Cangzhou Authentic PIPE-FITTING Manufacturing Co., Ltd. |

|

Verified Suppliers

|

|

Stainless Steel Elbow AISI SS321 316 304 Stainless Steel Seamless Welded Elbow

The main difference between stainless steel elbow and other elbows

is the material difference. The chemical composition contained in

the stainless steel elbow will keep the surface of the stainless

steel elbow from rusting and corrosion for a long time.

In the pipeline system, a stainless steel elbow is a pipe fitting

that changes the direction of the pipeline. According to the angle,

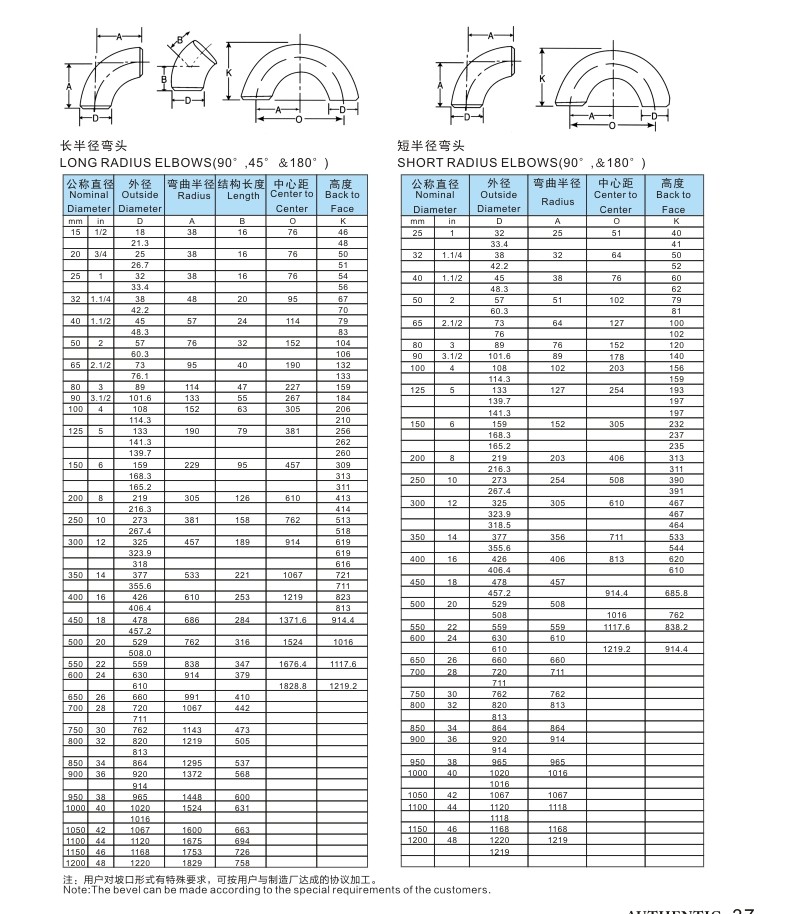

there are three kinds of 45° and 90°180°. In addition, it also

includes other abnormal angle elbows such as 60° according to

engineering needs.

The ways to connect with the pipe are direct welding (the most

common way) flange connection, hot melt connection, electrofusion

connection, threaded connection, and socket connection. According

to the production process, it can be divided into welding elbow,

stamping elbow, push elbow, casting elbow, butt welding elbow, etc.

Other names: 90-degree elbow, right angle bend, etc.

Stainless steel elbow is in the pipeline system, bend is the pipe fitting that changes pipeline direction. Points according to the Angle 45 ° and 90 ° 180 ° three kinds of commonly used, according to the requirements of the project also include 60 °, and other abnormal Angle bend. Stainless steel elbow is different from carbon steel elbow, which is mainly made of materials. Its chemical composition will keep the curved surface for a long time without rust and will not be corroded.

According to the standard production can be:

1. The division of manufacturing standards can be divided into national standards standards, electric standards, water standards, American standards, German standards, Japanese standards, Russian standards, and so on.

2. It can be divided into two categories: push, press, forging, and casting.

90 ° bend is mainly used for stainless steel pipe installation, a connecting pipe used for connection pipe bend. Connect two of the same or different nominal diameter tubes, and make the line turn 90 °.

