GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

Automatic Wire Mesh Shelf Welding Machine , Koltuk Tel Ve Profil Kaynak Makine

DESCRIPTION

This machine is customized for welding Swing Base Wire Mesh with tube frame .

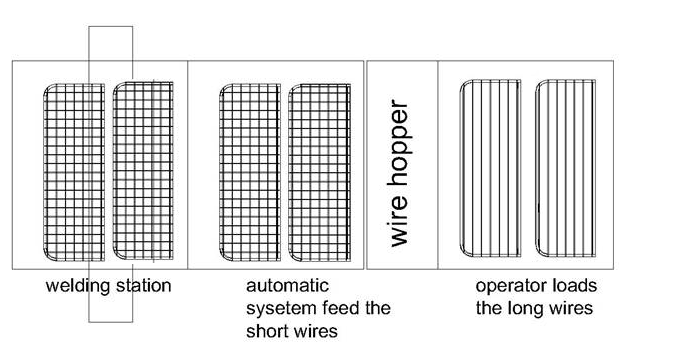

Adopts ten welding electrodes and automatic feeding system according to the following drawing of wire mesh. This machine can weld two pieces of such wire mesh each time. The operator only needs to put the wire and tube profile in the welding mould and press the start button, then the machine will conduct welding automatically. It is designed with double-layer feeding system. The welding position could be set at random. The feeder will move front and back for welding. It is suitable for batch production of wire mesh.

Process:

Power Source System: Adopts 2 sets of 100K MFDC transformer, The three-phase power supply, through rectified by a special inverter, is converted into 1000Hz AC voltage and then is transmitted to a medium frequency transformer. The current is rectified in order to supply DC welding current. This power source is different from the general type ac pulse power source because it can adjust rapidly and precisely. Small impact to the power grid and the requirement to the power grid capacity is much lower than the single-phase welder with the same capacity.

Welding Control System: Adopt the intelligent microcomputer quick response touch controller, all-digital control, simple and clear operational interface. Automatic testing and compensation which could guarantee the situation that the machine will be at work only when the current value is in the preset data so as to ensure the stability of welding effect and effective prevention of undesirable phenomena like loose welding and cold joint. It can Store 101 sets of special welding program. The features of quick response and high precision of control may help you obtain high quality of welding spots.

Automatic Wire Filling System: Automatic feeding the wire with 2mm diameter and the max length is 1000mm. Use the servo motor to drive and use cylinder to vibrate in order to make sure the wires are in ordered arrangement. This machine is designed 4 sets of automatic wire feeding system for the horizontal and vertical wire filling.

Technical Parameters:

| No. | Item | Parameter |

| 1 | Welding Power Source | MFDC 100K*2 |

| 2 | Input Voltage | Three phase 380V±10% 50Hz |

| 3 | Rated Capacity | 100KVA |

| 4 | Rated switch | 160KVA |

| 5 | Rated Duty Cycle | 50% |

| 6 | Frequency | 1000HZ |

| 7 | Control heat adjustment range | 15%~99% |

| 8 | Welding Model Storage | 101kinds |

| 9 | Output way | DC |

| 10 | Maximum Output Voltage | DC9.6V |

| 11 | Insulating Grade | F |

| 12 | The secondary maximum short-circuit current | 25KA |

| 13 | The degree of time adjusting range | 0~9999ms |

| 14 | Control System | Panasonic PLC |

| 15 | Welding head | Nine group |

| 16 | Effective Welding Width | 1400mm |

| 17 | Effective Welding Length | 1000mm |

| 18 | The feeder Servo Motor | 750W |

| 19 | Automatically Moved to speed | 500-1000mm/min (Adjustable) |

| 20 | Welding cylinder | Ø80x100mm( Double pressurized cylinder) |

| 21 | Lower Electrode Stroke | Ø160x50mm(Adjustable) |

| 22 | Wire filling institutions | 4 sets |

| 23 | The largest feed position | 1000mm |

| 24 | Servo motor power | 750W |

| 25 | Feeding speed | 200-500mm/min |

| 35 | Rated Air Pressure | 0.8MPa |

| 36 | The water pressure | 0.2Mpa |

| 37 | The cooling water consumption | 1000L/H |

| 38 | The water temperature | 10-20℃ |

| 39 | Water Chiller | 5P(Optional) |

| 40 | Equipment cover an area of | 10000x2400mm |

APPLICATION

Continuous welding wire mesh,Swing Base Wire Mesh and Tube Frame

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO 9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.

