Shenzhen Jinyihe Technology Co., Ltd. |

|

Verified Suppliers

|

|

Customized Sheet Metal Fabrication Aluminum 5052 Sheet Prototype Service

Sheet Metal Fabrication Service

JYH Precision machining company provide high quality sheet metal cutting and bending service.

Metal parts for Prototypes to be used exclusively for development, testing, product evaluation, or quality control purposes.

Welcome to our premier sheet metal fabrication service. With a rich history spanning centuries, sheet metal fabrication remains a cornerstone of modern manufacturing. Our expertise in this field allows us to shape raw sheet metal into a wide array of precision-crafted components and products that cater to diverse industries and applications. From intricate designs to robust structures, our sheet metal fabrication service combines advanced techniques, skilled craftsmanship, and state-of-the-art technology to bring your visions to life. We take pride in our ability to transform flat sheets of various metals into three-dimensional wonders, meeting your specific requirements with unmatched precision.

Why use JYH’s for sheet metal fabrication?

Fast quoting & DFM feedback

| Quality & reliability |

Build and edit your quote within 30 minutes. Review your parts for manufacturability and assess the cost of different materials, processes and lead times for your project in real time.

| Dedicated JYH’s team to ensure your parts consistently meet your quality expectations. We also offer phone, email and chat support for any concerns or questions you may have. |

Tolerances for sheet metal fabrication

The table below summarizes the standard tolerances of the parts produced by JYH’s Manufacturing.

Feature

| Tolerance |

| Cutting feature | ± .00787’’ (0.2 mm) |

| Bend angle | ± 1.0° |

| Bend to edge | +/- 0.010’’ (0.254mm)

|

What is sheet metal fabrication?

Sheet metal fabrication is a manufacturing method that involves cutting and bending sheets of metal to form different shapes.

Sheet metal fabrication is more cost-effective than CNC machining when it comes to metal components with uniform wall thickness.

Available materials for sheet metal:

Below is a list of our standard available metals for sheet metal fabrication

Aluminum

|

Stainless steel

|

Mild steel

|

Copper

|

| 5052 | 304 | 1018 | C110 |

Available sheet metal fabrication processes

Name

| Description | Allowable sheet thickness |

| Laser cutting | This manufacturing process uses a high-power laser beam to cut a material sheet. | 1-6mm(depending on material) |

| Bending | This manufacturing process uses dies to produce a U-shape,V- shape or channel shape along a straight axis in ductile materials | 1-5mm (depending on material) |

Available surface finishes for sheet metal

Surface finishes are applied after machining and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts.

Picture of surface finish

|

Name

|

Description

|

|

Standard | This is our standard finish. Parts as delivered as cut and bent, no additional treatment applied. Sharp edges are broken and deburred for safe handling. |

| Bead Blasted | Parts are bead blasted with glass beads which results in a grainy texture. Sharp edges are broken and deburred for safe handling. |

| Brushed | Parts are manually brushed with grit #180 after cutting and bending. Sharp edges are broken and deburred for safe handling. Ideal to reduce the surface roughness of a part. |

| Brused + Anodized type II | Parts are dipped in an anodizing bath (type II) after manual brushing. Ideal for increasing the corrosion resistance of the part. Ideal for increasing the corrosion resistance of the part. |

| Powder coated | Powder coating layer is applied directly after fabrication. Sharp edges are broken and deburred for safe handling. |

| Black oxide | Parts are dipped in a black oxide bath after fabrication. Ideal to improve improve corrosion resistance and minimize light reflection in steel components. |

| Chromate conversion coating | Parts are dipped in an alodine bath directly after fabrication. Ideal to increase the corrosion resistance of the part while maintaining its conductive properties. |

Payment method

Quality assurance

Our unwavering commitment to product quality assurance in sheet metal fabrication is evident in every aspect of our process.

Utilizing advanced machinery for cutting, bending, welding, and finishing ensures accuracy and consistency in each product.

Our ISO 9001:2015, ISO 13485, and AS9100D certifications reinforce our commitment to maintaining the highest standards.