Stainless steel

It is usually added to the carbon steel based on the high proportion of Cr, Ni, and other alloys, the content proportion can reach over 20%. The common types of steel are 304,304 L, 321,316,316 L, 1Cr18Ni9Ti, 0cr18ni9, the first several steel Numbers expressed in the number of Numbers as Japan, the American steel signal method, and the latter one (1Cr18Ni9Ti) as the domestic steel number method.

Features: Stainless steel's strength and toughness index are good in all kinds of steel, The most prominent advantage is corrosion resistance, in the chemical industry, papermaking and other corrosive strong occasion must be used in stainless steel, Of course, the cost is higher!

Stainless steel elbow is different from carbon steel elbow, which is mainly made of materials. Its chemical composition will keep the curved surface for a long time without rust and will not be corroded.

The use and maintenance of the stainless steel elbow requires a lot of attention, which requires users to use it according to certain methods and use and maintain it by accurate and reasonable methods. Precautions are as follows:

1. Long-stored stainless steel elbow, should be timely check, often appears the processing surface should be clean, removed dirt, and neatly stored in a dry indoor drafty place, it is strictly prohibited from stacking or in the open air. Always keep the drying and ventilation of the stainless steel elbow, keep the device clean and tidy, and store it according to the accurate storage method.

2. When installing, the stainless steel elbow can be installed directly on the tube by connecting mode, and installed according to the position used. In general, can be installed on the pipeline at any position, but needs to be tested for easy manipulation, should pay attention to the flow direction of the medium by the stainless steel elbow is high, the longitudinal disc below the stainless steel elbow can only be installed horizontally. The stainless steel elbow should be attentive to the seal during installation to prevent leakage and affect the normal operation of the pipe.

3. The ball valve of the stainless steel elbow, and globe valve, when used by the gate valve, can only be fully open or fully closed and does not agree to regulate the flow, to prevent the sealing cover from erosion and accelerate wear and tear. The gate valve and the upper thread globe valve have a back sealing device, and the handwheel is screwed to the top position to prevent the leakage of the medium from the filling.

4. Use a handwheel for the stainless steel elbow, do not use a lever or other tool to avoid damage to valve parts. The handwheel turns clockwise to be closed, and vice versa. The use of children should be reasonable, ensuring accurate use of methods and means.

5. The bolts of the packing gland of the stainless steel elbow should be tightened on average and should not be compressed into an Angle so as not to hurt the stem movement or cause leakage.

6. In the process of use, the stainless steel elbow should always be kept clean, and the transmission thread must be lubricated in time. When the fault is found, it should be stopped and used immediately, and find out the reason for the failure.

The machining method of stainless steel elbow fitting

There are many kinds of machining methods for stainless steel elbow fittings. Many of them belong to the category of mechanical processing. The most used are stamping, forging, rolling, rolling, rolling, stretching, bending, and combining. Pipe fitting is an organic combination of machining and metal pressure machining. Forging press: The pipe end or part of the pipe is extended by a type forging machine to reduce the outer diameter and the common type forging machine has a rotary type, connecting rod type, and roller type. Punching method: The tube end is extended to the required size and shape with a tapered core in a stainless steel elbow. Roller method: In the stainless steel punching elbow, the core is placed, and the outer circumference is pushed by the roller to be used for round-edge processing.

