TOBO STEEL GROUP CHINA |

|

Verified Suppliers

|

|

A351 CF8 DN300 PN16 OS&YCAST STEAM VALVE FLANGED CAST STEEL FLANGED GLOBE VALVE

| DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ø P | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

| Ø P1 | 17 | 20 | 25 | 32 | 39 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

| L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 | 400 | 480 | 600 |

| H ( opened ) | 193 | 194 | 203 | 212 | 263 | 273 | 305 | 344 | 378 | 420 | 483 | 606 |

| H ( closed ) | 178 | 180 | 188 | 191 | 235 | 238 | 270 | 297 | 344 | 375 | 429 | 525 |

| Ø B | 100 | 100 | 120 | 120 | 160 | 160 | 180 | 200 | 250 | 250 | 320 | 360 |

| Weight ( Kg ) | 3,3 | 3,9 | 5 | 6,6 | 9,5 | 12 | 17,3 | 22,7 | 35,8 | 52,8 | 72,5 | 126 |

| Actuation | handwheel |

| Connection | for mounting between ANSI 150 and DIN PN 10/16 pipe flanges. |

| DN: | 15, 20, 25, 32, 40, 50, 65, 80, 100, 125, 150, 200 |

| PN: | 16 |

| Seal Material | SS AISI 420 |

| Tmax | -10°C/+300°C |

| Valve Type | Globe valve, rising stem |

Size: DN15-300mm

Pressure: Pressure: PN 10/16/25, ANSI150/300lb

Actuator: Manual

Type: Bolted Bonnet, OS&Y, straight/Y type/right angle

Standard: DIN, BS, API

Face to Face Dimension: DIN3202 or ANSI B16.10,

Flanged Dimension: DIN2501, ANSI B16.5

Industrial applications: Petroleum, Chemical, Paper Making,

Fertilizer, Coal Mining, water treatment and etc.

Carbon Steel ANSI 300 Flanged Globe Valve with metal seat. Designed and manufactured to BS 1873, Face to Face to ASME B16.10 with flanges to ASME B16.5, Tested by EN 12266-1. Stainless Steel reinforced graphite gasket and flexible graphite packing. 13CR reinforced seats and disc for greater durability and wear. Great for steam and high temperature applications. Globe Valves are also regularly used over gate valves or other manual control valves where the user wants to achieve a greater degree of flow control. As the shaft comes down it has a 'globe shape' on the bottom of it which slowly cuts down the flow before shutting off on the seat. All globe valves come with cast heat numbers to give quality assurance for testing and mil certificates.

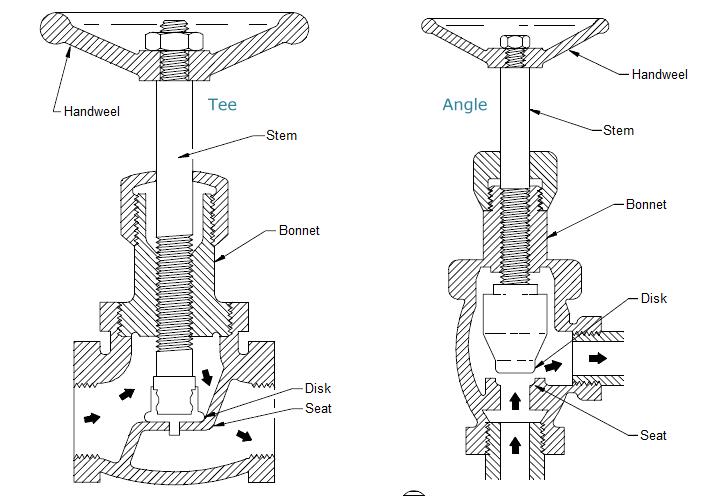

There are three primary body designs for Globe valves, namely..

Tee Pattern or Z-body

Angle Pattern

Wye Pattern or Y-body body

Disk.. The most common disk designs for Globe valves are.. ball disk,

composition disk and the plug disk. Ball disk design is used

primarily in low pressure and low temperature systems. It is

capable of throttling flow, but in principle it is applied to stop

and start flow.

Composition disk design uses a hard, non-metallic insert ring on

the disk, which ensures a tighter closure.

Plug disk design provides better throttling than ball or

composition designs. They are available in many different designs

and they are all long and tapered.

Seat.. Globe valve seats are either integrated or screwed in to the valve

body. Many Globe valves have backseats inside the Bonnet. Back

seats provides a seal between the stem and Bonnet and prevents

system pressure from building against the valve pakking, when the

valve is fully open. Back seats are often applied in Globe valves.

Stem.. Globe valves uses two methods for connecting the disk and the

stem.. the T-slot and the disk nut construction. In the T-slot

design, the disk slides over the stem, while in the disk nut

design, the disk is screwed into the stem.

The following are some of the typical applications of Globe valves..