Shanghai Wind Automation Equipment Co.,Ltd |

|

Verified Suppliers

|

|

DC Power Supply Spot Welding Machine For Armature Commutator Fusing Hot Staking WIND-DC-CW003

(1) Application:

PMDC motor armature with hook commutator, riser commutator

(2) Advantages:

Fusing Quality Assured |

Self-developed High frequency 15KHz power supply ensure constant

fusing quality

|

Wide Application |

Copper wire wide adaption from 0.01mm~1.20mm(AWG44~AWG17)

|

Easy to Operate |

Easy for the operator,

and WIND-DC-CW003 get most repeated order among welding machine

|

(3) History of becoming star product:

The first two pcs welding machine WIND-DC-CW003’s user was a car motor manufacturer who produce

motors and supply to BMW and Volvo, they used Italy and English imported welding machine and WIND-

DC-CW003 worked as backup machine. After several months test user found welding result and quality is

same as imported welding machine and ordered 1pc more three years later.

High frequency inverter DC power supply is a trend in commutator welding, some supplier said they use

high frequency actually they use 2KHz, while Wind Automation can achieve 15KHz, with real and pure DC

power supply which achieve constant welding quality!

(4) Fusing machine Parameter:

Wire diameter: 0.01~1.2mm

Armature OD: 20~100mm

Armature stack height:10~100mm

Commutator OD:8~70mm

Airsource:5~7KG/cm2

Welding power: 10~30KW

3phase AC 380V 50~60Hz

Weight: about 350KGS

Fusing power supply: Wind Automation self developed high frequency 15KHz, 500~5000A

Control system: Japan Mitsubishi PLC

Indexing control: Japan Mitubishi servo positioning system 7'' Touch screen

(5) Feature:

1) Commutator spot welding machine conductor hot staking Fusing for thin or big wire High frequency

inverter weld and hot stacking commutator with small big wire thin and big wire, with separate

cooling water device (act as a conditioner)

2) Welding operation is related to the tungsten rod area, pressure, welding time, voltage current value

3) Armature OD, shaft size is related to the fixture

Armature OD normal range 20~60mm

Shaft below 160mm Shaft size

Fusing machine FAQ (How to select a suitable welding fusing hot staking machine)

Your question is about achieve even and constant fusing quality for each segment,

The DC power supply machine with high requency's output current is even and constant, can make sure even welding quality,

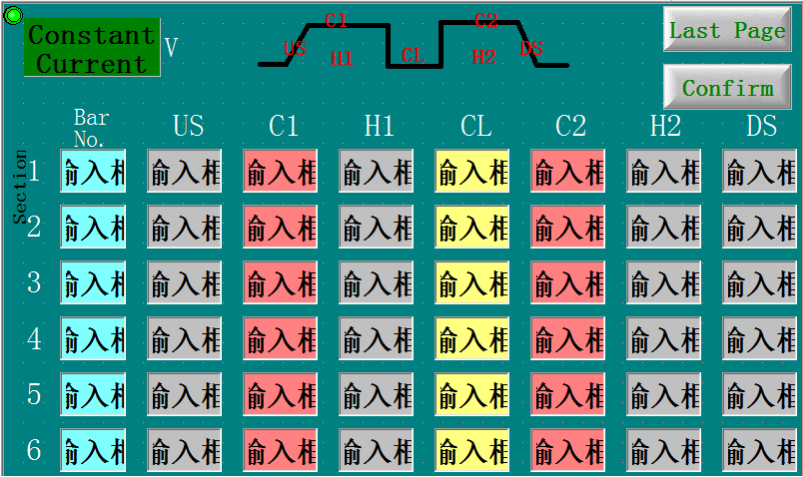

On machine parameter set screen, there is 6sections welding current and time setting for armature with many hooks such as 63hooks,

and for a 24 hook commutator, you can divide the welding parameter to 3 stages by setting Bar. no. as 1+22+1 = 24 or divide the setting to set 1+1+1+2+3+16 =24

considering heat up time for electro rod and actual situation,

In actual production, some user just set the Bar No. in Section1 as 24,

2. How electrode distance is controlled?

The distance suggested is about 1.5mm to 2mm, should be more than 1mm in case the commutator OD have some difference

You can check by a 1.5mm thickness commidity as a

3. How the pressure applied by the electrode to the hook is adjusted and controlled?

With diffent size of Press Spring the pressure can be adjusted, for rough control with spring,

for slight control with screw on top

4.Is there any load cell to control this pressure?

Yes,

Our hydraulic and servo press machine for commutator, shaft placement have this kind of load cell which can control and show pressure,

We are applying this to the new fusing machine with servo device pressure later,

This will be applied for local motor manufacturer who required first

5. What are the steps of the fusing cycle, how each portion of this cycle is adjusted?

Fusing cycle is electrode touch the commutator hook, then press the commutator hook, holding the pressure and release

Please check graphic of the fusing cycle on welding setting photo

This cycle is related to four factors,

the electrode and commutator hook contacting face area,

pressure value, holding the pressure time, fusing voltage

You can get a best cycle by teamwork of this four factors,

High frequency 15KHz ensure the pure output DC current, while some fusing machine 2KHz, 4KHz not high frequency

The constant current can make sure fusing each segment without hesitate, so DC power supply is faster and save electricity

6. Is there any warning sign for bad fusing?

Yes, machine have this function

Please click below picture to view video