GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

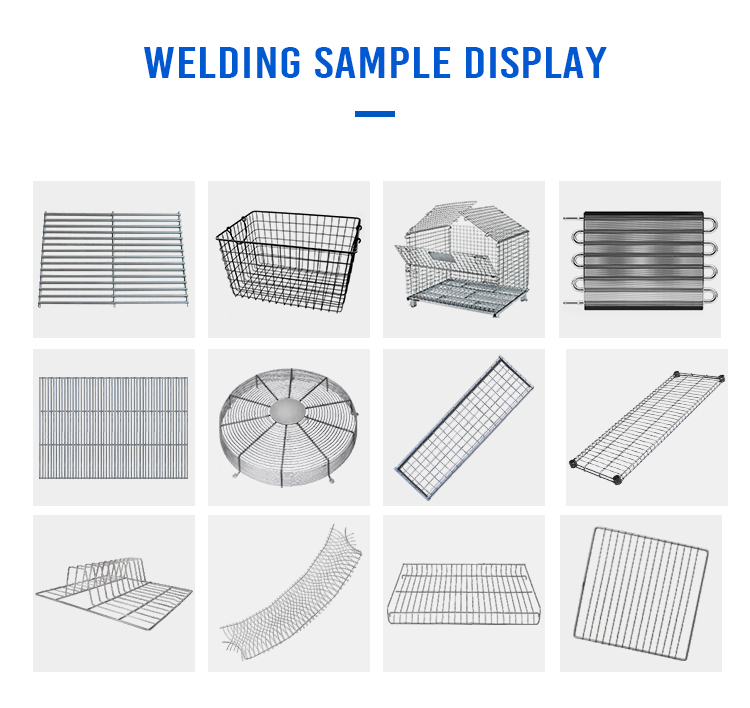

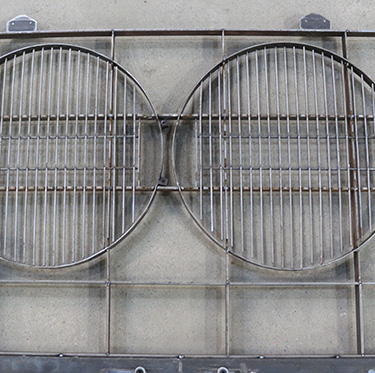

Wire welding machine adopts a single-head long arm type welding structure, equipped with work piece molds that move along the X and Y axis automatically. Input coordinated at a of welding position, welding current and other data to realize automatic welding. Just need to load the material manually and take out the work piece. lt is suitable for the welding of the mesh with in the range of 1000mm X 1000mm.

|  |

Intelligent welding control system Automatic welding by inputting coordinate data of welding position, welding current and other data. | Special product molds welding platform Processing and production according to the size of each mesh product |

|  |

X.Y axis moving device Equipped with automatic movement of the workpiece mold along X and Y axes, only manual swinging and removal of the workpiece is required | Single head long arm type welding The equipment adopts single head long arm type welding structure, can be customized according to the needs of the workpiece double row or multi-row welding head |

Specification

XY axis automatic moving wire welding machine

The XY axis mold frame is driven by servo motor with synchronous

belt drive, and the walking step length and speed are controlled by

the control system. When the manual material is fixed on the mold

frame, the switch is activated and controlled by the industrial

control computer, the product will walk alternately with the X and

Y axes of the mold frame to automatically complete the welding of

each part of the joints, and will automatically return to the

origin when the welding is completed, without the need for manual

operation by other personnel. At the same time, the operator can

set up the material to prepare for the next welding work, which not

only reduces the labor cost, but also effectively uses the welding

time to set up the material.