Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

Technique data

rolling shutter door machine specification:

1. Number of forming groups: 12groups

2. The machine material: welding comprise of 12 square tube

3. The wallboard: processing compose of 20mm steel plate

4. The mold: The mold is made of Gcr12mov steel, processed after rough turning, finish turning, finish grinding, hard chrome plating to ensure that the mold no deformation, glabrous, wearable and accurate.

5. The shaft: The shaft is made of 45#steel, diameter of 38mm, finish turning, finish grinding after heat

treatment, quenching and high temperature tempering.

6. The bearing: Harbin type 6207

7. The roll material: 0.7-1.0mm color steel sheet, galvanized steel sheet, aluminium sheet, expansion

material 125mm, ejection of compact effective area is 88-90mm.

8. Motor: 4kw * 1 set (380v)

9. Transmission: 1.0 inch chain

10. Discharge rack: 1 set

11. Machine feature: PLC NC frequency electrical boxes, touch screen`s display, the encoder counting,

the length and quantity of the material is controllable, accuracy with in 1.0mm, automatic hydraulic cut.

12. Machine Length: 4.0 m * 0.5 m * 0.8 m

13. Machine Weight: 1.8 tons

14. Production time: 20 days

15. One year warranty

Standard Profile :

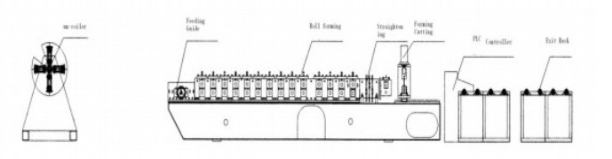

Working flow

De-coiler—→level device—→main roll forming machine—→punching—→ hydraulic cutting—→ run out table

3T Passive De-coiler

Diameter: 460-520mm expansion.

Expansion: Manually

Capacity: 3000kg per mandrel

Leveling device

2 rolls leveling, 1 rolls up and 1 rolls down

Diameter is Ø 70mm, chrome and HRC60 heat treatment to secure the smooth surface

Leveling Raw Material thickness:0.3-0.8mm

Max Leveling Raw Material width: 300mm

Hydraulic station

hydraulic station pressure: 12MP

power of hydraulic station: 4KW

main roll forming machine

1 Materials to form shutter door: 0.8-1.2mm galvanized coils, Feeding width: 114mm

2 Forming steps: about 12 steps

3 Material of rollers: GCr15 steel, precision-machined, high frequency quenching HRC58-62, diameter of rollers: >¢150

4 Material of main shaft : 45# high quality steel (diameter>¢50)

5 Chains’ material: 45# steel, high frequency quenching, circular pitch:38.1; number of teeth: 13

6 Cutting: hydraulic cutting; quenching HRC58-62

7 Electronic control: PLC control Panasonic Brand

8 Dimension of machine: 3500mmX500mmX800mm

9. Working speed:12-15m/min;

10 Drive system: chain drive, 5.5KW main motor power,

Hydraulic Cutting:

5.1 The cutter blade material: Cr12mov HRC58-62 degree

5.2 Blades number: 2 sets

5.3 Cutting after forming: Cut the sheet after roll forming to required length

5.4 Cutting motion: The main machine automatically stops and the cutting will take place. After the cutting, the

main machine will automatically start.

5.5 Material of blade: CR12with heat treatment

5.6 Length measuring: Automatic length measuring

5.7 Tolerance of length: 6m+/- 0.5mm

Output Table:

Length : 2m

Quantity: 2 units

Control system: Panasonic Brand PLC control box

(1) Power supplier: 410 V, 50 Hz, 3Phase (adjusted with the requestment)

(2) Length & quantity measurement automatically;

(3) Length & quantity controlled by PLC,

(4) Length inaccuracy can be amended easily.

(6). Control panel: Button-type switch and touch screen

(7) The language in the touch screen: English and Chinese

(8) Unit of length: millimeter (switched on the control panel)

Company Introduction

Sussman Machinery (wuxi) Co., Ltd. is a comprehensive enterprise integrating production, sales and services. We are mainly engaged in providing machineries and equipment. Owing to a professional teamwork, we are experienced in manufacturing, import and export, customers' design, installation and test, technical solution and after-sale services. We have shipped out our machines to more than 50 countries, and keep good business relationships with a large amount of worthy customers, contributing to our great business records and reputation.