GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

HWASHI TECHNOLOGY Inc.

Website: www.hwashi.com

Thank you & Welcome your Inquiry!

Detailed Description

This condenser welding special machine is customized for welding

condenser as well as wire mesh. According to the product

specification provided by your company, and in order to increase

efficiency and production rate, the machine is designed as two

feeding fixture system, automatic wire feeding system, automatic

mobile system, automatic welding system, and cooling system.

The welding process is as follows,

1) When starting working, the welding fixture will firstly enter

into the automatic wire feeding area to complete the bottom layer

automatic wire feeding;

2) Then the fixture will move back to the manual loading area, the

operator needs to put the S-shaped copper tube onto the bottom

layer wire;

3) Afterwards, the fixture will move to the automatic wire feeding

area automatically to complete the upper layer automatic wire

feeding;

4) Then, the fixture will move forward to enter into welding area

to complete welding process.

5) After welding, the fixture will move back to the unloading area.

The fixture will be loosening through vibration.

6) At last, the fixture will return to the loading area for the

operator to take out the work piece and start the next welding

process.

In order to improve the efficiency, the machine is designed with

both sides feeding rack. The welding process for both sides is the

same which will take turn to work.

Features

1. Main Body:Because of the dense and horizontal wire rod, the integrated

reinforced gantry type of main body is designed. Adopt the vertical

stress main body. This machine is made of good quality of thicken

steel plate to ensure the intensity and stability of the main body.

The machine is equipped with slide guide to provide stress

supporting point and working platform for other actions. In order

to put two sets of welding fixtures on the machine, the effective

welding width is 1300mm while the welding length is 1000mm.

2. Power Source: Adopt medium frequency inverter welding source. Duty cycle rate

reaches 50%. The three-phase power supply is under rectifying

through a special inverter and converted to 1000Hz AC voltage and

then be transmitted to a medium frequency transformer to be

rectified so as to provide DC welding current. Compare with general

AC pulse power supply, this kind of power source could be fast and

precisely adjusted. Small impact to the power grid and lower

requirement for the power grid compare with the single-phase welder

of the same capacity.

3. Row Welding Structure: 6 sets of welding electrodes are installed on the beam and

equipped with slide guide that could move horizontally. It is

convenient to adjust the distance of welding spot so it is suitable

for welding the work pieces with different pinch. The welding

program of row welding electrode is flexible and various kinds of

welding programs are available. So you could choose to weld from

the middle to the sides or from the sides to the middle or single

welding. Truly achieve the stable, reliable and good consistency of

welding effect.

4. Cooling System: Resistance welder will generate lots of heat during the process of

welding. The source of heat may be from: the welding of electrode

and work piece or the working of components like silicon controlled

and welding transformer. In order to protect the working life of

components and control the softening temperature of welding

electrode to ensure the reliability of welding, it is designed to

adopt the cooling water cycle to take away the heat. The air-cooled

type of cooling water is adopted. Through the refrigerating system

of cooling-water machine, the temperature of water is forced to

cool down to the preset temperature. The purpose of cooling water

cycle is achieved through the water pump of cooling-water machine

and water storage box.

Applicable Area

Continuous welding condenser or wire mesh products.