Automatic Wire Loading/ filling Hopper

Automatic Feeder with welding mould which can carry two pieces of swing base for welding

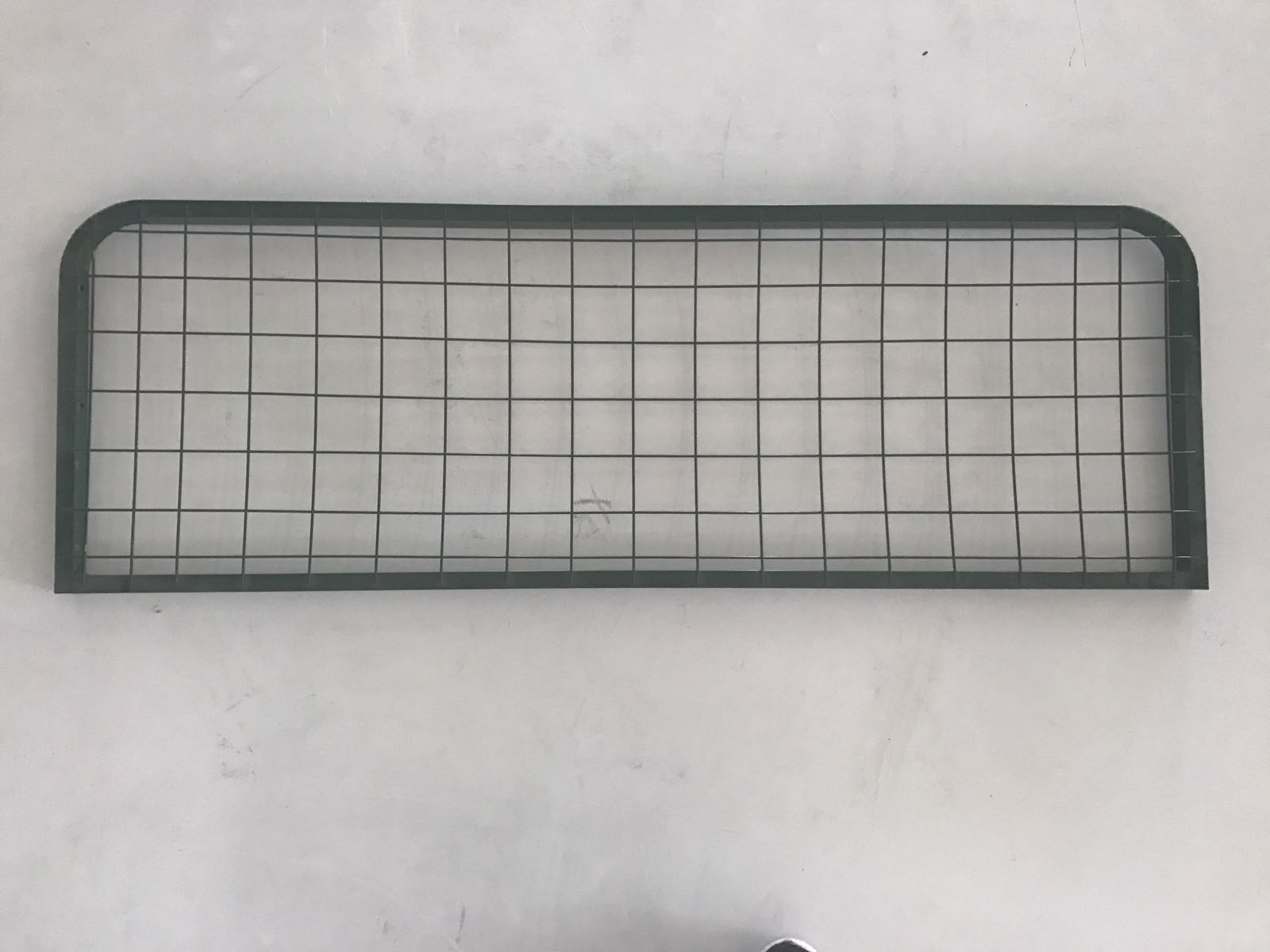

Samples for welding test

Ture Sample