GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

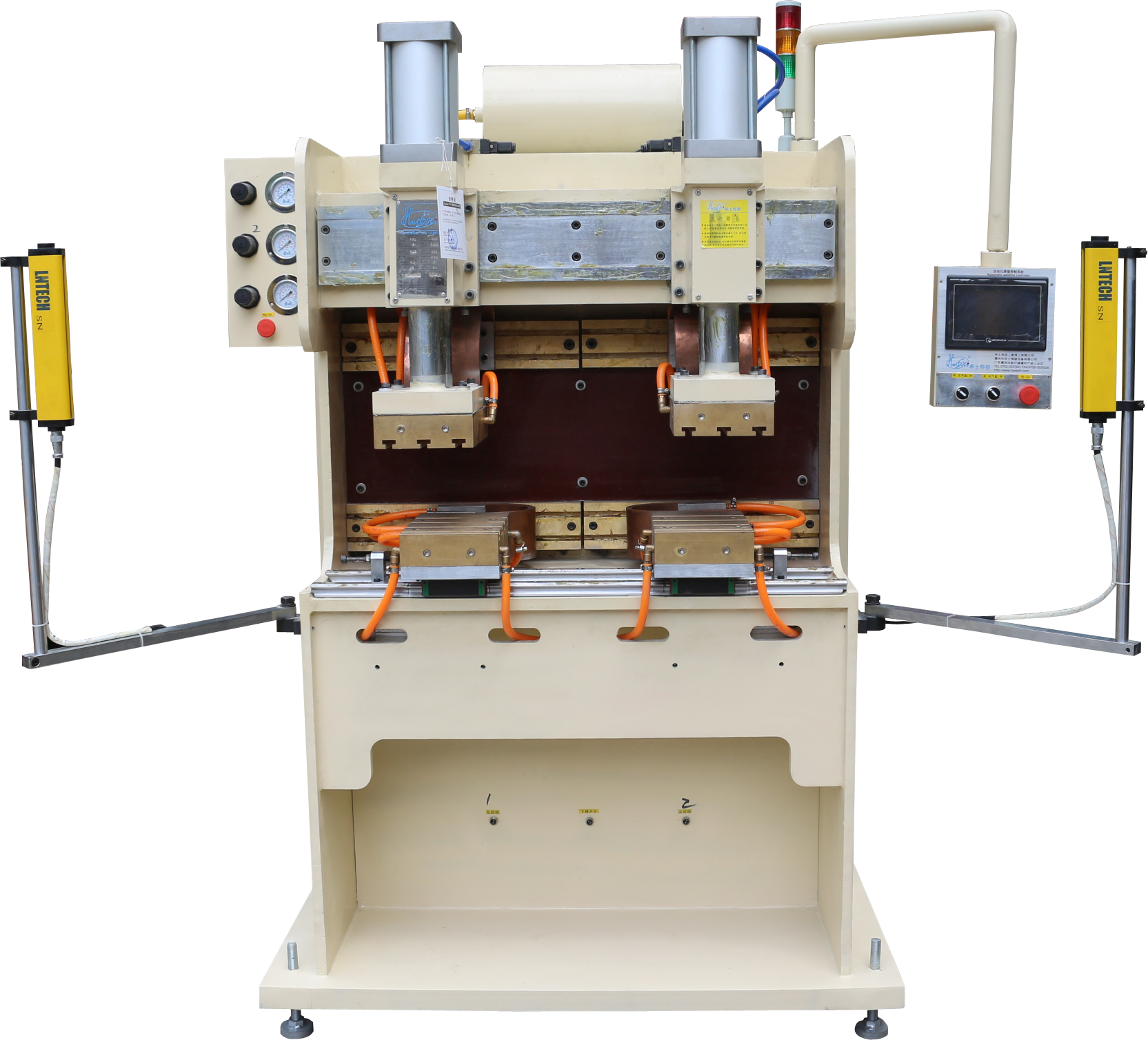

Electrical Welding Machine , Steel Printer Sheet Automatic Welder

DESCRIPTION

This machine is specially customized for welding printer shelf, printer box or printer sheet.Adopt 130 kva machine which is suitable for welding 3.5+3.5 mm thickness

This machine uses MF DC welding method. Adopt medium frequency welding power source, the welding spot will be good at looking and working efficiency is high.

The lower electrode is a flat locating mould which is designed according to your product

There are two sets of working tables with welding moulds for each side. According to the position of welding spots, the work piece will be moved on the CNC working table. When one of the working table enters into welding process, the other set is for the worker to prepare and load the material.

So while one working table is doing welding, you can load the printer box at the other working table, and take turn.

SPECIFICATION

No. | Item | Parameters |

1 | Input Voltage | 380V three-phase |

2 | Power | 130KVA |

3 | Welding Power Supply System | Medium frequency inverter |

4 | Putput Voltage | DC5.5V |

5 | Max Welding Current | 15000A |

6 | Max Storage Welding Models | 30 types |

7 | Max Welding Positions | 500 |

8 | Table Size | 200mmx300mm |

9 | X Axis Effective Distance | 300mm |

10 | Y Axis Effective Distance | 400mm |

11 | X Axis Moving Servo Motor | One set |

12 | Y Axis Moving Servo Motor | Two sets |

13 | Moving Speed | 800mm/sec |

14 | Servo Motor Power | 450W |

15 | Welding Cylinder | 2 pcs(60x50mm) |

16 | Upper Electrode | Two groups |

17 | Lower Electrode | Large Table Type |

APPLICATION

Suitable for welding office printer parts

MATERIAL CONFIGURATION

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.