Qingdao Ruly Steel Engineering Co.,Ltd |

|

Verified Suppliers

|

|

Concrete Batching Plant/Prefabricated Heavy Steel Building/Industrial Steel Structure Workshop

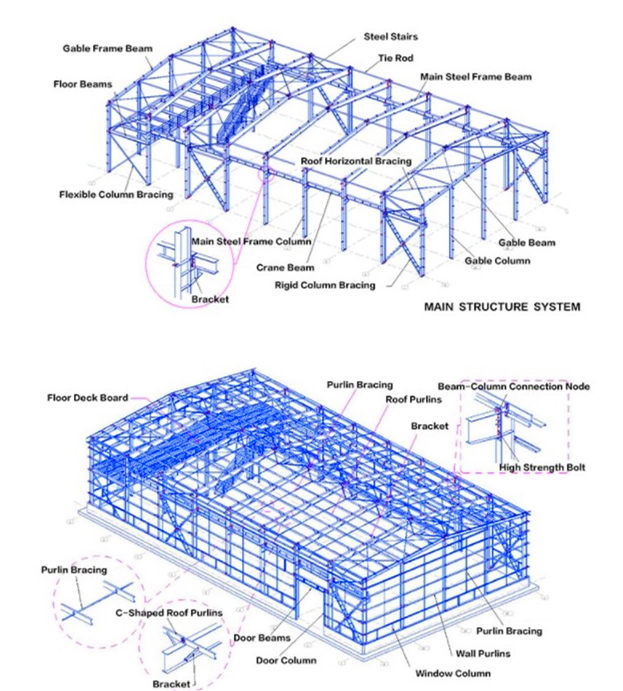

Concrete Batching Plant/Prefabricated Heavy Steel Building/Industrial Steel Structure Workshop is a new project that we completed recently. Most industrial steel warehouse buildings are bent structures, mainly steel structures. It is mainly used for single-story steel structure workshops, which consists of trusses, columns and foundations. It is the main load-bearing system of steel structure buildings, and then the bent structure are joined by longitudinal members such as roof panels, crane beams, and supports to form an overall space structure to connected to form the overall spatial structure.

The steel structure building is widely used in the construction of

buildings such as warehouses, workshops, and large factories.

hangar,garage, exhibition hall, agricultural storage, logistic

centers etc.

| Name | Concrete Batching Plant/Prefabricated Heavy Steel Building/Industrial Steel Structure Workshop |

| Structure Type | Single ridge, double spans |

| Length | 150m |

| Width | 50m |

| Eave Height | 12m |

| Roof Slope | 10% |

| Gable Wall Column Spacing | 7.5m |

| Roof | PU sandwich panel |

| Wall | PU sandwich panel |

| Door | Sliding door |

| Window | Ribbon Skylight |

| Height difference between indoor and outdoor | 300mm |

| Main Steel Frame System | |

| Main structure | H section steel Q355, alkyd painting, two primary painting, two finish painting. |

| Roof purlin | XZ160*60*20*2.5, galvanized |

| Wall purlin | XZ160*60*20*2.5, galvanized |

| Intensive bolt | Grade 10.9 |

| Turn buckle bolt | M20+2, steel Q235, processing |

| Anchor bolt | M24, steel Q235, processing |

| Ordinary bolt | Galvanized bolt M20 |

| Ordinary bolt | Galvanized bolt M12 |

| Brace nut | Galvanized bolt M12 |

| Bracing System | |

| Cross brace | Φ20 round steel bar Q235, process and painted (alkyd painting) |

| Angle brace | L50*5 angle steel Q235, process and painted (alkyd painting) |

| Column bracing | Φ25 round steel bar Q235, process and painted (alkyd painting) |

| Tie bar | Φ127*3 steel pipe Q235, process and painted (alkyd painting) |

| Batter brace | Φ32*2.5, Φ12 round steel bar Q235, process and painted (alkyd painting) |

| Wall & Roof System | |

| Roof panel | PU sandwich panel |

| Wall panel | PU sandwich panel |

| Edge cover | 0.5mm color plate, angle Alu. |

| Fittings & accessories | Nails, glue etc. |

| Unpowered ventilator | Diameter Φ600, stainless steel |

| Sky lighting band | 1.2mm FRP, double layer |

| Sliding door | sandwich panel door |

| Roof drainage system | |

| Gutter | 0.5mm color steel plate |

| Rainspout pipes | Φ110 PVC pipe |

Qingdao Ruly Steel Engineering Co.,Ltd is a professional steel structure fabrication and construction company for light and heavy steel structure Design, Manufacture & Installation.The floor space of our steel structre fabrication factory is 35,000㎡, and the workshop area is 20000㎡. We own several light/heavy H steel production lines, BOX production lines, C/Z purlin production lines and various types of profiling steel sheet machines with advanced equipment such as plasma cutting machine.

1. Structural steel fabrication, painting , galvanizing , pre-assembly

2. Designing, fabrication and installation for Prefabricated steel structure building.

3. Deepen or design the fabrication drawing or shop drawing based on your architectural drawing and construction drawing

4. Engineering consulting service

All the structure components, panels,bolts and sort of accessories will bewell packed with standard package suitable ocean transportation and loaded into 40’HQ.

All the products are loaded at the loading site of our factory using crane and forklift by our skilled workers,who will prevent the goods to be damaged.