Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

Metal roof panel roll forming machine

Technical Parameter

Item NO. |

Description |

Offered specification |

1.1 | Rolling speed | UP to 12 m per min |

1.2 | Rolling thickness | 0.25--3.0mm |

1.3 | Raw material | Quench HRC Plated Chrome |

1.4 | Dimension | 8000mm×1600mm×1200mm |

1.5 | Effective width | 836mm |

1.6 | Feeding Coil width | 1000mm |

1.7 | Roller stations | About 18 stations |

1.8 | Roller material | 45#forge steel, coated with chrome |

1.9 | Shaft diameter | Φ76mm |

1.10 | Transmission | By chain 1.2 inch |

| 1.11 | Material of chain | 45# forged steel with frequency quenching, 12A |

1.12 | Material of cutting | Cr12Mov with quench HRC58-62° |

1.13 | Tolerance | 10m+-1.5mm |

1.14 | Hydraulic station | 4kw |

Main Components

| No. | Name | Quantity |

| 1 | 3 T manual de-coiler | 1 unit |

| 2 | Main forming machine | 1 unit |

| 3 | Control box | 1 unit |

| 4 | Hydraulic station | 1 unit |

| 5 | Out tables | 2 units |

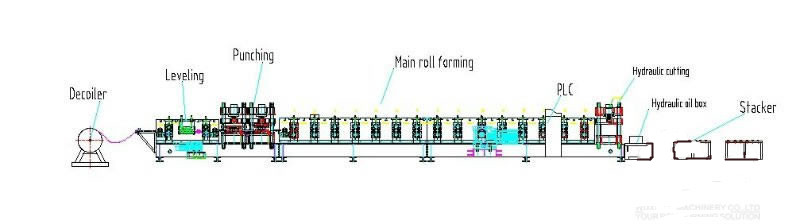

Roll Forming Machine Working Flow

De-coiler—Level device —Main roll forming machine—Hydraulic cutting— Run out table

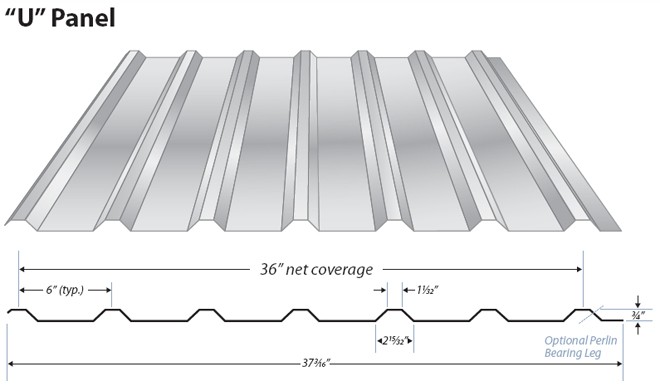

Standard Drawing of Product

Sample U Type Pannel

Customer Visiting

After-sale Serive

- The seller take responsibility to installation and

commissioning of the equipment and free training. After machine

arrive the destination, by the request of the buyer , the seller

will provide 1 technical engineer to guide installation and

training , and the buyer should give the technical person with full

cooperated.

- Installation period: about 5 days after the complete

preparation by the buyer such as the foundation and all necessary

accessories.

- Training time: 5 days.

- Before departure of the engineers from seller, the

buyer should pay for installation and commissioning fee 100$/day to

the point account of the seller. The two-way ticket,visa, food,

hotel , the translator and insurance are all should provide by

buyer with full responsibility.

-The seller supply technical data (including forming

mould drawing, electrical elements drawing and equipment drawing

etc.)