Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

15KW Automatic C and Z Shaped Steel Quickly Change Purlin Roll

Forming Machine

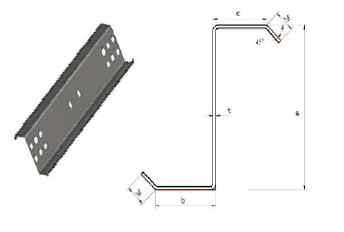

C Z Purlin Technical Parameter

| Item | Parameter | |

| Material Thickness | 1.5-3.0mm | |

| Size of C purlin | 80-300mm | |

Power Specs | Voltage | 380V/3PH/50HZ |

| Main Motor | 11kw | |

| Hydraulic motor | 7.5kw | |

| Hydraulic pressure | 10-12MPa | |

Machine Specs | Main forming stations | 18 steps |

| Forming Shaft | diameter 75 mm, 45# steel thermal refining | |

| Roller Material | GCR15 bearing steel quenching HRC58-60° | |

| Blade material | Cr12 mould steel with quenched treatment60-62° | |

| Punch Mould (if needed) | Cr12 quenched | |

| Forming Speed | 0-15m/min | |

| Cutting system | Length-set cutting after roll formed | |

| Control System | PLC and Inverter | |

Main Components

| Equipment name | Quantity |

| 3T manual uncoiler | 1 set |

| Levelling device | 1 unit |

| Punching station | 1 unit |

| Main roll forming machine | 1 set |

| Hydraulic station | 1 set |

Hydraulic cutting | 1 set |

| Control system | 1 set |

| Run out table | 1 unit |

Working Flow

De-coiler-----feeding with guide-----punching-----roll

forming------hydraulic cutting-----production support table

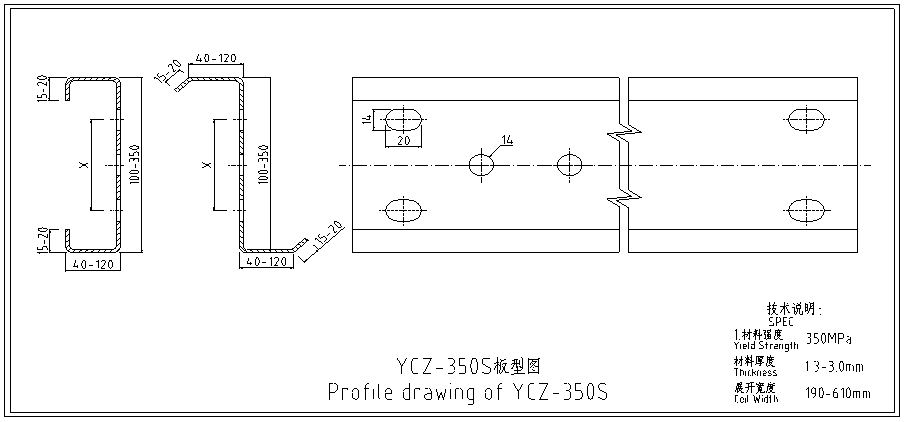

Profile and Drawing Of Product

Main features of quickly change C Z purlin roll forming machine

1.Produce different purlin size without changing rollers or

spacers.

2.No need changing cutting blade for different size.

3.Easy operation, low maintenance cost

4.Optional Punch hole at any position of purlin web side and flange

side

Our Metal C Purlin Roll Forming Machine’s advantages

1. Anti-rust roller: Cr12 mould steel with quenched treatment, long life time.

2. Heat treatment: Heat treatment for cutting frame to remove the steel stress, to avoid deformation.

3. Cutter blade: Cr12 mould steel with quenched treatment, long life time.

4. High precision: shafts for rollers are tooled by grinding machine at least twice. Rollers are CNC processed to ensure precision performance.

5. People originate: introduced Mitsubishi PLC with touch screen. Friendly man-machine interaction.

6. Excellent services: Technician can be sent to your factory to install the machine and train your workers. Lifetime services for our machines.

7. All-in-house source: We are "All-in-house source" factory to ensure quality and delivery of your machines.

8. Long life: Ensure you our produce machine’s lifetime more than 15 years.