GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

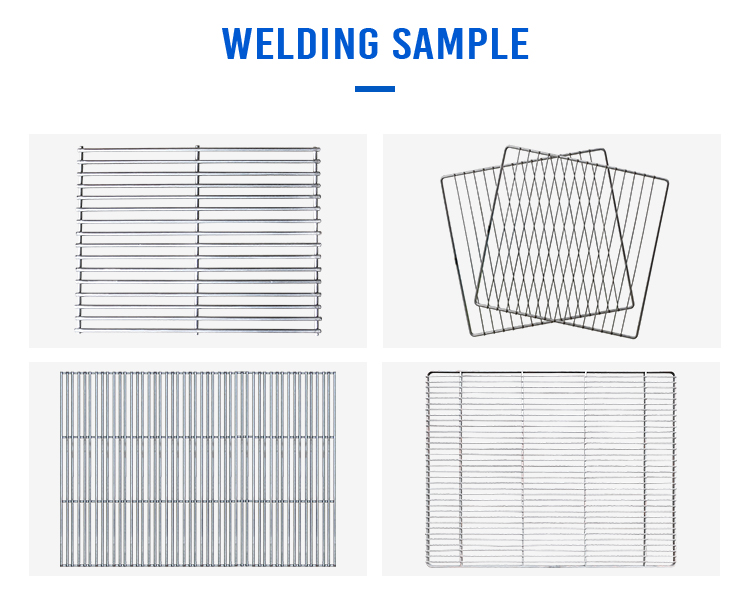

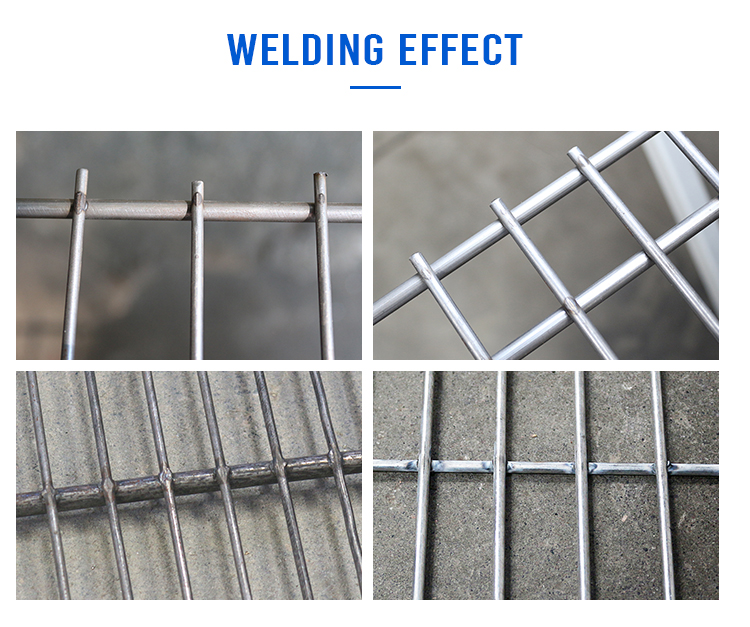

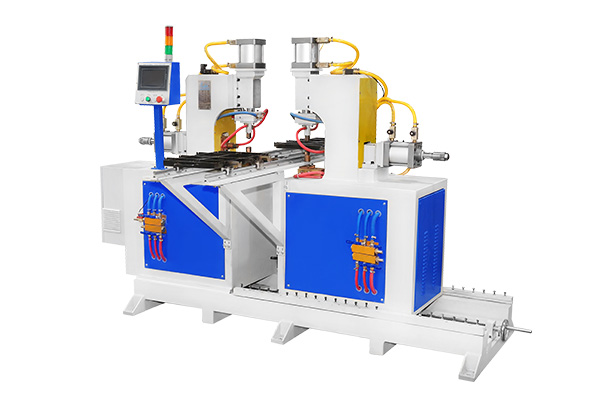

HWASHI Automatic Electric-Resistance Welded Wire Mesh Panel Cage

Welding Making Machine Line for Welded Wire Mesh

Power Supply:

Choose between a robust three-phase MF DC power supply system or a

versatile two-phase AC power supply system. Opt for either a single

set for standard operations or double the efficiency with two sets

for increased productivity.

