TOBO STEEL GROUP CHINA |

|

Verified Suppliers

|

|

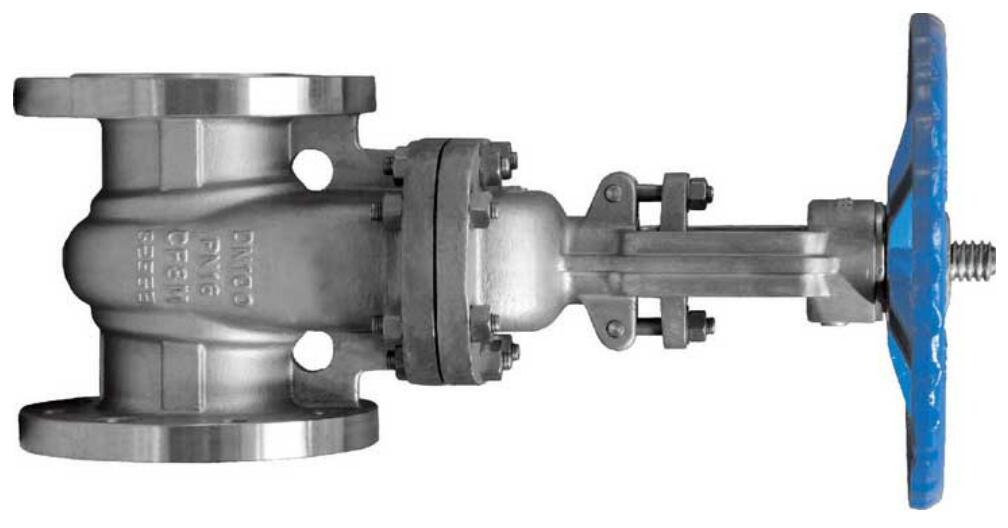

ANSI 416 STAINLESS STEEL ASME B16.10 DN200 150LBS DUCTILE IRON GATE VALVE

Gate valves are primarily designed to start or stop flow, and when a straight-line flow of fluid and minimum flow restriction are needed. In service, these valves generally are either fully open or fully closed.

The disk of a Gate valve is completely removed when the valve is fully open; the disk is fully drawn up into the valve Bonnet. This leaves an opening for flow through the valve at the same inside diameter as the pipesystem in which the valve is installed. A Gate valve can be used for a wide range of liquids and provides a tight seal when closed.

| Part No. | Part | Standard Specification | Options |

| 1 | Valve Body | ASTM A536, 65-45-12 | |

| 2 | Resilient Wedge Disc | ASTM A536, 65-45-12+SPDM | AISI 304, AISI 316, AISI 420,AISI 431 |

| 3 | Stem | Stainless Steel | AISI 304, AISI 316, AISI 416 |

| 4 | Bonnet Gasket | EPDM | NBR |

| 5 | Bonnet | ASTM A536, 65-45-12 | |

| 6 | Washer | Brass Hpb59-1 | |

| 7 | Yoke | ASTM A536, 65-45-12 | |

| 8 | Stem Bushing | Brass Hpb59-1 | |

| 9 | Gland | ASTM A536, 65-45-12 | |

| 10 | Stem Nut | Brass Hpb59-1 | Bronze ZQSn5-5-5 |

| 11 | Handwheel | ASTM A536, 65-45-12 | Pressed Steel |

| 12 | Washer | Brass Hpb59-1 | |

| 13 | Gland Nut | Carbon Steel Zinc Plated | AISI 304, AISI 316 |

| 14 | Stud | Carbon Steel Zinc Plated | AISI 304, AISI 316 |

| 15 | Flat Washer | Carbon Steel Zinc Plated | AISI 304, AISI 316 |

| 16 | Nut | Carbon Steel Zinc Plated | AISI 304, AISI 316 |

| 17 | O-Ring | NBR | EPDM |

Gate valves consists of three main parts.. body, bonnet, and trim. The body is generally connected to other equipment by means of flanged, screwed or welded connections. The bonnet, which containing the moving parts, is attached to the body, usually with bolts, to permit maintenance. The valve trim consists of the stem, the gate, the disc or wedge and the seat rings.

