TOBO STEEL GROUP CHINA |

|

Verified Suppliers

|

|

NPT BSPT PT BSP 1/2--4" CF8M stainless steel Y female thread

strainer

Specifications:

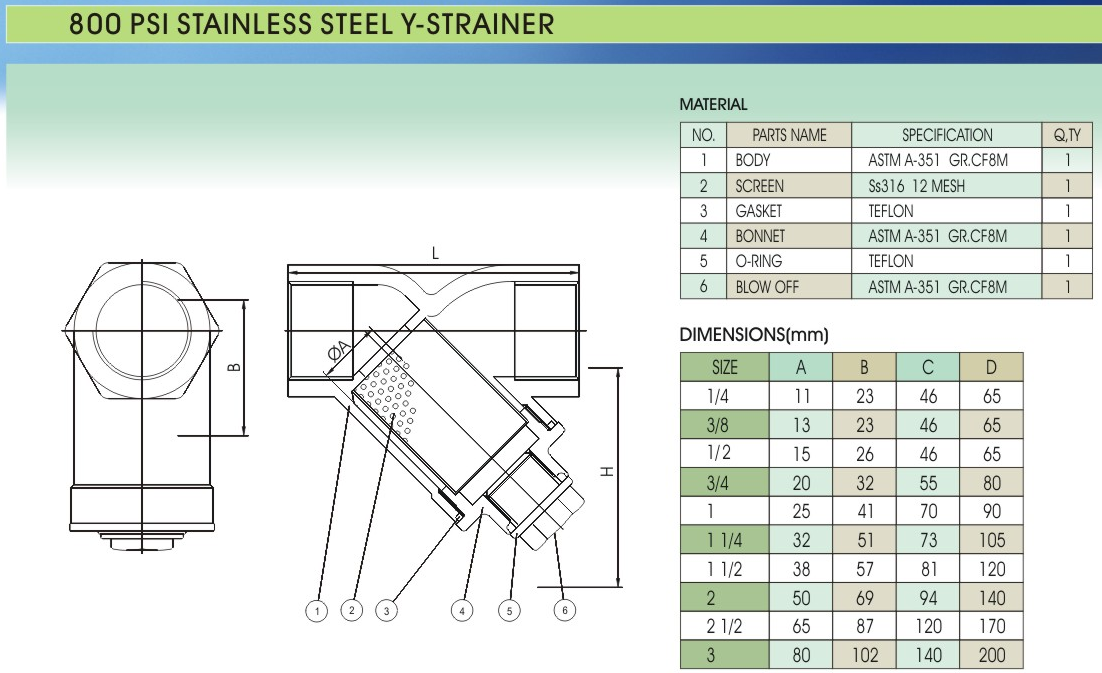

Y-strainer, 316SS Body & Screen, #12 mesh (1.4mm perforation), screwed ends BSP or NPT-rated 800 psi (56 Bar)- fitted with blowdown assembly comprising a special hex nipple (male 16UN X 1/2″ MALE NPT) and a 3-piece SS Ball Valve

Size 1/4” (DN8) → 3” (DN80)

* Options: WCB body, special fine mesh screens, NPT ends, flanged ends, 1-piece BV as blow-down valve

| Description | |||

| Product Name | Y type female thread strainer | ||

| Modle | GY11W-16P | ||

| Nominal diameter(DN)mm | 1/2-4" | ||

| Working pressure | 800WOG | ||

| Mesh | CF8M ,CF8,WCB | ||

| Design standard | DIN .APL.GB | ||

| Body | stainless steel | ||

| Gasket | PTFE/RPTFE | ||

| Applicable Media | Water,Oil,Gas and Corrosive Liquid | ||

| Temperature Applicable | (-30°C-280°C) | ||

| Material | SS316 .SS304 . | ||

| Threaded standard | NPT /BSPT /BSP /DIN | ||

| End connection | Threaded | ||

| Driven mode | Manual | ||

Y Strainer Design

As it's name implies, a Y strainer is shaped like a “Y” and is used

to filter, or strain, out particulates

from steam, gas or liquid. This mechanical straining process is

made possible via a filter element comprised

of mesh, perforated metal, or a wedge wire straining element. The

most common kind of straining element is

a wire mesh. Some also include “blow-off valves” that make the

cleaning process easier in applications with more

substantial dirt blowing. The strainer itself has a compact, Y

shaped design. The Y shape has better flow characteristics

than for example a T shaped strainer, because the fluid flows

through the filter with less change of direction.

Why Use a Y Strainer?

In general, Y strainers are critical anywhere clean fluids are

required. While clean fluids can help maximize the reliability and lifespan of any mechanical system, they're especially important

with solenoid valves. This is because solenoid valves are very sensitive to dirt and will only function properly with

clean liquids or air. If any solids enter the stream, it can

disrupt and even damage the entire system. Therefore, a Y strainer is a

great complimentary component. In addition to protecting the performance of solenoid valves, they also help safeguard other

types of mechanical equipment, including:

Pumps

Turbines

Spray nozzles

Heat exchangers

Condensers

Steam traps

Meters

A simple Y strainer can keep these components, which are some of

the most valuable and expensive parts of the pipeline, protected from the presences of pipe scale, rust,

sediment or any other kind of extraneous debris.

Y strainers are available in a myriad of designs (and connection

types) that can accommodate any industry or application.

Features

What is the difference between strainer and filter?

The key difference between strainers and filters are the size of the particles they remove. Strainers typically remove larger particles that are visible in a liquid or gas, while filters remove contaminants that are often so small, they cannot be seen with the naked eye.

What are the different types of strainers?

There are 4 common types of strainers used for oil and gas filtration. They are simplex strainers, y strainers, duplex strainers, and automatic strainers. Each different type of strainer has it's own advantages when being used.

Packing Details:

We choose suitable wood cases according to different valves and

arrange skilled workers to pack in case of bruise. Long term

cooperated forwarder will book space, clear customs and transport

for us without delay. There are three ways for transportation, by

sea, by air and by train. We will arrange transportation according

to customers' needs.

Delivery Details: According to the order, 7~60days