Qingtuo Metal Products (Qingdao)Co.,Ltd |

|

Verified Suppliers

|

|

Stainless Steel Hot Rolled Plate Stainless Steel Sheet 316L 6mm

316L is widely used in the chemical industry because of its excellent corrosion resistance. 316L is also a derivative steel of 18-8 austenitic stainless steel, with 2 ~ 3% Mo added. On the basis of 316L, many steel grades are also derived. For example, 316Ti is derived after adding a small amount of Ti, 316N is derived after adding a small amount of N, and 317L is derived by increasing the content of Ni and mo.

Product introduction:

| Commodity | Stainless Steel Hot Rolled Plate Stainless Steel Sheet 316l 6mm |

| Grade | 316L |

| Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

| Certification | SGS,BV,IQI,TUV,ISO,etc |

| Thickness | 3-100 mm |

| Width | 1219 mm |

| Length | 2438mm |

| Surface | NO.1 2D NO.3 |

| Standard | JIS,AISI,ASTM,GB,DIN |

| Delivery time | About 15 -30 days or based on the sales contract |

| MOQ | 1 Ton |

| Advantages | Hot rolling can greatly reduce energy consumption and costs. The metal plastic deformation is high during hot rolling, and the deformation resistance is low, which reduces the energy consumption of metal deformation. Hot rolling can improve the processing performance of metals and alloys. |

Brand Cross Reference Table:

| GB NEW BRAND | JIS | ASTM | UNS | KS | BS EN | AS |

| 022Cr17Ni12Mo2 | SUS316L | 316L | S31603 | STS316L | 1.4404 | 316L |

Gauge and Inch:

| Gauge | SS inch | SS mm | Mild Steel | Galvanized Steel |

| 3 | 0.25 | 6.35 | 0.2391 | |

| 4 | 0.2344 | 5.95376 | 0.2242 | |

| 5 | 0.2187 | 5.55498 | 0.2092 | |

| 6 | 0.2031 | 5.15874 | 0.1943 | |

| 7 | 0.1875 | 4.7625 | 0.1793 | |

| 8 | 0.165 | 4.191 | 0.1644 | 0.168 |

| 9 | 0.1562 | 3.96748 | 0.1495 | 0.1532 |

| 10 | 0.1406 | 3.57124 | 0.1345 | 0.1382 |

| 11 | 0.125 | 3.175 | 0.1196 | 0.1233 |

| 12 | 0.1094 | 2.77876 | 0.1046 | 0.1084 |

| 13 | 0.0937 | 2.37998 | 0.0897 | 0.0934 |

| 14 | 0.0781 | 1.98374 | 0.0747 | 0.0785 |

| 15 | 0.0703 | 1.78562 | 0.0673 | 0.071 |

| 16 | 0.0625 | 1.5875 | 0.0598 | 0.0635 |

| 17 | 0.0562 | 1.42748 | 0.0538 | 0.0575 |

| 18 | 0.05 | 1.27 | 0.0478 | 0.0516 |

| 19 | 0.0437 | 1.10998 | 0.0418 | 0.0456 |

| 20 | 0.0375 | 0.9525 | 0.0359 | 0.0396 |

| 21 | 0.0344 | 0.87376 | 0.0329 | 0.0366 |

| 22 | 0.0312 | 0.79248 | 0.0299 | 0.0336 |

| 23 | 0.0281 | 0.71374 | 0.0269 | 0.0306 |

| 24 | 0.025 | 0.635 | 0.0239 | 0.0276 |

| 25 | 0.0219 | 0.55626 | 0.0209 | 0.0247 |

Chemical Composition:

| Grade | C | Si | Mn | P | S | Ni | Cr | Mo | N |

| 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 12.00~15.00 | 16.00~18.00 | 2.00~3.00 |

Physical Property:

| Grade | Tensile Strength(Mpa) | Yield Strength(Mpa) | Elongation(%) | HBW | HRB | HV |

| 316L | ≥480 | ≥175 | ≥40 | ≤187 | ≤90 | ≤200 |

Difference:

The two most commonly used stainless steels 304316 (or 1.4308,1.4408 corresponding to German / European standards), the main difference between 316 and 304 in chemical composition is that :