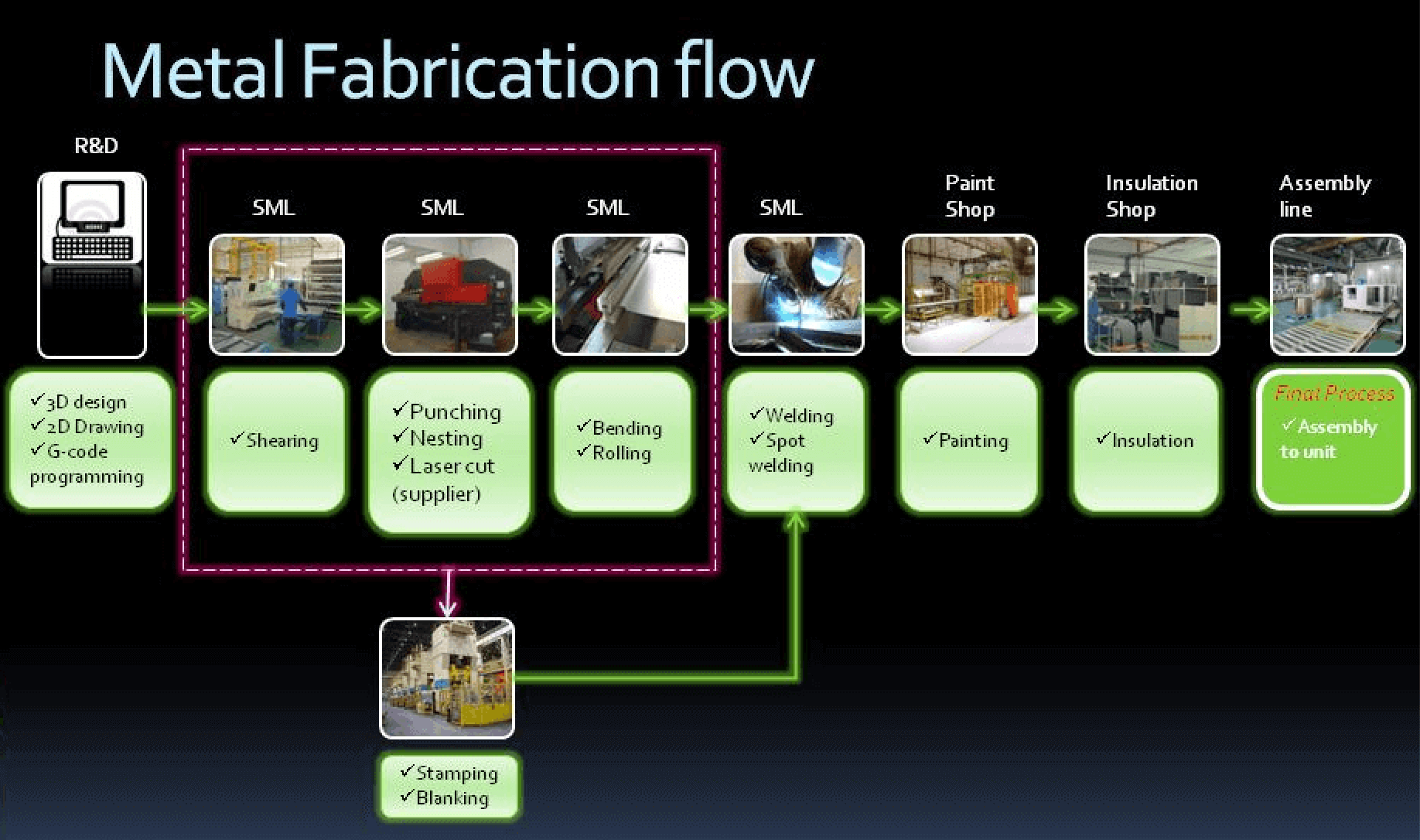

Our workshop

JYH is your best partner of Sheet Metal Cutting And Bending Aluminum 5052 Sheet Parts Fabrication!