Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

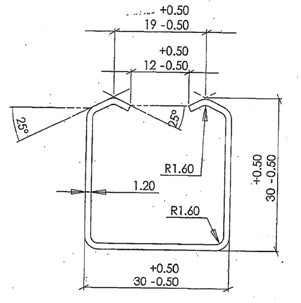

Fly Saw Door 12 Stations Roll Forming Machine PLC Control System

Door Rail Technical Parameter

1. Number of forming groups: 12groups

2. The machine material: welding comprise of 12 square tube

3. The wallboard: processing compose of 20mm steel plate

4. The mold: The mold is made of Gcr12mov steel, processed after rough turning, finish turning, finish grinding,

hard chrome plating to ensure that the mold no deformation, glabrous, wearable and accurate.

5. The shaft: The shaft is made of 45#steel, diameter of 38mm, finish turning, finish grinding after heat

treatment, quenching and high temperature tempering.

6. The bearing: Harbin type 6207

7. The roll material: 0.7-1.0mm color steel sheet, galvanized steel sheet, aluminium sheet, expansion

material 125mm, ejection of compact effective area is 88-90mm.

8. Motor: 4kw * 1 set (380v)

9. Transmission: 1.0 inch chain

10. Discharge rack: 1 set

11. Machine feature: PLC NC frequency electrical boxes, touch screen`s display, the encoder counting,

the length and quantity of the material is controllable, accuracy with in 1.0mm, automatic hydraulic cut.

Door Rail Main Components

| S.N | Equipment name | Quantity |

| 1. | 3T passive un-coiler | 1 set |

| 2. | Feeding and leveling device | 1 set |

| 5. | Main roll forming machine 12 stations drived by chain

| 1 set |

| 6. | Hydraulic cutting | 1 set |

| 7. | Control system (including control box) | 1 set |

| 8. | Out tables | 2 sets |

| 9. | Water cooling system | 1 set |

Advantage for Door Rail

1. Reasonable Price

2. High Quality

3. More Than 10 Years Experience

4. Durable

5. Reliable

Working Flow of Door Rail

Decoiler----Feeding and Leveling---Roll

forming---Cutting---Run out tables

Profiles of Door Rail

Production process

Customer visiting

Exhibition