Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

Steel silo roll forming machine

Technique parameter

| Item NO. |

Description |

Offered Specification |

1 | Suitable material thickness | 1.5-4.0mm galvanized coil S235JR |

2 | Max Material width | 1140mm |

3 | Forming Steps | 18 forming stations |

4 | Production line speed | 12-15m/min not including cutting stop time |

5 | Material of Roller | Gcr15, Quench HRC58-62 Plated Chrome |

6 | Material of Shaft | 45# Advanced Steel (Diameter: 76mm), thermal refining |

7 | Driven system | Gearbox |

| 8 | Main Power with reducer | 90KW DC Motor 380V 50 HZ 3 phase

|

9 | Hole Press | Hydraulic Punching with 3 sets of dies at one time |

10 | Cutting | Hydraulic Cutting Cr12mov Quench HRC58-62 |

11 | Hydraulic Station Power: | 22kw |

12 | Hydraulic station pressure | 25-30Mpa |

13 | Control system | PLC Panasonic with tough screen |

14 | Encoder | Omron |

15 | Electric parts | Schneider |

16 | Tolerance | 6m+-1.5mm |

17 | Machine Weight | About 10 ton |

| 18 | Machine dimension | about 11500mm*1350mmm*800mm |

Machine List

Number | Machine list | Number |

1 | 5 tons manual decoiler | 1 set |

2 | Feeding&leveling device | 1 set |

3 | Gear box drive system | 1 set |

4 | Main forming machine | 1 set |

5 | Curving device | 1 set |

6 | Hydraulic Cutting device | 1 set |

7 | Out table | 2 sets |

8 | PLC control system | 1 set |

9 | Hydraulic station | 1 set |

Working Flow of Steel Silo

A.Passive

Decoiler..........................................................To

load and uncoiling material

(We also have Electric Decoiler and Hydraulic Decoiler to hold the

heavy material.)

B.Servo Feeding

Applicator............................................To feed the

material accurately

C.Hydraulic/Press

Punching...........................................To punch as

requirements

D.Roll Forming

Unit.........................................................To

roll form as requirements

E.Hydraulic

Cutting.........................................................To

cut sheets as desired length

(We also have non-stop hydraulic cutting system.)

F.Output

Table................................................................Support

the finished products

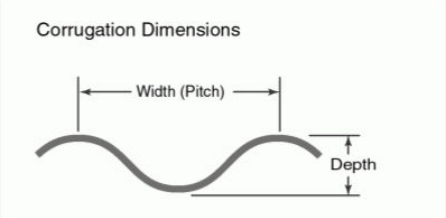

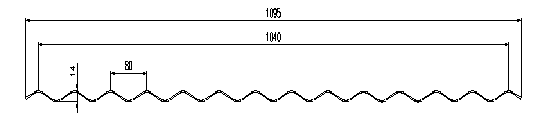

Profiles drawing of product

Machine pictures

Products