Jiangsu XIANDAO Drying Technology Co., Ltd. |

|

Verified Suppliers

|

Tube Bundle Dryer

Applications:

1. The drying machine is suitable for drying the loose materials, for example: powder, particle and slice shape without big particles.

2. Application in chemical industry, food industry, feed industry and other industries, for example: starch factory, feed factory, meat processing factory, wine factory, beer factory and so on.

Technical parameters:

spec | speed of rotation (rpm) | main machine power (kw) | heat exchange area (m2) | drying capacity (evaporate kg of water/m2h) | overall dimension (L*W*H)(mm) | weight (T) |

| GZG50 | 5-8 | 5.5 | 50 | 4.7 | 8032×1712×2250 | 9.0 |

| GZG100 | 5-8 | 7.5 | 100 | 4.7 | 9100×1912×2470 | 14.0 |

| GZG150 | 5-8 | 11 | 150 | 4.7 | 8500×2212×2810 | 18.5 |

| GZG200 | 5-8 | 11 | 200 | 4.7 | 10000×2212×2810 | 20.0 |

| GZG250 | 5-8 | 15 | 250 | 4.7 | 10200×2212×2810 | 23.0 |

| GZG300 | 5-8 | 22 | 300 | 4.7 | 10784×2488×3383 | 26.0 |

| GZG350 | 5-8 | 30 | 350 | 4.7 | 12048×2488×3383 | 28.0 |

| GZG400 | 5-8 | 30 | 400 | 4.7 | 13048×2488×3383 | 30.0 |

| GZG500 | 5-8 | 45 | 500 | 4.7 | 11298×2982×3965 | 40.0 |

| GZG600 | 5-8 | 75 | 600 | 4.7 | 12298×2982×4165 | 45.0 |

| GZG700 | 5-8 | 75 | 700 | 4.7 | 13298×2982×4365 | 51.0 |

| GZG800~2000 | 5-8 | 75 | 700~2000 | 4.7 | / | / |

Product details:

| MOC: | SUS316/SUS304/ CARBON STEEL ,ETC | Heating Source: | Steam / Electrical / Natural Gas / Diesel / Etc |

| Temperature: | 100-350℃ | Drying area : | 3.3-200 m2 |

| Water Evaporation: | 10-1800kg/h | Power: | Customized |

General descriptions:

Features of GZG Series Tube Bundle Dryer :

GZG Series Tube Bundle Dryer (Pipe Bundle Dryer)is the indirect heated, contact type drying machine which can be both parallel flow and the counter-flow drying. It is extremely economic and practical. Among all kinds of the drying machines, it is the lowest in its power consumption and heat consumption. Evaporating one kg of water only consumes 1.5 to 2kg steam, only 50% of the fluidizing dryer’s consumption. Drying one ton fermented grass powder consumes 15kW/h, only 25% compare to fluid- bed. Both the electric power consumption and the steam consumption reach the advanced level of the same kind products. The materials with high water content can be dried, the drying flexibility is wide. The drying time can be adjusted according to the materials’ property and moisture requirement. It can be continuous operation of high automation, or intermittent operation for special technical process. The machine has less accessories, compact technical process and occupies a small area, besides, it’s easy to install.

Description of equipment structure and material

General description on safety

In case of malfunction or failure of the equipment, necessary protective measures shall be taken to ensure that the equipment and products remain in a safe state. Provide the following facilities to ensure the safety of personnel, products and equipment:

A) Proper fault detection and alarm notification

- Pressure transmitter for operating gas : the equipment cannot start or the atomizer cannot spray when the gas pressure is too low. (optional)

- Pressure transmitter in the container: when the positive pressure in the container exceeds the set value, the inlet and outlet valves will automatically close to ensure the safety of the operator and the room. (optional)

- Pressure transmitters for each airbag of the equipment (limited to airbag sealing device if necessary): when the air pressure of each airbag seal of the equipment is too low or leakage occurs, the equipment will not be able to start or alarm or stop. (optional)

- Current and voltage transmitter: when the current and voltage are too high or too low during the operation of the equipment, the operator will be notified to stop the machine for detection or automatic shutdown. (optional)

B) Warning sign of host/main set

- warnings for all hot/main set surfaces.

- the warning signs are shown below:

- all rotating parts shall be properly sealed.

C) The button of emergency stop shall be located in an area accessible to the operator

- The button for emergency stop is set on the operation screen of the man-machine interface, which is easy to operate.

D) Noise 1m away from the device is below 75 db.

- After the noise source is isolated, the noise of the device can be less than 75db.

E) Set a good grounding device at each isolation place of the equipment ,so as to better eliminate the static electricity generated when the equipment works.

F) Power failure and recovery

- In case of power failure, in order to protect the operator, the equipment itself and the product, the equipment is in a stop state.

- It is necessary that human intervention should be required to re-start the power, and the equipment cannot run automatically as required by GMP when the power is resupplied.

Features of material

| normal material light industry | water contents before the entering the machine | water contents of dry product | drying strength evaporation 2 kgH2O/m h | energy consumption (kj/evaporate kg of water) |

| straw | 55% | 3-5% | 2.5-3 |

3500-3800 (kj/evaporate kg of water) (840-910 <LCal/ evaporator kg of water>) <amount to about 1.45- 1.50 kg of standard saturated steam> |

| corn fibre | 60% | 10-12% | 4.8 | |

| fermented grass power | 45% | 12-13% | 4.7 | |

| wooden piece and wooden chip | 20% | 2-3% | 4.3 | |

| potato fibre | 65% | 10-12% | 4.8 | |

| distiller's grains for beer or spirit | 65 % | 10-12% | 4.9 | |

| feed carrier | 16% | 6-8% | 4.2 | |

| rape seed | 60% | 5-7% | 4.5 | |

| pig blood fermented power | 35% | 10% | 4.4 | |

| bone power | 40% | 10% | 4.6 |

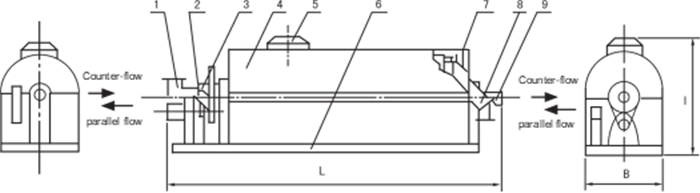

Flowchart:

1. material inlet

2. driving device

3. steam connector

4. exterior shell

5. exhaust opening

6. foundation

7. interior element of pipe bungle

8. material outlet

9. steam outlet connector