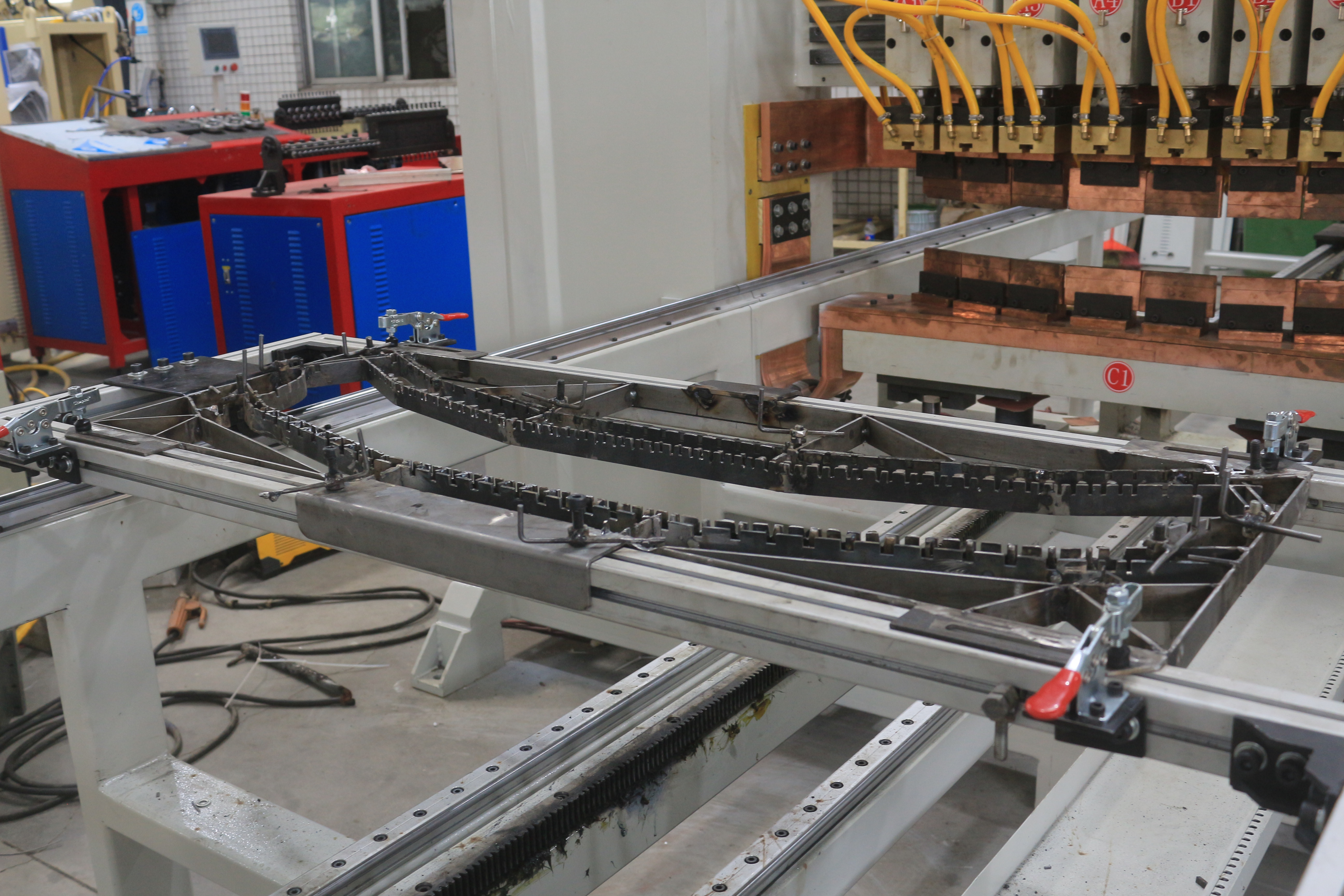

Feeder:

Select from a sophisticated double-layer automatic feeder featuring

precise cycle working and accurate stepping position control via

servo motor, or opt for the flexibility of a manual feeder to

tailor feeding operations according to specific project

requirements.

Unloading Device:

Enhance workflow efficiency by opting for an automatic unloading

device, designed to seamlessly remove finished wire mesh products

from the machine. Alternatively, maintain manual control over

unloading operations with a manual unloading device for greater

adaptability.

Automatic Bending Device:

Elevate production capabilities with the integration of an

automatic bending device, enabling the machine to effortlessly

shape wire mesh according to desired specifications. This feature

enhances customization possibilities and reduces manual labor.

Automatic Straightening and Cutting Machine:

Streamline production processes and ensure precision with an

automatic straightening and cutting machine. This component

automates the straightening and cutting of wire, optimizing

efficiency and minimizing material waste for high-quality wire mesh

production.

