Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

door frame roll forming machine

Technical Parameter

1.Suitable Plate Material: thickness 1.5-2.0mm, Galvanized steel or

blank steel

2. Working Speed: 12-15 meters / min

3. Forming Steps: 18 stations

4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5. Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal

refining

6. Driven system: gear box drive

7. Main Power with reducer:15KW WH Chinese Famous

8. Cutting: Hydraulic Cutting Cr12mov

9. Material of Cutting Knife: Cr12Mov, Quench HRC58-62

10. Hydraulic Station Power: 7.5KW Wuxi Wanshen Famous Chinese

Brand

11. The whole machine is controlled by industry computer-PLC.

12 PLC--Siemens, Japan English and Chinese Language

13 Touch Screen-- Siemens Japan

14. Encoder--Omron, Japan

15 Electric parts--Schneider

16 Machine direction: from Right to Left

Main Components

Machine list |

5 ton passive de-coiler |

1 set |

Leveller |

1 set | |

Punching |

4 sets | |

Main roll forming machine |

1 set | |

PLC Control box |

1 unit | |

Hydraulic station |

1 unit | |

Out table |

2 units |

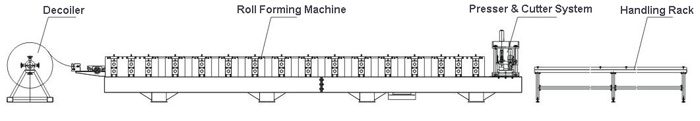

Working Flow of Roll Forming Machine

A.Passive

Decoiler..........................................................To

load and uncoiling material

(We also have Electric Decoiler and Hydraulic Decoiler to hold the

heavy material.)

B.Servo Feeding

Applicator............................................To feed the

material accurately

C.Hydraulic/Press

Punching...........................................To punch as

requirements

D.Roll Forming

Unit.........................................................To

roll form as requirements

E.Hydraulic

Cutting.........................................................To

cut sheets as desired length

(We also have non-stop hydraulic cutting system.)

F.Output Table................................................................Support the finished products

