GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

10 heads Sheet Metal Welder for Plate , Sheet Metal Spot Welder

DESCRIPTION

1. Intellectual touch-screen microcomputer controller,completely digital control,automatic detection and compensation,loose welding and false welding are well prevented.

2. Panasonic touch-screen human-computer interface, Panasonic programer is adopted as the control hub, in charging of reading and dealing with control signal to guarantee that the machine operartion is in order and effective.

3. Groups of welding electrodes can be moved from left to right, all kinds of products are suitable to be welded. Welding electrodes can work in flexible order. No metal sheet deformation.

4. Pneumatic mechanism, the perssure of every electrodes can be adjusted, stable force is achieved. The upper electrodes have an adjustable working distance forwards and afterwards, the lower electrode mould installation is simple and flexible to be adjusted from left to right.

5. Encoding servo motor feeding rack mechanism, equipped with high precise slide guide and automatic detection device. Has the advantages of quick reaction, high precise control, powerful engine, and high effeciency.

FEATURE

1. Main body: It adopts reinforced steel body and good quality thick steel plate to ensure the strength and stability of the main body.

2. Welding Power Source: Choose the small power 100KW discharging transformer which is special used for resistance welding as the welding power source. To ensure the strength and stability of the welding,

3. Welding Control System: The secondary which is controlled by microcomputer will identify the output of current automatically in order to guarantee the constant current of each welding spot. In the meantime, the control system is equipped with the function of voltage compensation which is used for the automatic detection of the voltage change in order to ensure the constant strength of the welding spot.

SPECIFICATION

No. S.N | Item | Specification | Description |

1 | Input voltage | 380V ,2-phases | It can be customized, but only for 2-phases. |

2 | Input current

| 400A |

|

3 | Output voltage

| 12V |

|

4 | Max.Welding current

| 34000A |

|

5 | Effective welding width

| 1200mm (ajustable) |

|

6 | Effective welding length

| 3000mm (ajustable) |

|

7 | Feeding Rack Mobile speed

| 0.5m/sec | Servo motor transmitting |

8 | Upper welding air cylinder

| 100x100mm | Double force pressing cylinder |

9 | Lower cylinder | 160x100mm |

APPLICATION

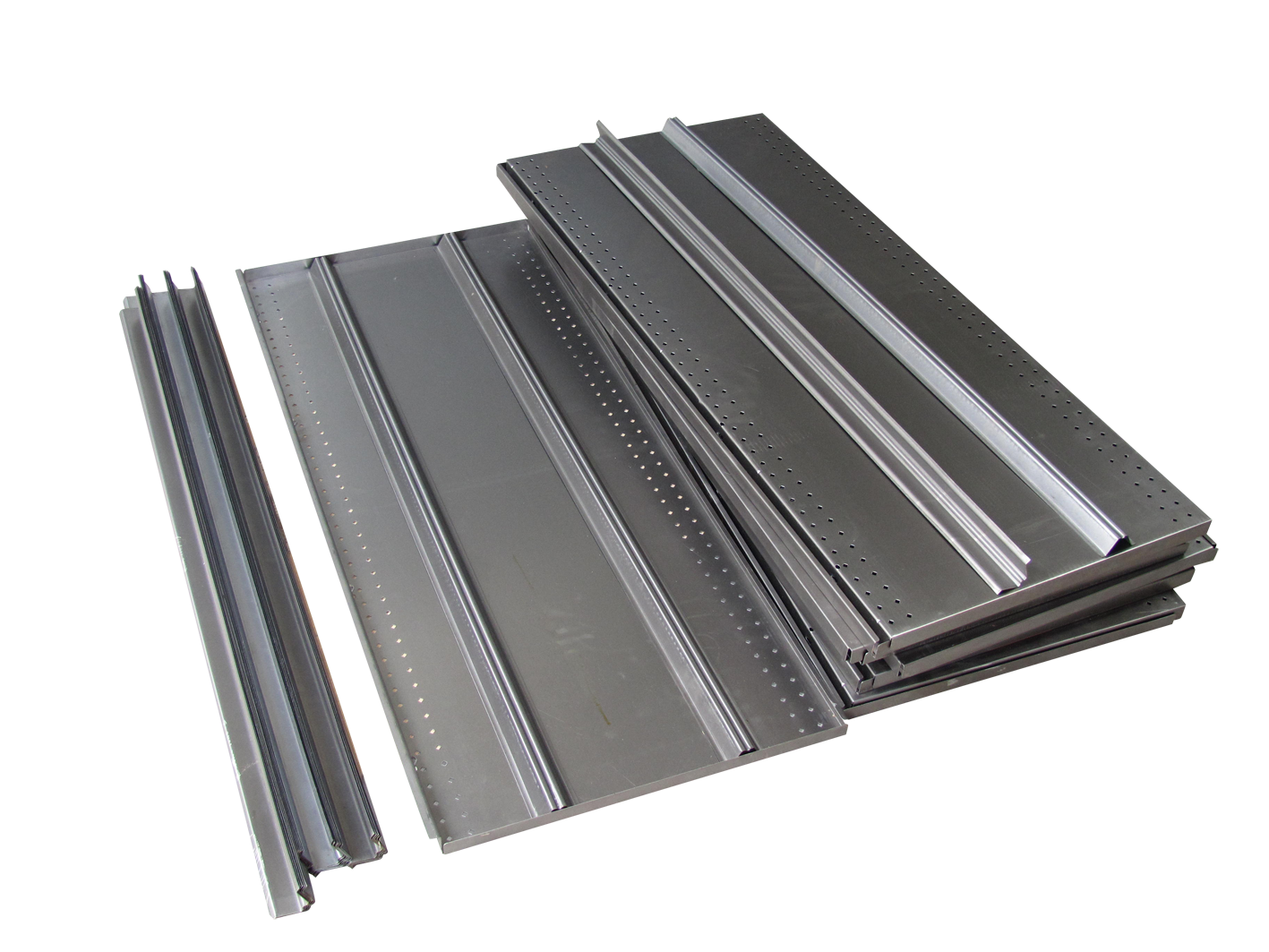

This machine is widely used to weld metal sheet in electronic appliances, automobile and other industries.

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.