GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

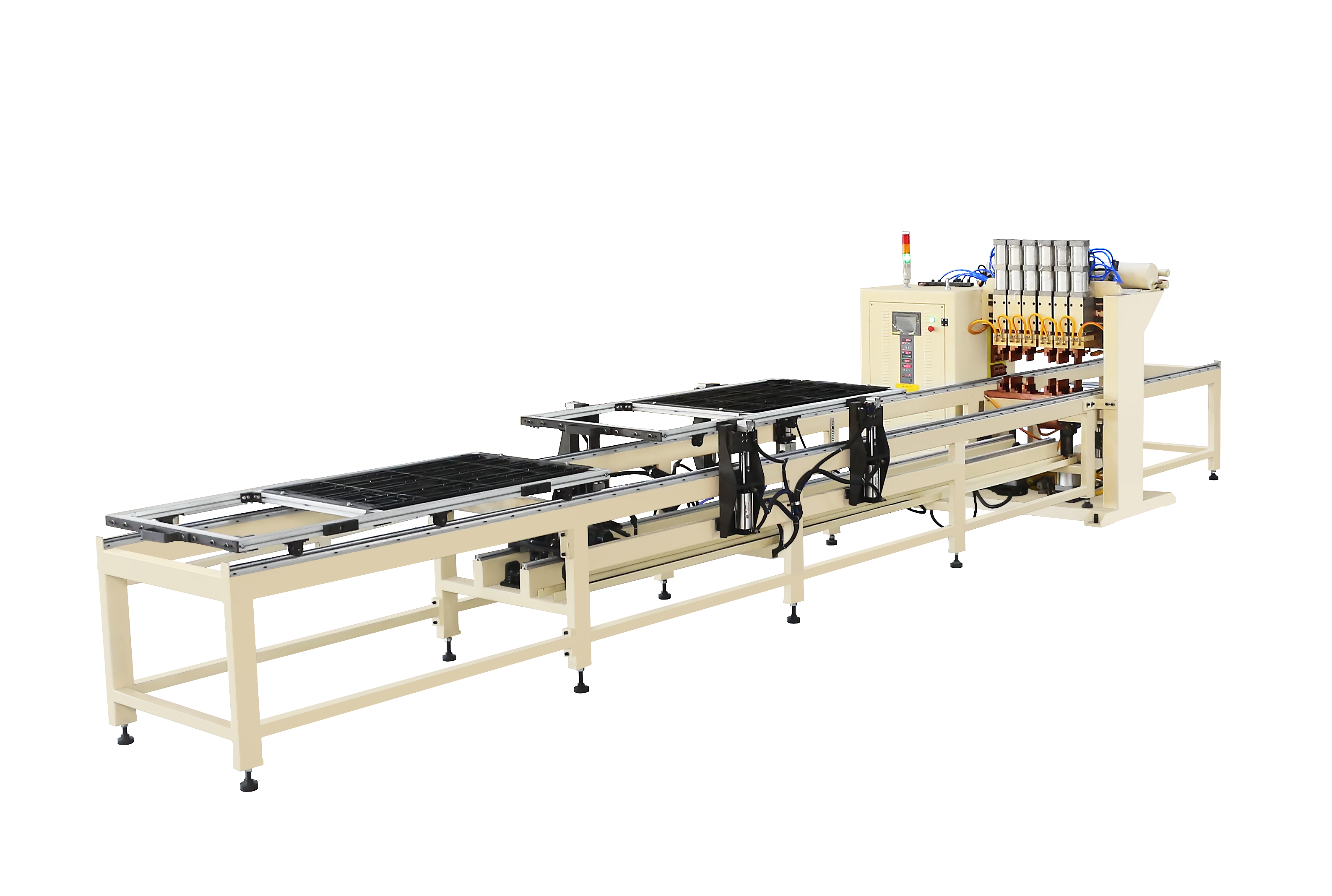

Detail machine picture please find bottom page.

DESCRIPTION

This machine can complete loading and fixing the work piece at one time. It can automatically move and weld as per preset location.Electrode can automaticlly enter into grinding system to repair and maintain the electrodes. It can be better to guarantee stable welding points. Improve product quality andproduction efficiency and reduce production cost. It solves the instable quality and low production efficiency defect of manual job. The maximum welding width is1200mm. welding length is no limitted.