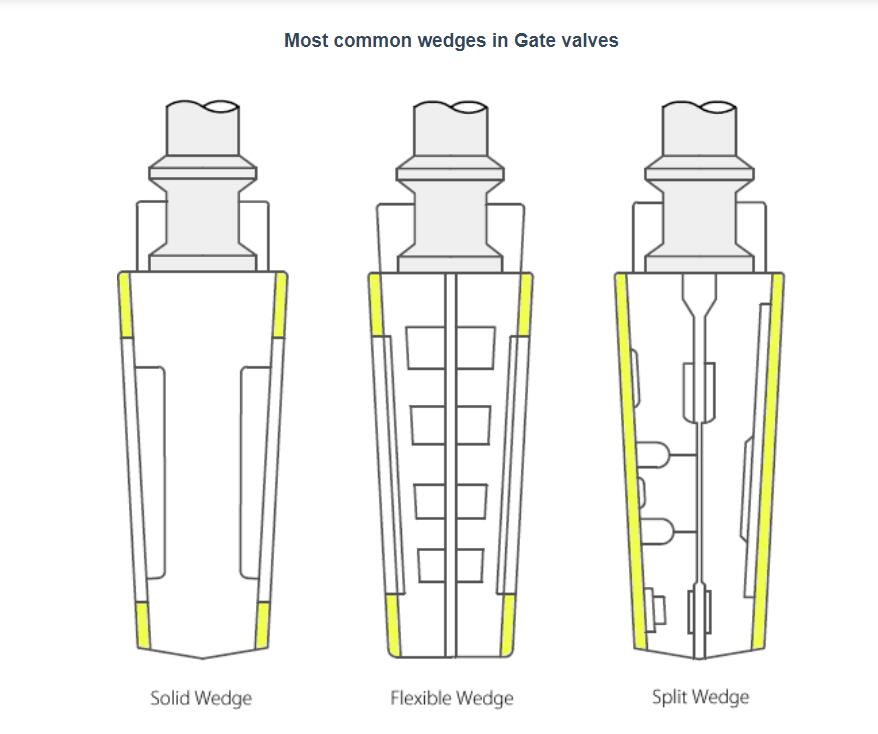

Gate valves are available with different disks or wedges. Ranging of the Gate valves is usually made by the type of wedge used.

The most common were..

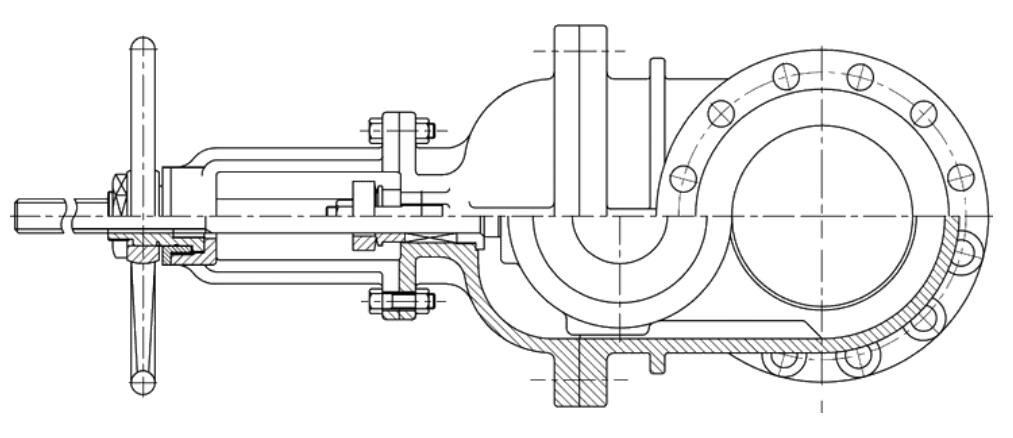

The stem, which connects the handwheel and disk with each other, is responsible for the proper positioning of the disk. Stems are usually forged, and connected to the disk by threaded or other techniques. To prevent leakage, in the area of the seal, a fine surface finish of the stem is necessary.

Gate valves are classified as either..

For a valve of the Rising Stem type, the stem will rise above the handwheel if the valve is opened. This happens, because the stem is threaded and mated with the bushing threads of a Yoke. A Yoke is an integral part from a Rising Stem valve and is mounted to the Bonnet.

For a valve of the non Rising Stem type, there is no upward stem movement if the valve is opened. The stem is threaded into the disk. As the handwheel on the stem is rotated, the disk travels up or down the stem on the threads while the stem remains vertically stationary.

In the main Menu "Valves" you will find links to detailed (large) drawings of both stem types.

Seats for Gate valves are either provided integral with the valve body or in a seat ring type of construction. Seat ring construction provides seats which are either threaded into position or are pressed into position and seal welded to the valve body. The latter form of construction is recommended for higher temperature service.

Integral seats provide a seat of the same material of construction as the valve body while the pressed-in or threaded-in seats permit variation. Rings with hard facings may be supplied for the application where they are required.

Advantages..

Disadvantages..

1st is screwed bonnet: This is the simplest design available and it is used for inexpensive valves.

2nd is bolted-bonnet: This is the most popular design and used in a large number of gate valves. This requires a gasket to seal the joint between the body and bonnet.

3rd is Welded-Bonnet: This is a popular design where disassembly is not required. They are lighter in weight than their bolted-bonnet counterparts.

4th one is Pressure-Seal Bonnet: This type is used extensively for high-pressure high-temperature applications. The higher the body cavity pressure, the greater the force on the gasket in a pressure -seal valve.