Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

1500m/h New Developed Light Steel Roll Forming Machine with Framing

Software with 7.5KW

Main Characteristics

1. 17 inch color industrial grade computer can choose keyboard,

mouse or touch screen operation. Switching manual or automatic

function at will.

2. With different languages to choose in operation interface, it’s

easy to handle output data in design software can be copy by USB or

teletransmission by Internet.

3. Read design data directly while in production, without manual

intervention.

4. Real-time monitoring whole production process by graphics, which

can show which work piece is working, the length, pcs and material

condition etc.

Main Technical

1. The wall, floor and roof structure is produced automatically, saving design time.

2. Automatic 3D molding, insure 100% accuracy.

3. With analysis project function, the software can calculate bearing capacity.

4. Create frame work 3D map and 3D decoration view.

5. The whole building frame can be resolve to independent unit drawing.

6. Calculate the bill of material, including the needed steel, plates, thermal insulation material,doors and windows, screws and other matching material.

7. Create the processed data including the marked work piece, docking with the equipment.

8. Software maintenance and training fee.

9. Maintenance and supporting fee is USD 2200.00/Year. It’s for software update and optional.

Specification

| Size | 89*41mm or 140*38mm |

| Thickness | 0.6-1.2mm(G300-G550Galvanzied coils and Aluzinc ) |

| Feeding width | 182mm |

| Standard Producing speed | 300-700m/h |

| Max producing speed | 1500m/h |

| Main motor | 5.5kw Servo motor |

| Power supplier | 380V 50Hz 3phases according to your request |

| Hydraulic station | 7.5kw Siemens Motor |

| Hydraulic tank capacity | 100L |

| Hydraulic cooling | Fan cooling |

| Hydraulic pressure | Manually set |

| Host cordless remote control | Standard |

| Frame and punching dies | Screw hole, chamfer, 15mm web hole, flange cut, 35mm pipe hole, suspension, cutting, |

| Product accuracy+- | 0.5mm |

| CNC inkjet-printer | Video Jet |

| Size | 4700*950*1200mm |

| Weight | 5000kg |

| Color | according to your request |

| De-colier | bearing 2 tonne, automatical decoiler |

Technological process

Decoiler—feedingwithguide——punching—Rollforming—Cutting—Products collecting

Profile

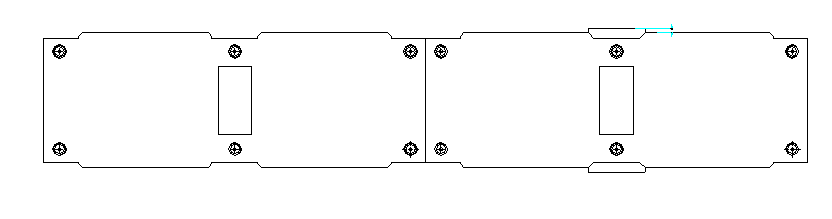

Punching layout

Picture drawing