Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

PLC Control Roll Forming Equipment For Floor Decking Panel 7.5KW 380V 50Hz

all parts with the floor decking roll forming machines manufacturer

| Roll forming machine | 1 set |

| Uncoiler system | 1 set(Manual, hydraulic decoiler can be provided) |

| Entry Beach | 2 set |

| Mould | 3 set(Adjustable ) |

| Control Panel | 2 set |

| Hydraulic Station | 1 set |

| Table | 2 set(adjustable) |

| Punching system | 1 set(Depend on your need) |

the parameters of floor decking roll forming machines manufacturer

| floor decking roll forming machines manufacturer Description | Introduction |

| Working efficiency | 8-12m/min |

| Thickness of Material | 1.2-1.5mm(can be changed according to customers need) |

| Width of material | According to customers need |

| Control system | PLC(The brand can be choose) |

| Uncoiler system | 5Ton Manual Operation(1250mm width) |

| Forming by rolling | 24 rows(According to the machine design) |

| Roller material | GCR15 Aluminium processing after quenchin HRC58-62°C,Chrome plated |

| Shaft and the diameter of axle | 45#Aluminium-processing ,diameter of axle=100mm |

| Main part power | 2*11kw |

| Hydraulic motor power | 5.5kw |

| Hydraulic pressure | 12Mpa |

| Scissor material | Cr12Mov, herd steel HRC 58-62°C |

| length tolerance | ±1.5mm |

| voltage | 380V, 50HZ,3 phase(adjustable by customer needs) |

| Frame form | Middle plate |

| Driving Method | Chain |

| Color | Yellow and blue(adjustable) |

| Size | length*Width*Height - 6.8*0.8*1.2m |

| weight | about 8.5T |

| Package | Nude package in 1*40GP container |

| Delivery date | 40 working days |

| Payment Method | 30% T/T in advance and balance 70% after inspection confirmation before shipment. |

| If you have your own drawing, please send it to us, we can design the machine, depend on your drawing. | |

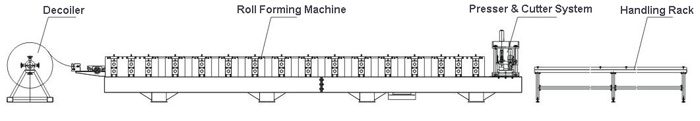

Working Flow of Roll Forming Machine

De-coiler—→Level device —→Main roll forming

machine—→Hydraulic cutting—→ Run out table