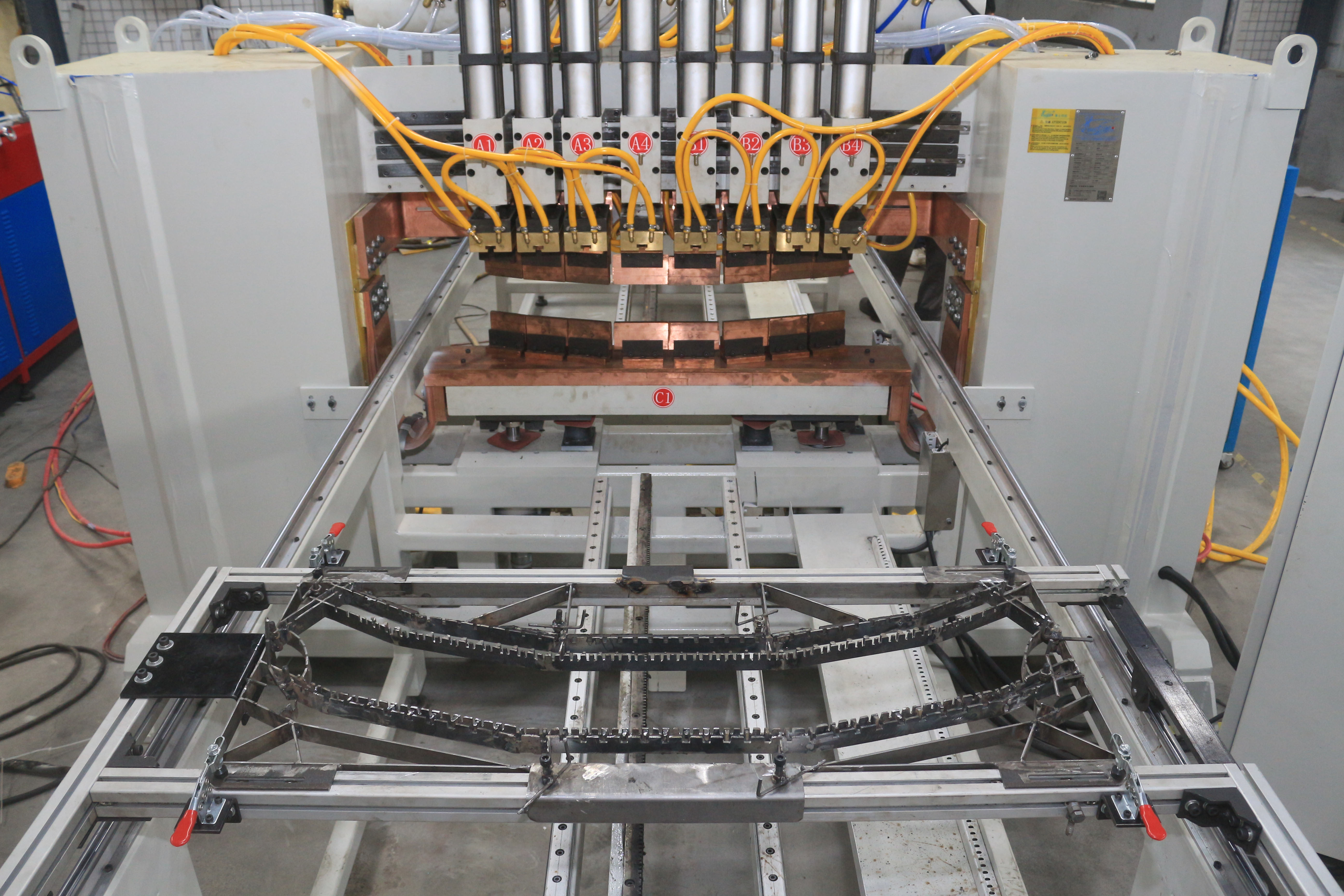

Our Gantry Row welding machine is expertly crafted to facilitate

the rapid production of wire mesh, particularly suited for

applications requiring a higher concentration of vertical (y) wires

compared to horizontal (x) wires. With a robust three-phase power

source, combined with advanced welding technology featuring one-way

double-layer automatic stepping feeding with 12 welding heads, this

machine delivers exceptional performance. Its adjustable effective

welding width and length further enhance versatility, making it a

valuable asset for diverse manufacturing needs.

|  |

Intelligent welding control system | Welding Heads and Fixtures |

|  |

Automatic Wire Filling System | Automatic Double-layer Feeder |

Production Line Machines

|  |

Wire Flattening and Cutting Machine | High Speed Wire Straightening and Cutting Machine |

|  |

Wire Frame Bending Machine | Wire Frame Butt Welding Machine |

|  |

Wire Frame Double T-Butt Machine | Wire Edge Trimming Machine |

|  |

2D Wire Handle Bending Machine | 3D Wire Bending Machine |