GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

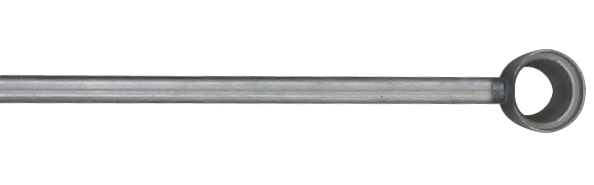

Connecting Rod , Link Stabilizer Welding Machine in Automobile Industry

DESCRIPTION

The shaft part will be clamped by cylinders while the bushing part will be located in the lower fixture. The lower fixture will be designed to match the bushing in order to ensure the effective conductivity of welding current. After starting the welding, the cylinder will clamp the shaft, then the lower fixture will rise up to welding.

FEATURE

1. Fixture: The adjustable fixture is designed with double guide rail device on both sides, matching with the precision-machined linear guide rail. The lower fixture is designed as cylinder rising up mode. Simple structure, convenient adjustment.

2. Power Source System: Adopt one set of 150KVA special resistance welding transformer as the welding power source. Continuous duty cycle rate is 50%; the output current is larger than 34000A. The executive standard is GB/15578-2008; the magnetic permeability of forced temperature control cooling water silicon steel sheet is larger than 13000GS; special cooling water subloop; It can ensure the output welding current of the whole machine is constant and powerful in order to obtain high quality, high efficiency, stable welding spots.

SPECIFICATION

No. | Item | WL-TP-150K |

1 | Input Power | Two-phase 380V±10% 50Hz (can be customized) |

2 | Rated Duty Cycle | 25% |

3 | Max. Secondary Floating Voltage | 6.75VAC |

4 | Max. Secondary Short Circuit Current | 34000A |

5 | Welding Transformer Insulation Grade | Grade F |

6 | Control Heat Adjusting Range | 15%~99% |

7 | Compensation for the Voltage Fluctuation of Power Grid | When the voltage flutuates within ±10% of the rated power grid value, the secondary voltage will fluctuate within ≤±5% |

8 | Clamping Cylinder | ¢80x50mm |

9 | Welding Cylinder | ¢100x80mm |

10 | Electrode Holder | ¢25mm |

11 | Welding Shaft Max. Length | 400mm (adjustable) |

12 | Rated Air Pressure | 0.6MPa |

13 | Gas Consumption | 10³/h |

14 | Water Pressure | 0.2Mpa |

15 | Water Temperature | 10-20℃ |

16 | Cooling Water Consumption | 100L/H(can be recycle) |

APPLICATION

Be able to applied to automobile industry, especially welding automoblie connecting rod.

MATERIAL CONFIGURATION

1. Adopt the energy storage type quick charge-discharge capacitor from Japan Nippon Chemi-Con (NCC) which is originated from MARGON or HITACHI; Fast discharge rate. Stable performance.

2. Adopt SEMIKON from West Germany, IXYS or IR Silicon controlled from United States. High precision and durable. Be able to achieve high stable control on the magnitude of current.

3. Adopt Motorola integrated circuits from United States. Quick response. Stable performance.

4. Adopt pneumatic parts from Japan or Taiwan with reliable performance.

5. All the devices are from imported famous brands with ideal service life and performance.

COMPETITIVE ADVANTAGE

1. Use ejector type holders for easy removal of tips

and to avoid damage to tip walls.

2. Prompt Response to Customers: Your satisfaction is the

goal we pursue

3. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

4. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

5. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

6. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

7. Quick Delivery: Our company provides just-in-time delivery.