GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

HWASHI Automatic Spot Welding of Stiffeners on Shelves , Automatic

Resistance Welding Machine

This Door Panel Multi Head Spot Welding Machine adopts multiple

welding heads with automatic welding. You can choose multi head

welding at the same time or each head welding in turns. It is

suitable for door panel or sheet metal multi spot welding.

The effective welding width is 1000mm to 2000mm while the effective

welding length is 300mm (customized). The material thickness is

ranging from 0.4mm to 1.5mm.

Working Process

* Manually put the workpiece onto the table;

* Press the start button, then the machine will conduct welding

automatically for one line of spots;

* After welding one line, then manually move the product to another

line. Then press the start button again.

* Cycle working

Advantages

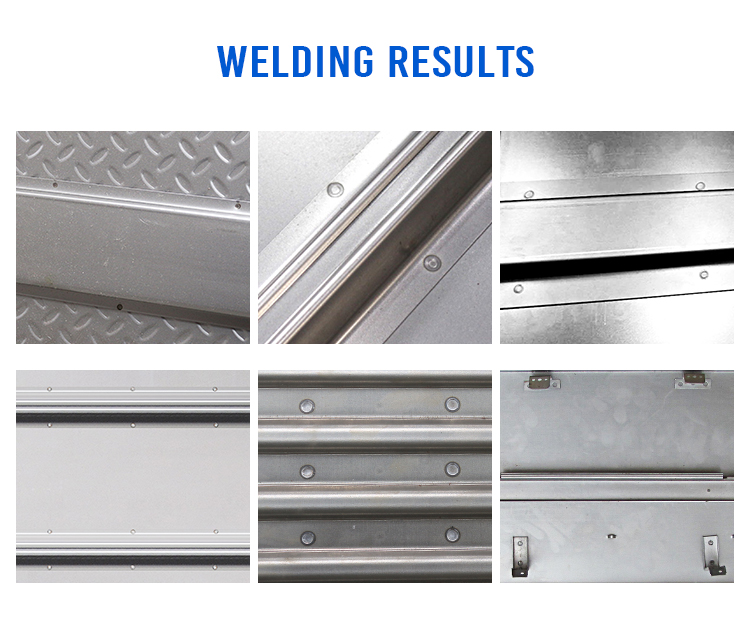

* Refined welding

* No need for special equipment

* Multi head welding at the same time

* Maximally easy working area access

* Production flexibility

* Reduced labor costs

Product Features

1. Flexible using: you can adjust the welding head distance as per

your drawing request. Only need to loose the bolts on the cylinder

then you can move the cylinder from left to right.

2. Reduces set-up time: Unlike conventional stationary spot

welders, this system significantly reduces the need for ancillary

work such as electrode adjustment and workbench set-up,

contributing to a reduction in overall welding man-hours.

3. Easy to set welding parameters:The welding conditions can be

easily set using the touch panel system.You can save the different

welding parameters for different material and thickness. So you can

recall the welding program easily.

4. Comfortable working position: There is no need to hold the

workpiece during welding; it can simply be placed on the electrode.

Pressurization is also automatic, greatly reducing the physical

burden on the operator. The amount of work that can be done per

unit time is also dramatically increased.

Specification

S.N | Items | WL-SF-MF160K | WL-SF-MF120K | WL-SF-MF100K |

1 | Input Voltage | 380V,3-Phase | 380V,3-Phase | 380V,3-Phase |

2 | Input Power | 160KVA | 120KVA | 100KVA |

3 | Max.Welding Current | 32000A | 30000A | 28000A |

4 | Max. Electrode Force | 2.2KN | 2.2KN | 2.2KN |

5 | Welding Capacity | 3+3mm | 2+2mm | 1+1mm |

6 | Welding Schedule | 32 Kinds | ||

7 | Effective Size Of Welding Platform | 2000x300mm (customized) | ||

8 | Welding Head Numbers | 10 to 20 (as per your drawings) | ||

9 | Distance Between Electrodes | 100-300mm | ||