GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

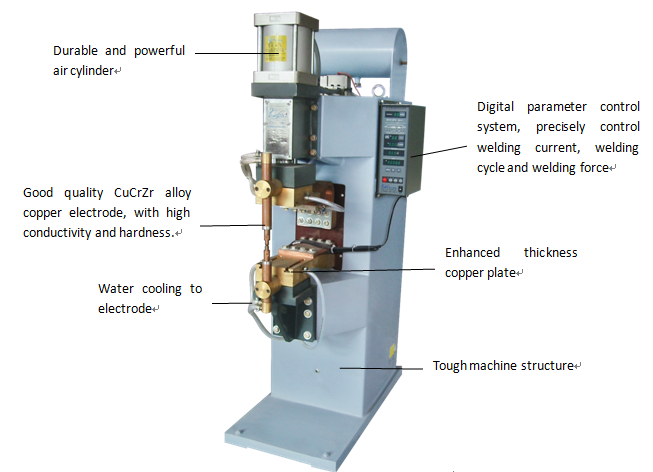

Air Press-Type Spot Welding Machine

SPECIFICATION

Model | Input | Input | Output Current | Pressurization | Electrode | Closure | Platform | Electrode | Cooling | |

V | KVA | A | kg | mm | mm | mm | mm | Lit/Min | ||

WL-SP-50K | 380/1 | 50 | 19500 | 500 | 80 | 145-225 | 250 | 320-420 | 6 | |

WL-SP-75K | 75 | 24000 | 1000 | 100 | 130-230 | 260 | 490-540 | 8 | ||

WL-SP-100K | 100 | 34000 | 1000 | 100 | 130-230 | 260 | 490-540 | 8 |

The Overall Dimension and Welding Capability

Model | Dimensions (mm) | Weight (kg) | Welding Capability (mm×Piece) | ||

Width | Depth | Height | |||

WL--50K | 480 | 900 | 1600 | 350 | 2+2 |

WL--75K | 780 | 1250 | 1800 | 400 | 2.5+2.5 |

WL--100K | 780 | 1250 | 1800 | 500 | 3+3 |

DESCRIPTION

Press-type welders operate in a straight-line motion. They can be

manually foot operated or air operated. Modern

press welders have air cylinders mounted directly over the ram

head, eliminating skidding of the electrode.

This vertical descent action is desirable for projection welding, as force can be applied evenly to all projections of a weld bolt or nut. The throat depth of a press welder is a fixed factor. If a larger than standard electrode clearance is required, either a retraction stroke or an adjustable stroke feature must be added.

Press welder advantages are:

1. No electrode skidding

2. Easily set up for projection welding

Disadvantages are:

1. Limited clearance over upper arm and ram head

2. Smaller electrode opening

3. Fixed throat depth

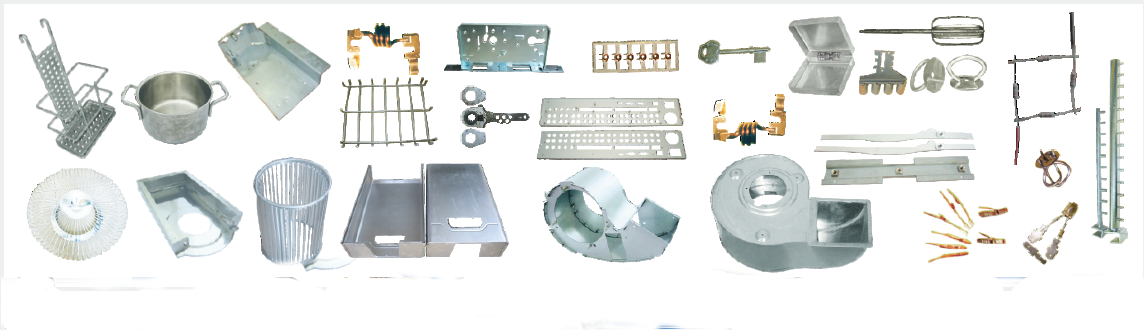

APPLICATION

1. Mild steel sheet, stainless steel sheet, galvanized metal sheet spot welding

2. Metal sheet fixing welding before continues rolling seam welding.

3. Welding fan guard (with proper designed fixing and driving system), welding metal artware, stationery, cook ware, and all kinds of daily metal products.

4. Welding high conductive material, like aluminum, electrical contact, copper wire etc.(using Middle frequency power)

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding

industry in China for 20 years; Factory direct

sale, competitive price.

2. Customized Service: We can help to design and develop

the welding machine according to your requirement. We are

flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months

warranty. Our machines are strictly complied with ISO9001:2000 and

China Compulsory Certification. Most of our machines enjoy 8-10

years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours

technical support by email. Our professional team is

always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time

delivery.

6. Prompt Response to Customers: Your satisfaction is the

goal we pursue.