316 contains Mo, and it is generally recognized that 316 has better corrosion resistance and is more corrosion resistant than 304 in high temperature environment. Therefore, in high temperature environment, engineers generally choose 316 parts. But the so-called thing is not absolute. In the concentrated sulfuric acid environment, do not use 316 at any high temperature. Otherwise, it will be big. People who study mechanics have all studied threads. I still remember a black solid lubricant that needs to be applied to prevent threads from biting at high temperature: molybdenum disulfide (MoS2), from which two conclusions can be drawn:

1: Mo is indeed a high-temperature resistant material (do you know what crucible gold is melted in? Molybdenum crucible!).

2: Molybdenum easily reacts with high valence sulfur ions to form sulfide. Therefore, no stainless steel is super invincible and corrosion resistant. In the final analysis, stainless steel is a steel with more impurities (but these impurities are more corrosion-resistant than steel). If it is steel, it can react with other substances.

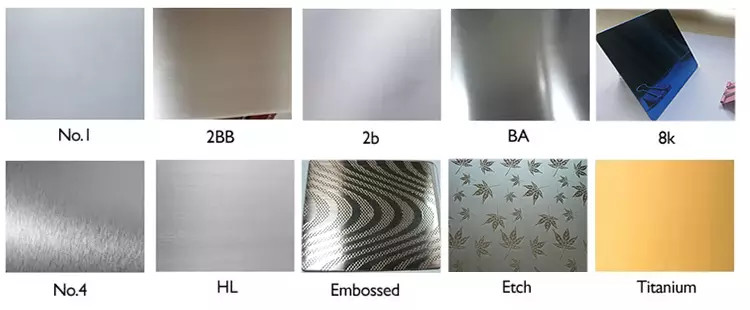

Surface Finish:

| Surface Finish | Definition | Application |

| 2B | Finished by heat treatment, pickling after cold rolling. Followed by skin pass line to be more brighter and smooth surface | General application Medical instruments, Tableware |

| BA | Bright heat treament after cold rolling | Kitchen utensil, kitchenware, architectural |

| 8K | A mirror-like reflective surface by polishing with finer abrasives over 800mesh | Construction, mirrors, plate sets, decoration elevators |

| HL | Finished by continuous linear polishing | Architectural purpose, Escalators, kitchenware, vehicles |

| NO.1 | Finished by hot rolling, annealing and picking, characterized by white pickled surface | Chemical industry Equipment, industrail tanks |

| NO.4 | Polishing with NO.150 to NO.180 mesh abrasives specified in JISR6001 | Kitchen utensils, Building Construction, Medical equipment |

Packing:

Stainless Steel Hot Rolled Plate Stainless Steel Sheet 316L 6mm Packing 2 types:

l Standard packing

l Fine packing

Factory and Machine Equipment:

We had our own factory to do slitting re-rolling and finish treatment machine,PVC and interleaving paper we will using with our machine for you,could protect stainless steel surface from damage or any scratches,

1. CNC Flame Cutting Machine

2. CNC Plasma Cutting Machine

3. CNC Laser Cutting Machine

4. Bending Machine

5. Shearing Machine

6. Punch Machine

7. Driving Machine

Stainless Steel Hot Rolled Plate Stainless Steel Sheet 316L 6mm Diaplay:

WHY CHOOSE US:

Q1: What is your terms of payment?

A: 30% T/T in advance, the balance 70% before delivery. We will

show you the photos of products and package before you pay the

balance.

Q2: what is the terms of delivery?

A: FOB, CIF, CFR,

Q3: What is the terms of packing?

A: generally, we pack our goods in bundles or coils with rods or

belts, we could also pack the goods as the customers' requirement.

Q4: What is your delivery time?

A: For stocks, we could transport the goods to loading port within

7 days after we received your deposit.

For production period, it usually takes about 15 days-30 days after

receiving the deposit.

Q5: Could you produce according to the samples?

A : Yes, we could customer-made by your samples or technique

drawings, we could build the mold and fixtures.

Q6: Could you provide the samples?

A: yes, we could provide the free samples on conditons it is

available in stocks, however, the the transportation fee is borne

by buyer.