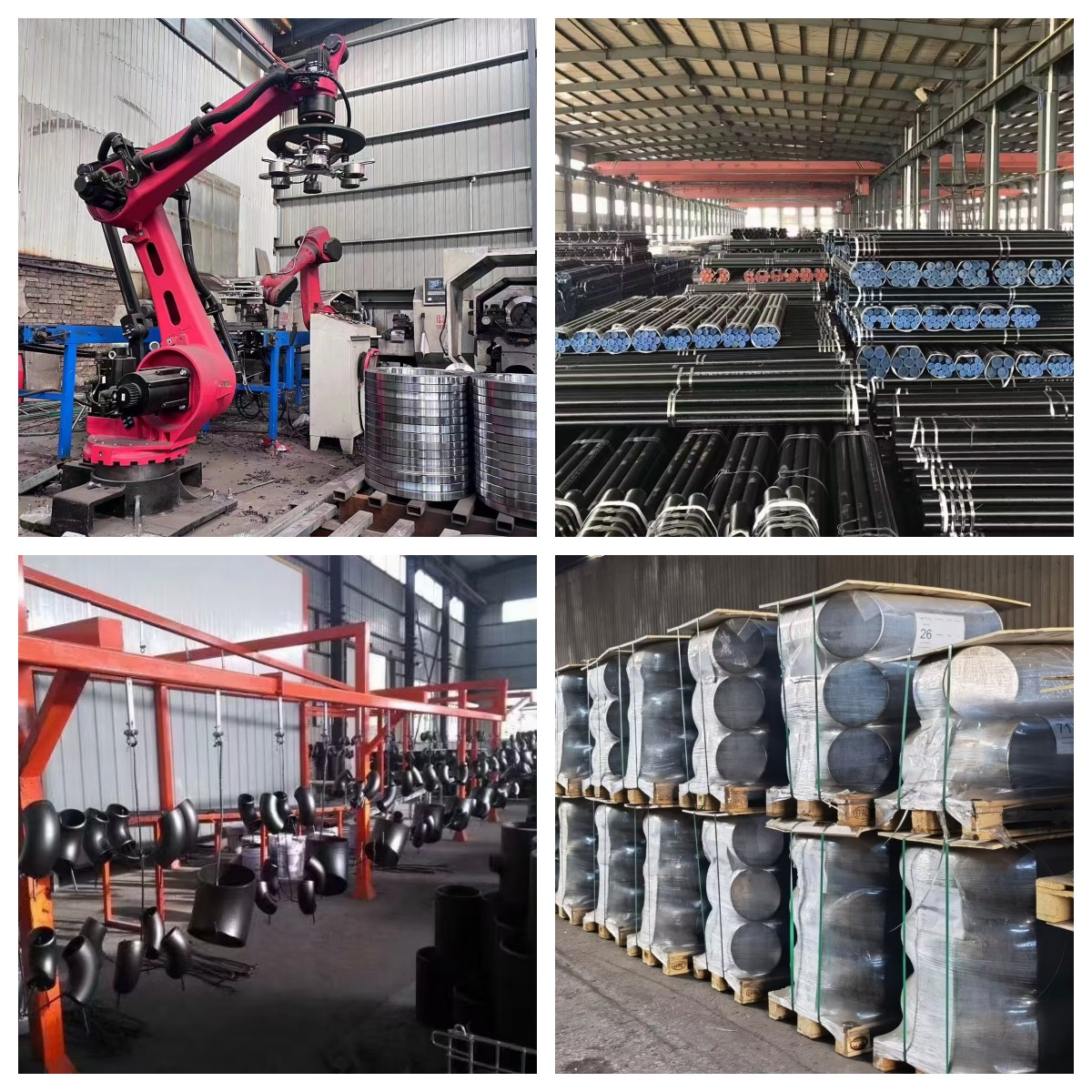

About Us:

Cangzhou authentic Pipe-Fitting Manufacture Co.,ltd.Possesses a site of 150000 square meters, with a building of 50000 square meters, and permanent assets of 78 million. The number of staff reached 134. Among them, are 26 technicians, The corporation has employed 15 pipe-fittings manufacturing and flanges-making production lines. The techniques, such as beaten, forging, and machine-processing. intermediate-frequency pushing, cold-molding, high extruding, and heat treatment, are all available in our mill, In addition, more and more attention is paid to the improvement of inspecting equipment with the sole purpose of ensuring the quality of our products. Advanced Equipment as well as corresponding detecting skills have been adopted constantly, such as Chemical Elements Analyzing, Metal Test, physics inspecting, and Nondestructive Detecting. Besides, we have employed the most advanced Material Composition analyzing equipment Spectrum Direct-reading Equipment(made in England)with its chemical composition of all kinds of metal material that could be tested directly and exactly.

Our Certificate:

1. Are you a trading company or manufacturer?

We are manufacturer

2. How long is your delivery time?

Generally, it is 10-15 days if the goods are in stock. or it is

10-15 days if the goods are not in stock, it is according to

quantity.

3. Do you provide samples? is it free or extra?

Yes, we could offer the sample for free charge but need to pay the

cost of freight.

4. What are your terms of payment?

Payment of 30% T/T pay in advance, the balance should be paid

against the copy of B/L

WhatsApp:+86 15688790927