Anping Blue Star Metal Wire Mesh Products Co., Ltd |

|

Custom Knitted Wire Mesh Demister Pad Mist Eliminator High Temperature Resistance

1.PTFE (f4) mesh demister is one of the best corrosion-resistant demister products. It can be used for a long time in any kind of chemical medium. PTFE mesh demister can resist hydrogen. Corrosion of fluoric acid, phosphoric acid, sulfuric acid, nitric acid, hydrochloric acid and various organic acids, organic solvents, strong oxidants and various other highly corrosive chemical media. The PTFE (f4) PTFE mesh demister can be used normally at temperatures between -150 and +250 °C.

Polytetrafluoroethylene (PTFE) characteristics

Appearance pure Baise high temperature resistance: use temperature

-200 ~ +250 ° C;

Low temperature resistance: 5% at -196 °C;

Corrosion resistance: resistant to strong acids, strong alkalis,

aqua regia and various organic solvents;

Insulation resistance: dielectric properties are independent of

temperature and frequency;

High lubrication: the lowest friction coefficient in solid

materials;

Non-adherent: no adhesion to any substance; strong self-lubricity:

friction coefficient of 0.04 in solid materials

Non-toxic: physiologically inert, implantable in the human body;

anti-aging can be used in the atmosphere for a long time.

Anti-pollution: low metal element blank value, lead content less

than 10-11 g/ml, uranium content less than 10-12 g/ml;

Ptfe wire mesh demister filter: PTFE (F4) grill material: 904L

PTFE knitted wire mesh can not crimped, so PTFE demister density is big, people usually use them together with Stainless steel 316/316L

2.PP plastic mesh pad is a kind of wire mesh knitted in particular type.

PP demister filter used for gas separation tower entrained droplets, to ensure that the mass transfer efficiency, reduce the loss of valuable materials and improving the tower after the operation of the compressor, more commonly in the top screen defoaming device Settings. Can effectively remove 3 - 5 um droplets, tray if setting between demister, not only can ensure the mass transfer efficiency of tray, also can reduce the plate spacing. So the screen defoaming machine is mainly used for gas liquid separation. Also for the air filter used for gas separation. In addition, the screen also can be used as instrument of buffer in instrument industry, in order to prevent the radio interference of electromagnetic shielding, etc.

The structure of PP screen foam remover is the same as that of stainless steel screen foam remover.while the difference is that Pp demister grid can be SS OR MATERAL

PP features:

1. Physical properties: PP is a non-toxic, odorless, tasteless opalescent polymer with a density of 0.9-0.91g/cm3. It is one of the lightest types of all plastics nowadays.It is particularly stable to the water, and the water absorption rate for 24 hours is only 0.01%, and the molecular weight is about 8-150,000.Good formability.However, due to the high shortening rate, thick - walled products are easy to depression.Products with good gloss, easy to color

The using temperture is usually under 100 degrees

2. Mechanical properties: PP has high crystallinity and regular structure, so it has excellent mechanical properties. Its strength and hardness are higher than HDPE.However, at a low temperature at room temperature, the impact strength is relatively poor due to the high degree of molecular structure regularity. When molecular weight increases, the impact strength also increases, but the molding function is poor

Production Process of PP Demister Filter/ Wire Mesh Demister / Plastic Mesh Pad

PP plasticmesh demister pad, remove droplet by impingement on the wire surface. The liquid collected on the filaments is then able to drain from the pad under gravity. They have a limited range of useful operation in which they provide almost complete removal of droplets down to about 3-5 microns. Turndown range of vapor rate is around 3:1. At excessively high vapor velocities, the liquid droplets that impinge on the wire surface are sheared off by the vapor and re-entrained before they are able to drain.

Benefits of PP Demister Filter/ Plastic Mesh Pad / Wire Mesh

Demister

* Easy to install in all process equipment

* Most cost-effective solution when equipment sizes are set by other requirements

* High efficiency with low pressure drop

* Emergency delivery available

Wire Size: 0.08mm - 0.30mm flat wire or round wire. Single-strand knitted, multi-strand knitted, metal & non-metal (various fibers) knitted wires may be pressed into various specification of corrugated wire as require.

other Material: SS304 304L 316 316L, Titanium, Nickel, Monel, Inconel etc.

