Sussman Machinery(Wuxi) Co.,Ltd |

|

Verified Suppliers

|

|

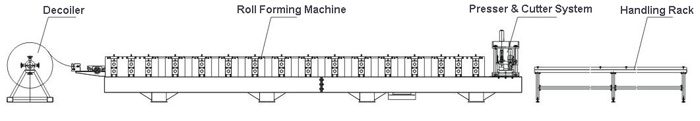

Drywall C U stud track frame roll forming machine

Technical Parameter

1. Roller stations: 13 stations

2. Rorming speed: 8--20 m/min

3. Material thcikness: 0.4-1.2mm

4. Roller material: GCr15, HRC55-60

5. Shaft diameter: 60mm

6. Shaft material: 45# steel

7. Main motor power: 7.5Kw

8. Hydraulic station: 4Kw

9. PLC: Panasonic

10. Machine size: 6000mmx 800mm x 900mm

11. Machine weight: 3 tons

12. Cutting blade material: Cr12Mov

13. Drive way: 1 inch chain drive

14. Cutting: hydraulic cutting

Machine List

| Machine list |

3 ton passive de-coiler | 1 set |

Feeding with guide | 1 set | |

Main roll forming machine | 1 set | |

PLC Control box | 1 unit | |

Hydraulic station | 1 unit | |

Stop cutting device | 1 unit | |

Safety cover | 1 unit | |

Out table | 2 units |

Main features and components of the machine

1.Simple structure & beautiful appearance, because we adopt the shape-steel structure and process as a whole after welding. It has the ability of strong loading and stable operation

when running the machine.

2.All the components of machine are from brand-famous enterprise so that they ensure the machine normal function very effectively.

3.We adopt the automatic length- fixed forming and cutting to guarantee the length to be precise and the finished product clear without

deforming.

4. It is very easy to install the equipment and suitable for producing in the factory.

5. The machine has features of low noise and high efficiency.

Technological process

Decoiler—feeding with guide—Roll forming——Cutting—Products collecting

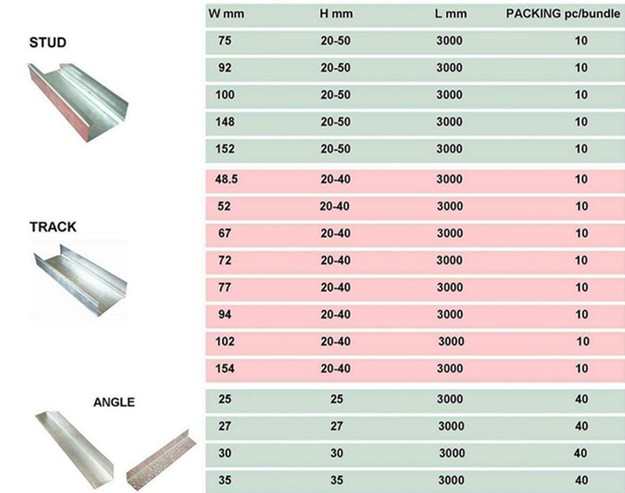

Profile of product

Machine Photo

Loading pictures

Company Profile

Sussman Machinery (wuxi) Co., Ltd. is specialized in building materials of light steel structure. Since the factory founded 10 years before, it always designs and produces various type profile

of roll forming machine.

The main products of factory is Roller shutter door, PU sandwish panel line, pre-painted steel forming machine, Racking roll forming machine, the cable tray roll forming machine, Glazed Tile forming machine, Automatical C/Z Purlin forming machine, Floor Deck forming machine, Guardrail forming machine, Down

Pipe forming machine, the whole carriage plate for car beam unit, Steel storage unit, etc. The products

are widely used in warehouse, factory buildings, supermarket, Nursing homes, villas and other

construction projects, Our factory can meet the construction enterprises, automobile industry, Iron and

steel production enterprises' growing demands.

Sussman machinery is located in Wuxi city, Jiangsu province which is close to Shanghai, It's about half an hour's journey. We enojoy the convenient transportation and advantageous location which supply good business opportunities for the buyers home and abroad.

Our After-Sales Service Commitments

Sussman hereby solemnly promises: We implement the “three guarantees” service policy for any equipment sold by Sussman, provide free of charge installation guidelines, commissioning and maintenance of the equipment, training of the Buyer’s relevant Operators; and provide technical requirements for the installation and operation of the equipment, technical layout diagrams and other related information, provide a lifetime supply of maintenance and spare parts

The detailed measures are as follows:

1.Guidelines for installation and commissioning of equipment:

Based on the actual situation, to assist and guide the Buyer and Buyer’s technical personnel in the overall installation location, the installation of equipment, and provide Buyer with answers to their questions and related issues;

2.Provide training for operation and maintenance personnel:

Based on the Buyer’s request, Sussman will provide free of charge training of the operation and maintenance personnel;

a) The User (Buyer) can send their operation and maintenance personnel to our factory for learning and training;

b) When Sussman is doing the installation and test running of the equipment for the Buyer, the Buyer can send their personnel to participate.

3.If failure occurs in any of the machines during the “three guarantees” period(one year), then, upon the Buyer’s request, Sussman will eliminate the failure;