Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

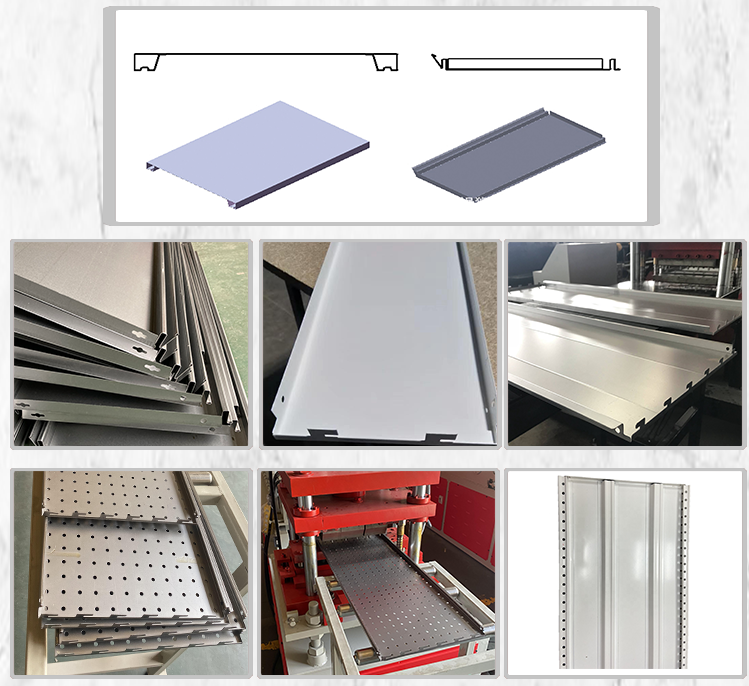

Shelf Box Roll Forming Machine Width Adjustable from Cold Steel Plate 200-600mm with punching Perforation

Warehouse shelf upright system roll forming machine is widely used

to produce upright post, shelf panel, back panel/ board, box beam

and step beam machine, beam welding machine.

The machine can do thickness is from 0.7-1.2mm with raw material

Cold-rolled Steel, Galvanized Coil, Carbon steel.

The shelf box machine is together with the top hat machine to make

the shelf box for the supermarket shelf. Sussman Shelf box machine

is included the de-coiler, the hydraulic punching device, the main

roll forming machine, and the hydraulic cutting device. The shelf

back panel machine can make width from 100-600mm, also can do

200-900mm. It is the good choice for the supermarket shelf

business.

Our produced profile meet ISO, CE, UL standards, and our machine is

applied to Warehouse supermarket ,industry or home. We have

experience of exporting our pallet racking system roll forming

machine to Mexico, Bangladesh, Costa Rica, Russia,Dominica, etc.

The technique data

1. Materials to form: According to the customers’ requirement width, thickness 0.7-1.2mm, length is variable from 0-10000mm

2. Forming steps: About 18 steps

3. Material of rollers:GCr15 steel, precision-machined, high frequency quenching HRC58-62, diameter of rollers: >¢150

4. Material of main shaft : 45# high quality steel (diameter>¢50)

5. Chains’ material: 45# steel, high frequency quenching, circular pitch: 38.1; number of teeth: 13

6. Cutting: Hydraulic cutting; quenching HRC58-62

7. Electronic control: PLC control

8. Dimension of machine: 12000mmX2000mmX900mm

10. Drive system: Chain drive, 7.5KW main motor power, working speed: 3-15m/min;

11. Welding structure: material of fixed beam and walking beam: hot-rolled steel, the base and rack are be gantry planer processing after welded, work platform is not allowed stress deformation; main machine table-board’s plainness <2mm/1000mm

12. Parts: Slide: imported from Japan; bearing: Zhonghang Brand of Harbin

13. Punching: Punching the holes at the press machine before forming the shapes

14. Bending: Bending after the hydraulic cutting

Machine List:

Parts of machine

Working flow

De-coiler—→Level device —→ Hydraulic punching notch—→Main roll forming machine—→Hydraulic cutting—→Bending—→ Run out table

TRANSPORTATION

All goods will be shipped to your country, containers number will be decided with how many machines would you choose