Jinan Dragon Steel Balls Co.,Ltd |

|

18mm Mid Chrome High Chrome Grinding Cylpebs Casting Clinder For Cement

1. Classification

According to the different chemical elements , grinding cylpebs can be divided into Low Cr,Medium Cr and High Cr. At present, the above materials are widely used all over the world, that’s the conventional materials, if there are special needs, can be customized.

2. Manufacturing process

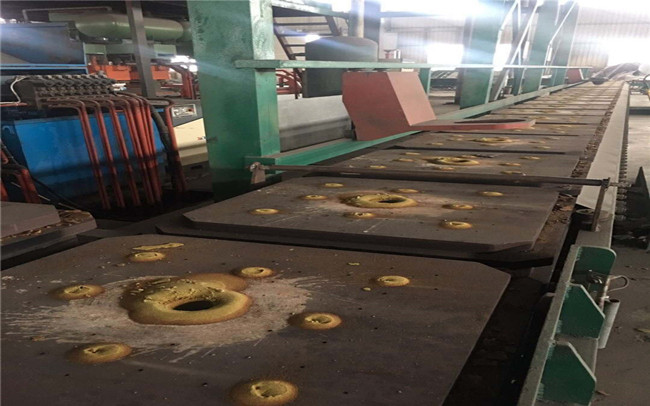

Grinding cylpebs are melted in electric furnace and poured into moulds after scientific proportioning.

3. Product Name Different Name in Different Country

Grinding Cylpebs

Casting Cylpebs

Clinder

Grinding Media Cylpebs

Grinding Medium Cylpebs

4. Application

Grinding cylpebs are used in ball mills, mainly in mines, cement plants, power plants and so on.

① Mining ( Gold, copper, iron ore )

② Cement plant

③ Coal mill

④ Sag mill

⑤ Industry

⑥ All the ball mill or rods mill machine

5. Detail Specifications

① Chemical Composition

| Material | Chemical Composition |

| Low Cr | C:2.2-3.4, Si:≤1.2, Mn:0.5-1.5, P:≤0.06, S:≤0.06, Cr:1.0-1.5 |

| Medium Cr | C:2.0-3.2, Si:<1.0, Mn:0.5-2.5, P:≤0.06, S:≤0.06, Cr:≥5 |

| High Cr | C:2.0-3.2, Si:<1.0, Mn:0.5-2.5, P:≤0.06, S:≤0.06, Cr:≥10 |

② Hardness

| Type | Low Cr | Medium Cr | High Cr |

| Grinding Cylpebs | 45-50 | 48-55 | 58-63 |

③ Grinding Cylpebs Size

16×16 |

18×18 |

18×22 |

20×25 |

20×30 |

20×35 |

22×30 |

25×25 |

25×30 |

25×35 |

30×35 |

30×40 |

35×40 |

35×45 |

6. Test

① Factory test

Grinding cylpebs test is an very important step. Real-time detection will be carried out in the production process. Cylpebs produced in each shift will be sampled in large quantities and tested for size, hardness, chemical composition, drop test, core pulling and impact value to ensure the quality of cylpebs

② The third party test

According to the customer different demand, cylpebs can be tested by any third party.

7. Packing

Cylpebs are usually packed in container bags and steel drums, it can also be customized according to different customer needs.

8. Company Introduction

Dragon balls factory are established in 2001.Up to now, we have cooperated with many large power plants in China for more than 10 years. Since 2007, Dragon balls has set up its own foreign trade team, and began to show itself to the world. The forged ball, cast ball and cylpebs are widely praised by friends at home and abroad.

Dragon balls has a very mature technology research and development

team and sales team, we are constantly expanding the factory and

team every year, in order to meet the growing demand at home and

abroad.

Steel balls are a long-term business.

We are willing to do it all the time because if we know someone, we will become permanent friends.

We can always do this for so many years because our quality supports our long-term cooperation and friendship.

The quality of every steel ball is crucial because it is a strong bridge that connects us.