Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

3.5 Tons Wall Angle Channel Roll Forming Making Machine Forming

Speed 20 m Per Minute

Wall angle introduction

The Wall Angle Channel Roll Forming Machine can produce

different kinds of angle steels, which produces thickness

of 0.4-1.2mm steel coils. The number of roll forming stations is

aout 9 stations, or according to your profile drawing. We can

design the machine and flow chart according to your profile drawing

and requirements. We also have several feeding

systems and hydraulic punching systems which can satisfy your

complex punching requirements.

Technical Parameter

| Material Thickness | 0.4-1.2 mm |

| Rolling Speed | About 20 m/min line speed |

| Roller Stations | About 9 stations |

| Roller Material | 45# Steel with quenching 60mm shaft |

| Maim Motor Power | 5.5 kw |

| Hydraulic cutting Power | 4 kw |

| Material Of Cutting | CR12 with quench treatment |

| Hardness | HRC58-62 |

| Tolerance | +-1.5mm |

Electrical control system | Electric Source | 380V, 50HZ,3 phase |

| Control System | PLC control system |

| Weight | About 3.5 tons |

| Way Of Drive | 1 inch single chain |

| Size of machine | Length 4500mm* Width 500mm* Height 800mm |

Working process

A.Passive

Decoiler..........................................................To

load and uncoiling material

(We also have Electric Decoiler and Hydraulic Decoiler to hold the

heavy material.)

B.Servo Feeding

Applicator............................................To feed the

material accurately

C.Hydraulic/Press

Punching...........................................To punch as

requirements

D.Roll Forming

Unit.........................................................To

roll form as requirements

E.Hydraulic

Cutting.........................................................To

cut sheets as desired length

(We also have non-stop hydraulic cutting system.)

F.Output

Table................................................................Support

the finished products

Decoiler—feedingwithguide—Rollforming—Cutting—Products collecting

Machine Components

| 1 set |

| 1 set |

| 1 unit |

| 1 unit |

| 2 units |

| 1 unit |

| 1 unit |

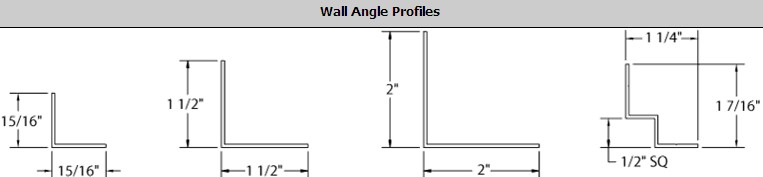

Profile of product

Machine Photo