Changzhou Yibu Drying Equipment Co., Ltd |

|

Verified Suppliers

|

|

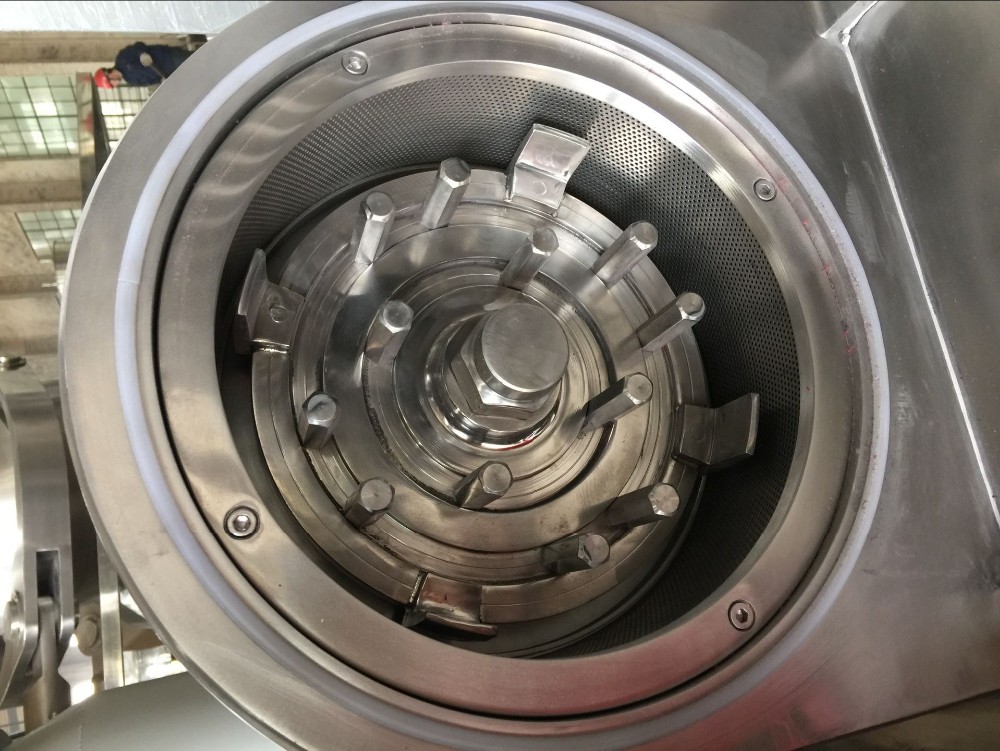

This machine is mainly used for chemical industry, medicine (traditional Chinese medicine), food, flavor, resin powder, powder coating and other weak electricity materials and high temperature resistanct materials. It is a new generation of crushing equipment integrating crushing and dust removing.

Principle:

The machine adopts the wind-wheel high speed rotating cutter and fixed cutter for impacting, shearing and grinding. In addition to having good crushing effect, the machine can produce powerful air flow inside the cavity during the crushing to discharge the heat and finished products from the crushing chamber through the mesh screen. The granule size can be determined by changing mesh screens of different bore diameters. The machine makes use of the high speed relative movement between the moveable and fixed gear plates, so as to make the materials crushed under the impact and friction of gear plates, so as to make the materials crushed under the impact and friction of gear, as well as impacts between materials. The materials after crushing will automatically enter the collection bag under the action of rotary centrifugal force. The dust will be recovered through the dust suction box after going through the bag filter.

Feature:

1. The machine is elaborately made of high quality austenitic stainless steel. The crushing cavity is flat and smooth without powder accumulation.

2. There is no dust during production. The machine has such features as simple and solid structure, stable running, easy cleanning and good crushing effect.

3. The crushed materials can be discharged directly from the machine grinding cavity. The granule size can be obtained by changing mesh screens of different bore diameters, and it is convenient to change the mesh screen.

4. The machine has no dead corner of sanitation and is easy to clean and maintain, meeting FMP requirements.

1. This machine use the relatively high speed of and use activities

chain-ring between fixed tooth plate, so that was crushed by the

chain-ring impact, friction and material collide with each other

and get crushed.

2. Crushed material by the centrifugal force, automatically enter

the trap bag, dust from the vacuum tank was recovered by filtration

bag.

3. The machine adopts high-quality AISI304 or AISI316L stainless

steel, the production process no dust, and can improve the

utilization of materials, reduce business costs. Replacement of

different particle size is determined by the number of screens.

| Model | 20B | 30B | 40B |

| Capacity(kg/h) | 20-150 | 30-300 | 40-800 |

| Main shaft speed(r/min) | 5600 | 4500 | 3800 |

| Feeding materials dia(mm) | 6 | 10 | 12 |

| Crushing mesh(mesh) | 12-120 | 12-120 | 12-120 |

| Power(kw) | 4 | 5.5 | 7.5 |

| Fan power(kw) | 1.5 | 1.5 | 2.2 |

| Size(mm) | 1100×600 ×1550 | 1250×750 ×1650 | 1500×800 ×1680 |

| Weight(kg) | 290 | 380 | 560 |

4. Inside the enclosure (crushing groove) all alveolar by precision

machined so as to achieve a smooth surface, easy to clean and

change the ordinary mill rough wall, easy to accumulate dust, the

phenomenon is difficult to clean, the food, pharmaceutical,

chemical and other production line with GMP requirements .

5. The machine structure is simple, robust, smooth operation, the

crushed material quickly and evenly, with good results.

The machine(set) is extensively used in chemical, pharmaceutical, food and pesticide industries for grinding dry brittle materials.

Note: the outputs in list are only for reference, due to the difference of material and required size.

Different design of component of grinding:

Type One:

Type two: