Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

Fire Damper Roll Forming Machine

Technical Parameter

| Material of coil | Material Thickness | 1.0--1.5mm |

| Un Coiler | 5 tons manual | |

| Forming system | Rolling Speed | About 10m/min |

| Roller Stations | About 16 stations | |

| Roller Material | Gcr15 coated with chrome

| |

| Shaft diameter | 65mm | |

| Maim Motor Power | 11kw | |

| Pinching motor | 2.2kw | |

| Motor cutting Power | 7.5kw | |

| Cutting system | Material Of Cutting | CR12mov with quench treatment |

| Hardness | HRC58-62 | |

| Tolerance | +-1.5mm | |

| Cutting blades | 3 sets | |

| Electrical control system | Electric Source | 380V, 50HZ,3 phase Also can satisfy Customer’s requirey |

| Control System | PLC (Panasonic) as list in the note | |

| Weight | About 8 tons | |

| Way Of Drive | 1.2 inch chain |

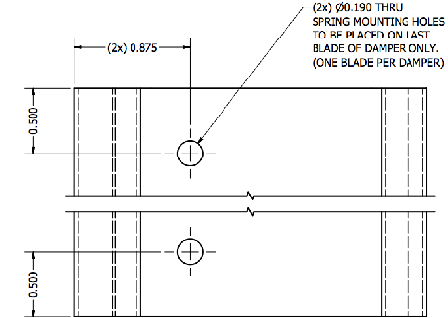

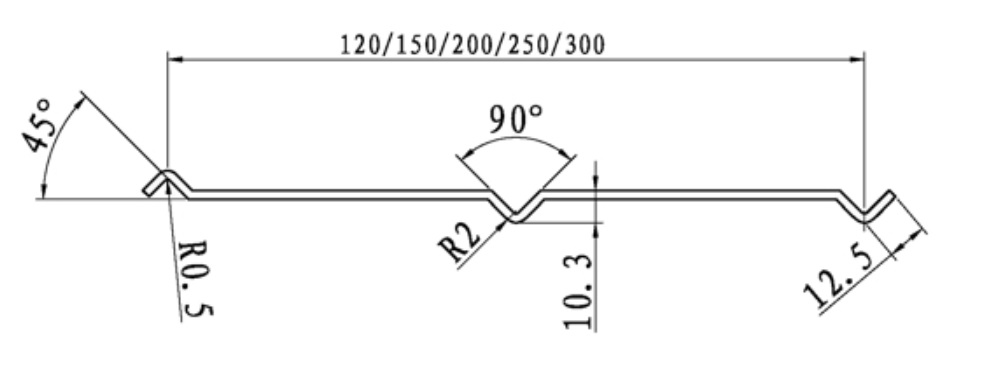

Fire Damper Main Components

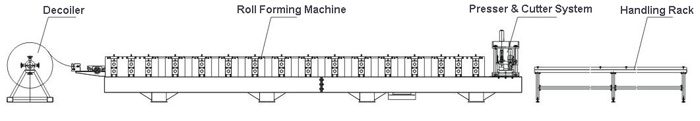

Working Flow of Fire Damper

De-coiler—→Level device —→Main roll forming machine—→Hydraulic cutting—→ Run out table

Profile of product

Loading picture

After-sale Serive

- The seller take responsibility to installation and commissioning

of the equipment and free training. After machine arrive the

destination, by the request of the buyer , the seller will provide

1 technical engineer to guide installation and training , and the

buyer should give the technical person with full cooperated.

- Installation period: about 5 days after the complete preparation

by the buyer such as the foundation and all necessary accessories.

- Training time: 5 days.

- Before departure of the engineers from seller, the buyer should

pay for installation and commissioning fee 100$/day to the point

account of the seller. The two-way ticket,visa, food, hotel , the

translator and insurance are all should provide by buyer with full

responsibility.

-The seller supply technical data (including forming mould drawing,

electrical elements drawing and equipment drawing etc.)