Decoiler—Level device —Main roll forming machine—Hydraulic cutting—Run out table

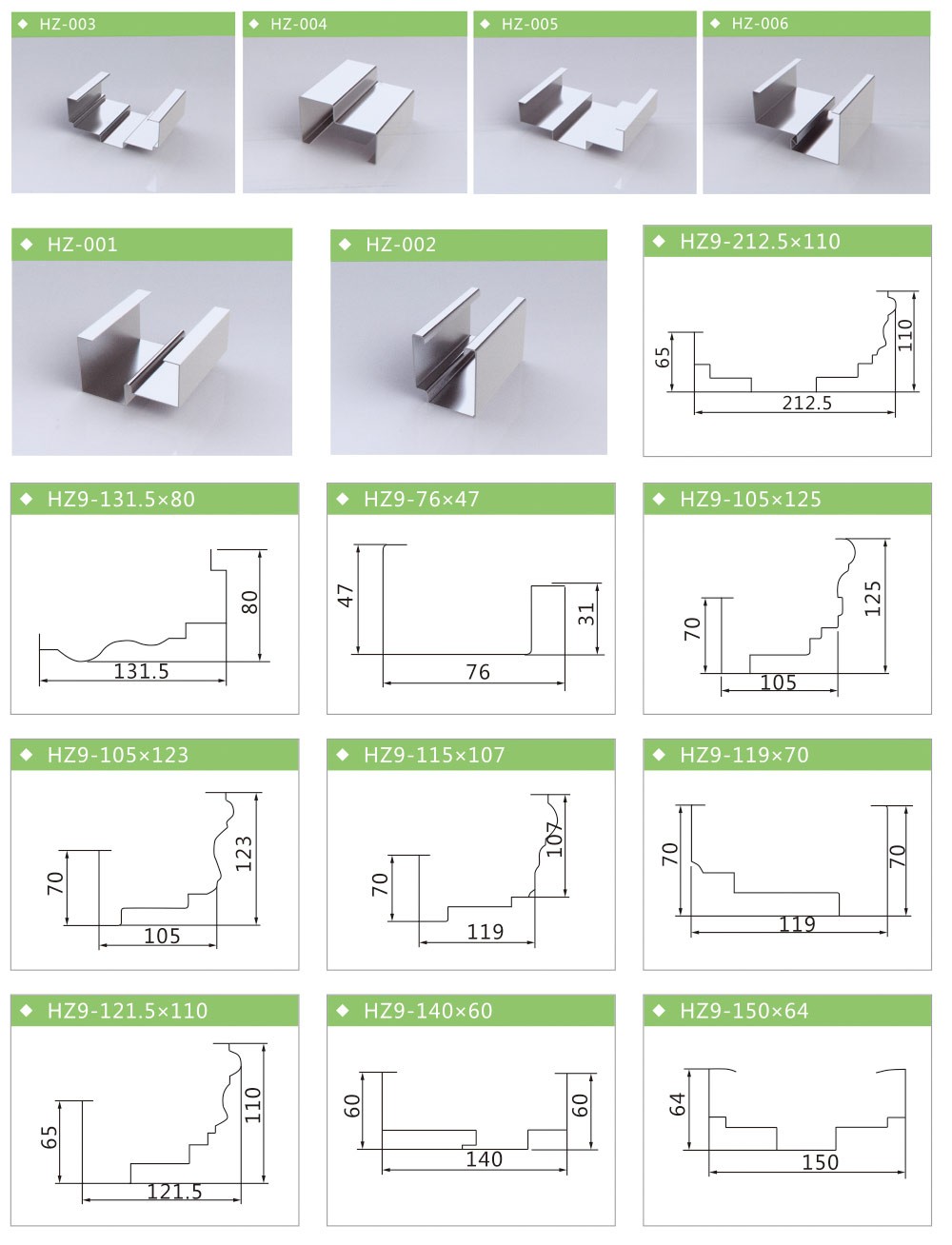

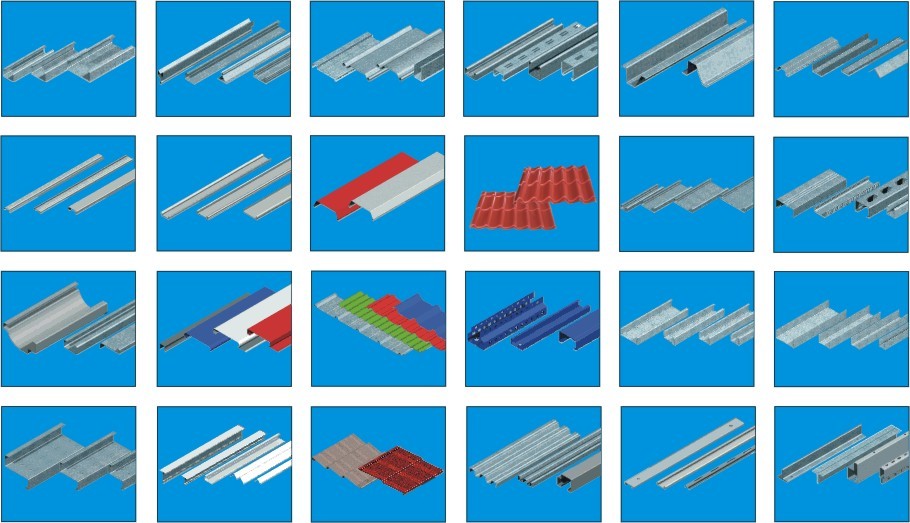

Profile of product

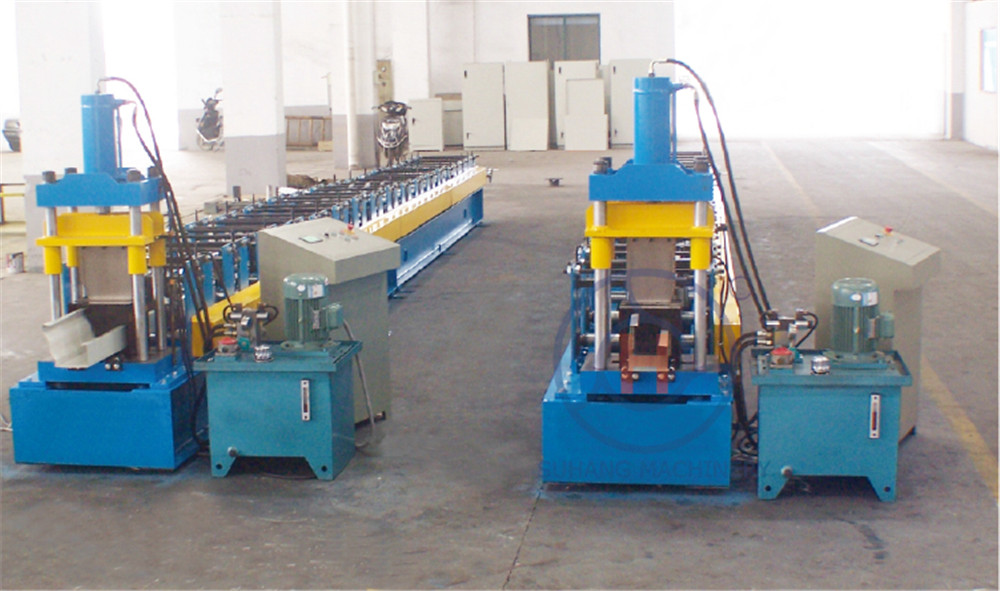

Photo Gallery

Loading pictures

Company Profile

Sussman Machinery (wuxi) Co., Ltd. is specialized in building materials of light steel structure. Since the factory founded 10 years before, it always designs and produces various type profile

of roll forming machine.

The main products of factory is Roller shutter door, PU sandwish panel line, pre-painted steel forming machine, Racking roll forming machine, the cable tray roll forming machine, Glazed Tile forming machine, Automatical C/Z Purlin forming machine, Floor Deck forming machine, Guardrail forming machine, Down

Pipe forming machine, the whole carriage plate for car beam unit, Steel storage unit, etc. The products

are widely used in warehouse, factory buildings, supermarket, Nursing homes, villas and other

construction projects, Our factory can meet the construction enterprises, automobile industry, Iron and

steel production enterprises' growing demands.

Sussman machinery is located in Wuxi city, Jiangsu province which is close to Shanghai, It's about half an hour's journey. We enojoy the convenient transportation and advantageous location which supply good business opportunities for the buyers home and abroad.