Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

220mmWidth Profile Width Roll Forming Machinery For Door Frame 2mm Thickness Galvanized Steel

Technical Parameter

| Technical parameters: | |||||||

| 1 | Name of commodity & specification | XN-slat machine | |||||

| 2 | Main motor power | 3kw, 3 phase | |||||

| 3 | Hydraulic motor power | 3kw | |||||

| 4 | Hydraulic Pressure | 10-12MPa | |||||

| 5 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) | |||||

| 6 | Control System | PLC Delta Inverter | |||||

| 7 | Main Frame | 300mm H-Beam | |||||

| 8 | Backboard Thickness | 14mm | |||||

| 9 | Chain Size | 20mm | |||||

| 10 | Feeding Material | color steel coils | |||||

| 11 | Feeding Thickness | 0.3-1.2mm | |||||

| 12 | Productivity | 8-12m/min | |||||

| 13 | Roll Station | 11 | |||||

| 14 | Roller Diameter | 70mm | |||||

| 15 | Roller material | 45# steel | |||||

| 16 | Cutter material | Cr12 , quenched | |||||

| 17 | Cr-Plating Size | 0.05mm | |||||

| 18 | Overall Size | 3000×800×1000mm | |||||

| 19 | Total Weight | 2T | |||||

| 20 | Components | Manual Uncoiler -------------------1 set Guiding Platform------------------1 set Coil Strip Leveler------------------1 set Main Machine of Roll Forming------1 set Electric-Motor---------------------1 set Cutting Device--------------------1 set Hydraulic Station------------------1 set PLC Control-----------------------1 set Supporter Table-------------------1 set | |||||

| 21 | Workflow | Manual decoiling----feeding and guiding----roll forming----cut to length----run out table | |||||

| 22 | Package | nude in the container | |||||

| 23 | Minimum order quantity | 1 set | |||||

| 24 | Payment terms | T/T(30% T/T pay in advance, the remaining 70% pay before ship) | |||||

| 25 | Delivery time | 30 working days later after receiving the deposit | |||||

| All technical parameters can be changed, according to user's need. | |||||||

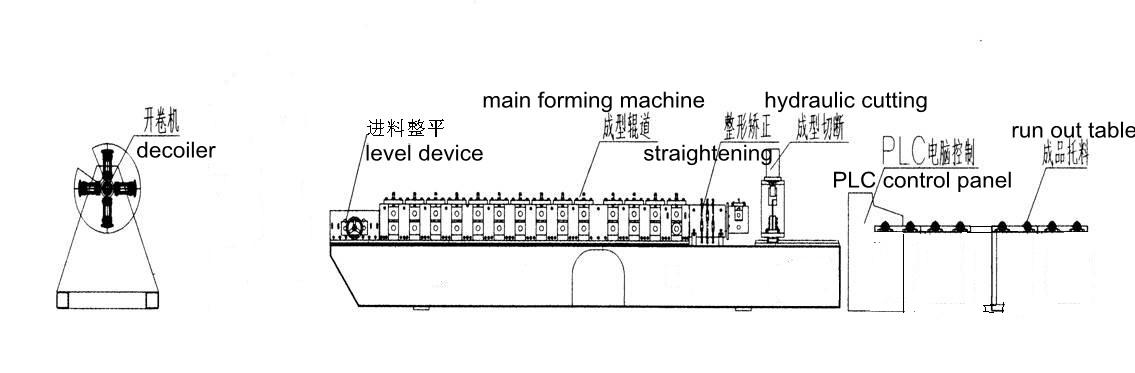

Working Flow

De-coiler—→level device—→main forming machine—→straightening—→hydraulic Punching —→hydraulic cutting—→ run out table

Machine Componnets

Machine Componnets

| Name | Quantity |

| Decoiler | 1 set |

| Level device | 1 set |

| Main forming machine | 1 set |

| Hydraulic punching | 1 set |

| Hydraulic cutting machine | 1 set |

| Cutting blades | 5 sets |

| Straightening | 1 set |

| PLC Control Panel | 1 set |

| Run out table | 2 sets |

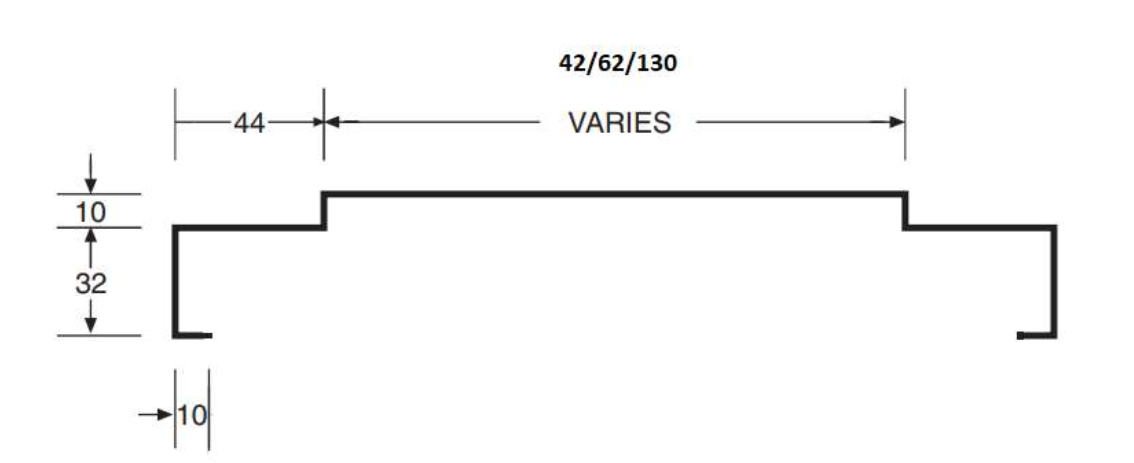

Profile drawing

Machine pictures

Quality Control

1.We strictly control the quality of raw materials and we can offer

inspection certificate of our raw materials for you.

2. We do manufacturing strictly according to the technological

processes. Besides, we carry out sampling inspection for our

products.

3. All of our workers have received relevant quality management

training so that the quality of products can be ensured.

Our goal is to offer the best solution for our customers, supply

high quality machine and good service with reasonable price. We

sincerely hope to cooperate with worldwide customers for mutual

success.