SS304 -- Water solution ,nitric acid ,reduced crude

SS304L -- Petroleum fractions

SS316 -- Fatty acids ,reduced crude

SS316L -- Naphtenic acids ,and other corrosives

Monel -- For caustic soda,alkalis ,dilute acids

Incoloy 825 -- Acid,neutral and alkaline solutions like sulfuric

Incoloy 625 -- Phosphoric and fatty acids

Density: 128kg/m3 144kg/m3 168kg/m3,172kg/m3,190kg/m3, 220kg/m3 etc.

| Type | Specification |

| Standard type | 40-100 60-150 105-300 140-400 160-400 200-570 |

| High-efficiency type | 60-100 80-100 80-150 90-150 150-300 200-400 300-600 |

| High-penetration type | 20-100 30-150 70-400 100-600 170-560 |

| Damping type | 33-30 38-40 20-40 26-40 30-40 30-50 48-50 30-60 30-80 50-120 |

With the aid of latte technology, we manufacture precision designed PP Wire Mesh Demister or PP Demister Pad that are metal & PP wire knitted pads with maximum opening and contact surface. Available in various aperture sizes and dimensions, it's useful to trap liquid droplets escaping along with vapor that prevents high boiler products droplets carry-over into low boiler top condenser.

Wire diameter dw(mm) | Width tolerance (mm) | Density (kg/m3) | Surface area (m2/m3) | Free volume | ||

| Flat wire | Round wire | +10 -0 | 150 | 450 | 320 | 0.981 |

| 0.1*0.4 | 0.23 | |||||

Wire diameter dw(mm) | Width tolerance (mm) | Density (kg/m3) | Surface area (m2/m3) | Free volume | ||

| Flat wire | Round wire | +10 -0 | 182 | 626 | 484 | 0.977 |

| 0.1*0.3 | 0.19 | |||||

32 layers of knitted mesh for 100mm thickness

3)High Penetration of PP demister

Wire diameter dw(mm) | Width tolerance (mm) | Density (kg/m3) | Surface area (m2/m3) | Free volume | ||

| Flat wire | Round wire | +10 -0 | 98 | 313 | 217 | 0.9875 |

| 0.1*0.4 | 0.23 | |||||

28 layers of knitted mesh for 100mm thickness

Material: 302,304,304 L, 316,316 L, 317

Specifications are as follows:

Model: 20-40, 30-80, 40-120,50-120

Common diameter: 0.21mm

Form code: HR

Weight capacity: 168 Kg/m3

Specific surface area: 529.6 m2/m3

Porosity: 0.9788ε

Different performance between plastic material

| performance | Name abbreviation code unit project | PTFE | PCTEF | Polyvinylidene fluoride | Polyvinyl fluoride | PEP | PFA | Polypropylene | |

| PTFE | PCTEF | PVDF | ETFE | FEP | PFA | PP | |||

| F4 | F3 | F2 | F40 | F46 | PFA | PP | |||

special | Specific gravity | g/cm 3 | 2.1 to 2.2 | 2.1 to 2.2 | 1.76-1.78 | 1.73-1.75 | 2.1 to 2.2 | 2.1 to 2.2 | 0.83 ~ 0 .9 |

| Water absorption rate | % | 0.001-0.005 | ≤0.005 | 0.04 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | |

| Finished product shrinkage | % | 1 to 5 | 1 ~ 2.5 | 2.0 | 3.1-7.7 | 2 to 5 | 1 to 5 | 2 to 4 | |

| Thermal expansion coefficient | 10-5/K | 10 to 12 | 4.5 to 7.0 | 8.5 to 15.3 | 10.8 | 8.3 to 10.5 | 8 to 12 | 8 to 1 | |

| Embrittlement temperature T1 | °C | -180to -195 | -80 to -195 | -62 | -100 | -260 | -180 to -195 | -14 | |

| Continuous heat resistance T2 | °C | 260 | 120 to 190 | 150 | 150-182 | 204 | 260 | 80 | |

| * Recommended temperature T3 | °C | 180≤ | 180≤ | 100≤ | -65~+150 | 150≤ | 180≤ | 80≤ | |

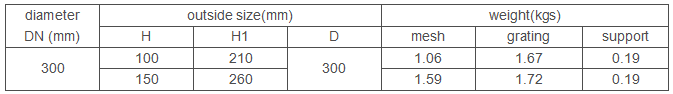

Technical parameter

Note:

u D stands for nominal diameter

u H stands for height or thickness of demister pads

u The weight is calculated according to stainless steel,stainless steel density is 7.93g/cm3,nickel density

is 8.90g/cm3,PP or PE density is 0.92g/cm3