FEATURE

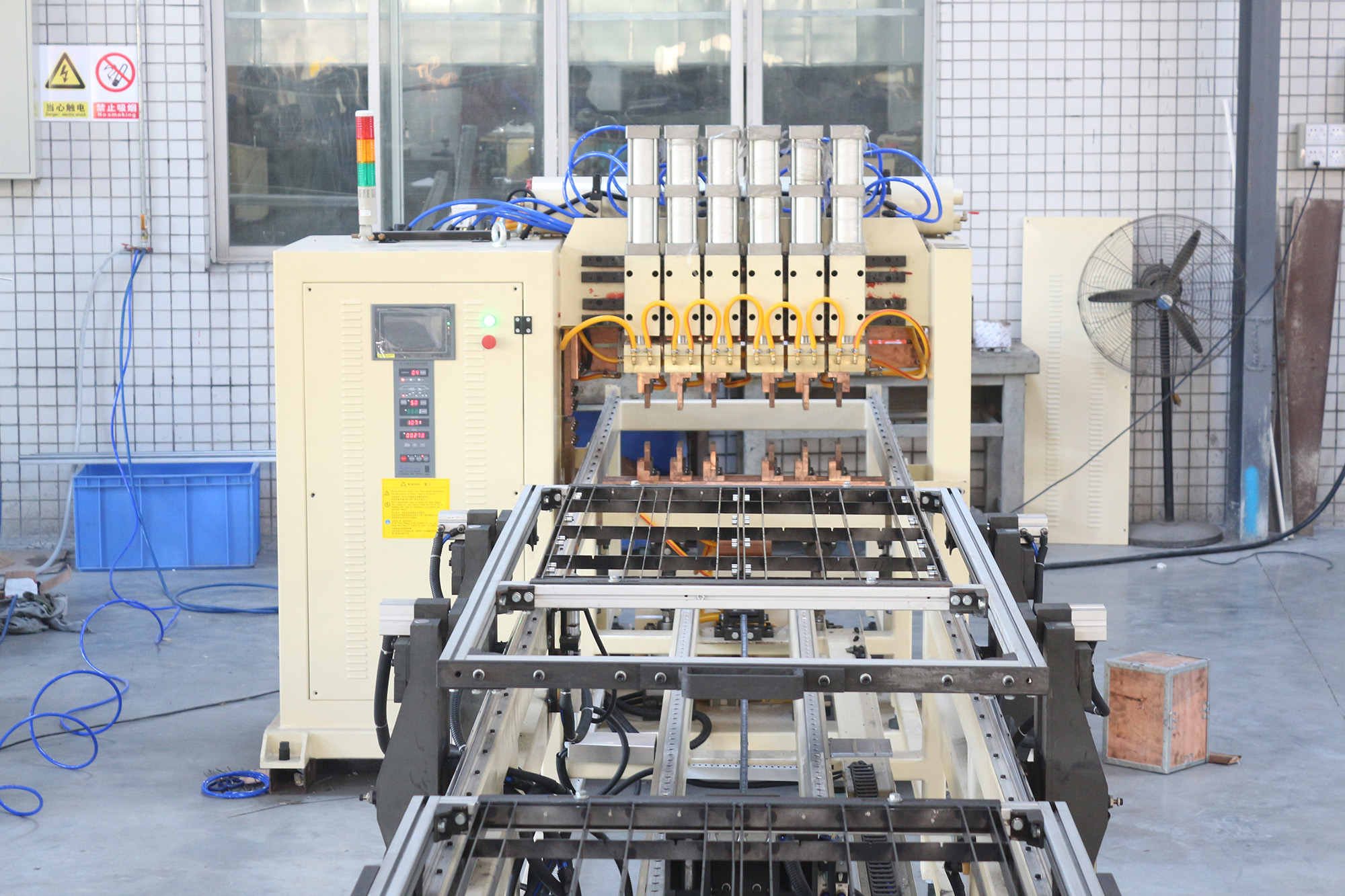

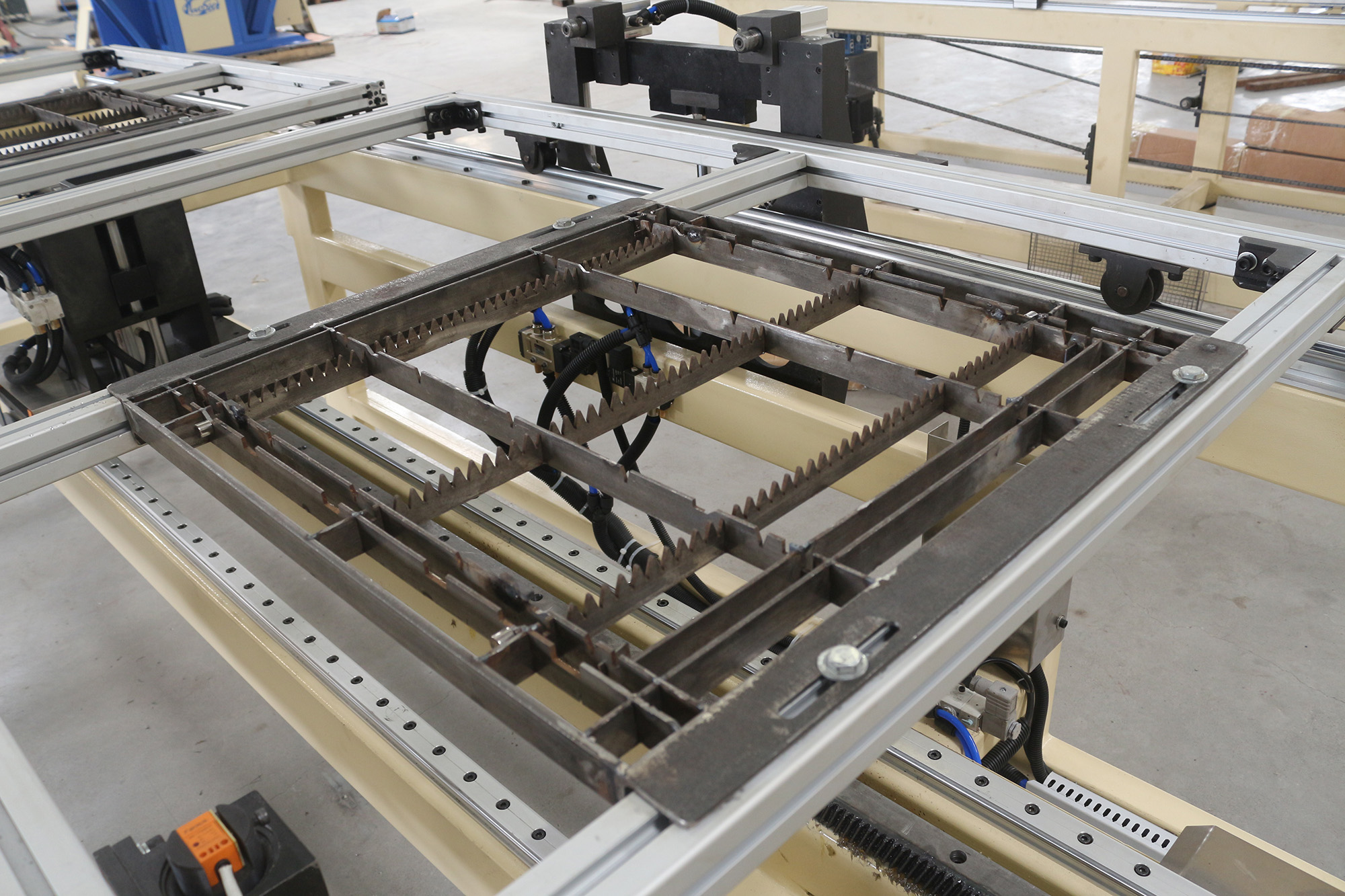

1.Welding heads are installed on the beam and equipped with slide rail so they can be moved from left to right. Convenient for adjusting the distance between the welding spots. Suitable for welding various kinds of product.

2.Upper electrode will conduct vertical movement during welding process. It can be adjusted from front to back. The lower electorde could be adjusted from left to right.

3.Except for manual wire filling. the feeding and welding is automatic. Labor force saving , high production rate.

| Model | WL-SQ-100K×6 |

| Input Voltage | Three/ two-phase 380V |

| Input Current | 400A |

| Output Voltage | 12V |

| Max Short Circuit Current | 45000A |

| Welding Effective Width | 1200mm |

| Welding Effective Length | 3000mm |

| Feeder Moving Speed | 500mm/sec |

| Upper Welding Cylinder | ¢100x100mm |

| Lower Welding Cylinder | ¢160x100mm |

APPLICATION

Suitable for multipoint wire mesh welding in material like low carbon steel. low steel alloy. stainless steel. galvanized steel. nickel plated steel.etx.

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.

Multiple head wire mesh automatic welding machine....