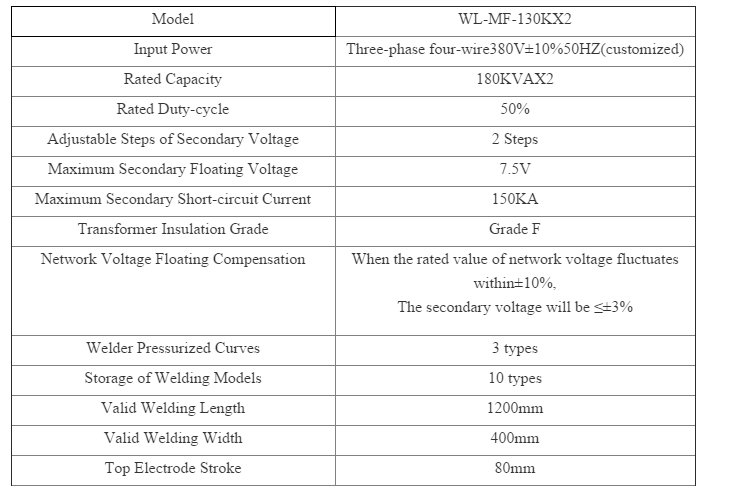

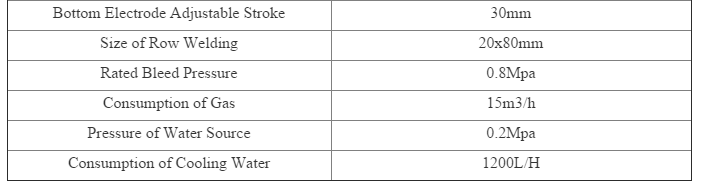

Technical Parameters

High Reliability Refrigerating Condenser Welding Machine

Company Profile

Guangdong Hwashi Technology Inc. was established in 2001. The

headquater is located iin Hwashi technology industrial area,huiyang

huizhou city. It is a high-tech enterprise specailizing in

developing ,manufacturing andselling of resistance welding machine,

automatic welding machine and industrial robot.

Hwashi has moe than 20 technicians who are the experts in R&D

work of electrical engineering, mechanical engineering, welding

technology, quality inspection,ect. So that Hwashi has the

comprehensive R&D capability of developing new product,

engineering design and mold design, product inspection and test,

on-site technical support,ect.

Qualificaton Honors

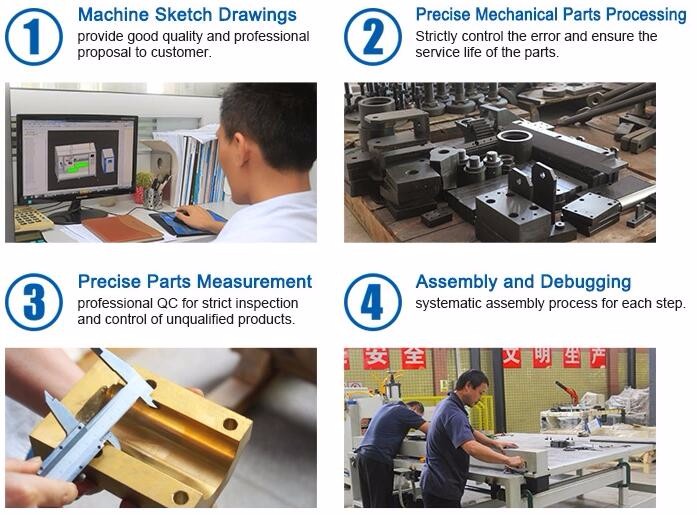

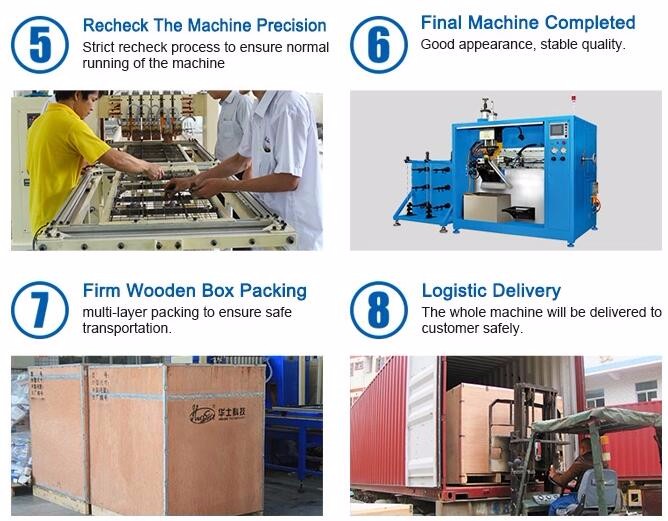

Producing Process