Anping tenglu metal wire mesh co.,ltd. |

|

Demister pad,oil filter mesh pad,mist eliminator for filter,Stainless steel ss mesh knitted wire demister pad

1. Screen defoaming machine features:

1, simple structure, light weight

2, big porosity and small pressure drop

3, large contact surface area, high defoaming efficiency

4, installation, operation, maintenance is convenient

5, long service life

2. demister Introduction:

silk screen defoaming device is a kind of efficient gas liquid

separation device. It has simple structure, big porosity and small

pressure drop, large contact surface area, high defoaming

efficiency, light weight, installation, operation, maintenance is

convenient. Screen also known as wire mesh mist eliminator

defoaming device is mainly used for separating diameter greater

than 3 ~ 5 mu mu m m droplets. When with the gas entrainment in a

certain speed rise, through the grid in the middle of the filter

wire mesh, due to the effect of inertia of the entrainment to rise,

makes the entrainment collisions with filaments and adhesion on the

surface of filaments. Filaments on the surface of the entrainment

further proliferation and entrainment itself gravity settling, the

entrainment form a larger droplets along the filaments mixed flow

to it. Because of filaments wettability, surface tension of liquid

and filaments capillary effect, make the droplets is bigger and

bigger, until its own gravity over rising gas buoyancy and

resultant force, the surface tension of liquid is separated to

fall. As long as chooses proper operating gas velocity conditions,

gas through the screen after defoaming device, the defoaming

efficiency can reach above 99%, can achieve the purpose of

completely removing entrainment.

3. demister USES:

in addition to the foam used in gas separation tower entrained droplets, to ensure mass transfer efficiency, reduce the value of material loss and improve the operation of the compressor after, more commonly defoaming device must be set up in the tower. Can effectively remove 3 -- 5 um droplets, tray if setting between defoaming machine, not only can ensure the mass transfer efficiency of tower tray, also can reduce the plate spacing. So the silk screen defoaming device is mainly used for gas and liquid separation. Also for the air filter is used for gas separation. In addition, the screen also can be used as instrument of buffer in instrument industry, in order to prevent interference of waves of electromagnetic shielding, etc.

Wire mesh demister specification :

| Specification List of Filter Mesh | |||||

| Model | Specification | Wire Diameter mm | Materials | Area/Weight m2/kg | Technical Notes |

| Standard | 40-100 Model 60-150 Model 140-40 Model 40-100 Model 40-100 Model 40-100 Model 40-100 Model | 0.1x0.4 0.1x0.4 0.1x0.4 0.27 0.1x0.4 0.25 0.2 | stainless steel wire stainless steel wire stainless steel wire gal. iron wire copper wire polyamide fiber PVC fiber | 1/0.5 " " 1/0.7

| 1, For 40-100 model: 40 holes in 100% width 2, Metal filter mesh can be processed into weaves type |

Features of knitted wire mesh

l Various materials. Different material knitted wire mesh can be used in various applications for different requirements.

l Solid structure. The interlocking structure of knitted wire mesh make the structure is solid, which will not loose when using.

l High efficiency. The knitted wire mesh can be used as demister pad for high filtering efficiency.

l Corrosion and rust resistance.

l Acid and alkali resistance.

l Temperature resistance.

l Wide range of applications.

Applications of knitted wire mesh

l Knitted wire mesh is widely used as demister pads for gas and liquid separators.

l Knitted wire mesh can be used for cleaning machines, kitchens and other components and parts.

l Compressed knitted wire mesh can be installed in the engines to decrease noise and reduce shocks.

l Knitted wire mesh can be used as shielding mesh for EMI/RFI shielding.

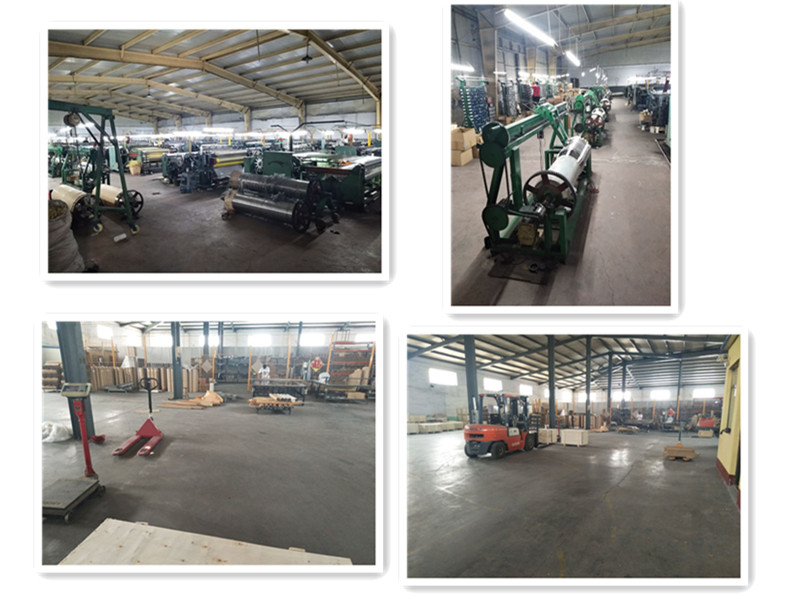

Anping tenglu metal wire mesh co.,ltd,is a manufacture and exporter of stainless steel wire mesh product.

We are located in wire mesh industrial base Anping city,Hebei province in China.

Our product range is as below,

Stainless steel woven wire mesh

Welded wire mesh

Crimped wire mesh

Hexagonal wire mesh

Knitted wire mesh

Wire mesh filter

Window screen

It have been 15 years that we manufacture and export wire mesh product,our professional responsible attitude and our strictly management technique ensure us standing in the leading position of wire mesh industry.We welcome your enquiry.

In order to make an offer,please provide us below wire mesh specification information.

Material

Wire diameter

Mesh size

Wire mesh length

Wire mesh width

If it is possible,please also provide us weight per roll that you required.