GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

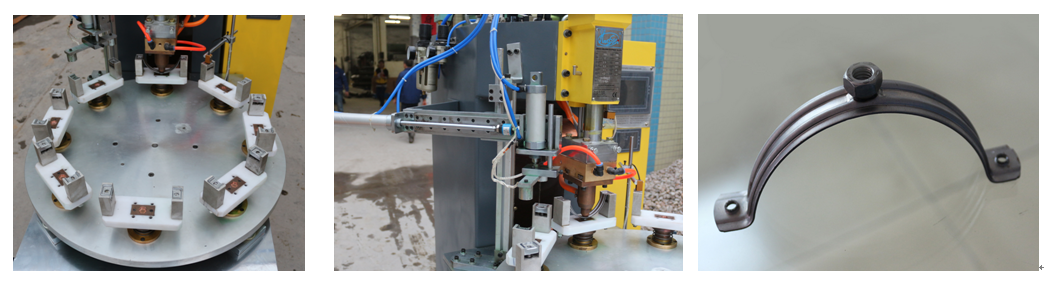

HWASHI Pipe Clamp Automatic Welding Machine with Rotary Table

DESCRIPTION

The zinc plated single scree clamp welding machine is composed of automatic welding machine, automatic rotatary table and automatic unloading device. The operator only needs to change the fixtures (welding moulds) then the machine can achieve welding of products with different sizes.

After welding the first work piece, the rotary table will rotate, then the second work piece will be moved to the welding position, cycle process will continue. Meanwhile, the welded work piece will be discharged automatically one by one and the operator could keep putting new work piece onto the certain position.

The operator only needs to put the work piece onto the rotary device, 8 work pieces at most for one time. Then start “welding”, the main welding body will conduct welding.

SPECIFICATION

| Model | WL-MF-100K |

| Input Voltage | 380V three-phase |

| Input Current | 150A |

| Output Voltage | DC11.6V |

| Max Short Circuit Current | 32000A |

| Welding Models | 30 types |

| Rotary Table Diameter | 600mm |

| Rotary Table Material Positions | 4 positions |

| Rotary Table Rotating Speed | 0.5m/sec |

| Welding Cylinder | ¢80X2x80mm |

| Lower Mould Cylinder | ¢160x50mm |

| Machine Dimension | 900x1300x1700mm |

| Weight | Around 800kg |

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2.After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

3. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

4.Prompt Response to Customers: Your satisfaction is the goal we pursue.

5.Quick Delivery: Our company provides just-in-time delivery.

APPLICATION

Suitable for welding galvanized steel pipe clamp and zinc plated product.

MATERIAL CONFIGURATION

1. Adopt integrated circuit from Motorola of U.S. and PLC from Japan SIEMENS with quick response and stable performance.

2. Adopt Japan Panasonic intelligent touch screen control system which is installed with automatic bug alarm system. Clear interface, easy operation, and stable performance.

3. Adopt Taiwan TECO servo motor with powerful strength, high precision and stable control.

4. Adopt silicon controlled from IXYS of United Stated with high precision and long service life.

5. The transformer adopts Japan high purity silicon steel sheet with good magnetic and electricity conductivity. Less power consumption, more powerful and stable capacity.

6. Strictly comply with CE security standard to design the machine. Lower the accident rate.

7. Adopt self-developed intelligent microcomputer welding control system to control the compensation for the fluctuation of circuit built-in voltage in order to ensure the fluctuation of voltage is within ±15%. Prompt current compensation to ensure the stable welding current of power source.

8. Adopt South Korea SANWO pneumatic components with stable performance.