Changzhou Yibu Drying Equipment Co., Ltd |

|

Verified Suppliers

|

|

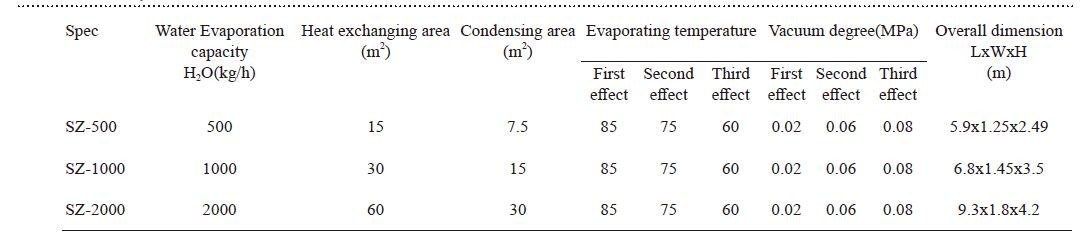

Falling film evaporator have Single effect falling film evaporator, double effect falling film evaporator, three effect falling film evaporaot. they are widely used with high efficient heat exchanger ratio, short heating time etc.

Evaporation temperature usually focus on 46-50 degree, especially used for active fermentation liquid, heat sensitive food evaporation, also suit for kinds of water solution low temperature continuous evaporation concentration ,such as glocuse,xylose,starch sugar,oligose,fresh milk and maltodextrin. falling film evaporator is widely used in the industry of food, chemical,pharmacy,biology engineering,environmental engineering and waste water recycle etc.

Processing Flow

The material which entered into the balance tank will pumped to the pipeline of the preheater though flow meter and right angle valve, after heating to evaporating temperature, the material will flow to the distributor of 1st Effect Evaporator and distribute into every evaporating pipeline evenly, then flow down along the wall with membrane state, the material start to evaporate by steam which comes from steam manifold and heater jacket. this is the first evaporation

The secondary steam produced run to bottom of the chamber together with material, enter into 1st effect separator at tangent direction, then secondary steam and material separated when rotating, raw material enter into separator at top the 2nd effect evaporator by pump though discharge tube. Finishing the second evaporation concentration as the same way of first evaporation.

And then, send to the top of distributor of the 3rd Effect Evaporator for concentrating as the same method. Finally, the material will reach the required concentration and discharged by Outlet pump though bottom of separator, then do next process by discharge pump.

Saturation vapor enter into steam distribution cylinder from main branch( about 0.6-0.8kg per cm2 ),and then enter into 1st,2nd,3rd evaporator, condenser and relative four preheaters, for supply heat energy to the material. The secondary steam which separated from separator will be inhaled to condenser for cooling, the condensate will be pumped out by condensate pump as pre-treatment using or use in boiler.

This concentrator is suitable for concentrating the liquid material such as Chinese herbal extract ,western medicine ,glucose, starch , gourmet , foodstuffs ,milk product and chemical product,especially suitable for heat sensitive material for their vacuum concentration under the low temperature .

◆ This equipment adopts the principle of tubular circulation

out-heating working principle to keep the short heating time of

materials ,rapid evaporation speed ,large concentration ratio ,so

as to keep the raw -effect of materials effectively .

◆ Steam energy will be well saved 70% than single-effect evaporator

. The materials are evaporated&concentrated under sealed state

which are clean and comfortable .Besides,it is equipped with

special foam-removing device to prevent the material running

phenomenon .

◆ All the parts contact with material are made of stainless steel

and be polished . The equipment has the properties of good

corrosion-proof,easy to clean in accordance with requirements of

pharmacy ,food hygiene. It can be matched with PC control system .

It is easy to operate with stable.