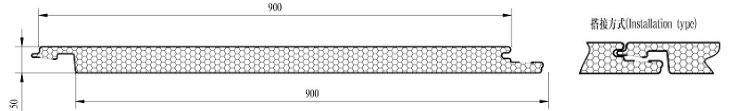

Profiles of PU Sandwich Panel

Loading Pic

Payment Terms

The payment shall be made by L/C or T/T(30% down payment and the

balance for 70% shall be paid before container loading at the

seller`s factory when the buyer check the machine

Delivery Time

90-110 days after deposit