GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

DESCRIPTION

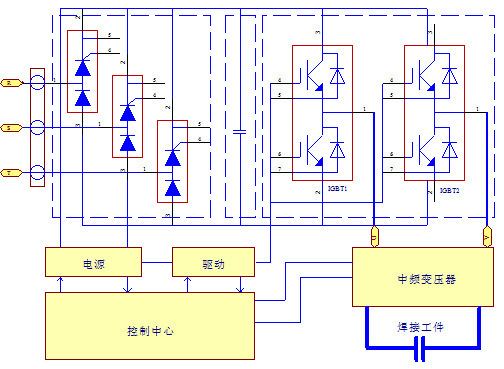

MF DC Inverter Spot Welder is a set of advanced welding equipment. The welding transformer is in small size but the outout energy is large. Three-phase AC will be converted into DC after being rectified. Then the DC will be converted into medium frequency 1000HZ square wave to be connected to primary welding transformer through the inverter circuit which is composed of IGBT. The MF square wave will become small pulse DC to the electrode for welding work piece through the depressurization and recitifying process in the welding transformer. The Inverter will adjust the duty ratio of IGBT through the feedback of secondary current so as to achieve constant current of the welding process.

Welding current

SPECIFICATION

Items | Specification |

Display | 5 Inches Blue Display Screen |

Rated Power | 10-400KVA |

Input Voltage | AC 380V, 50Hz |

Duty Cycle Rate | 25% |

Maximum Short Circuit Current | 25000A |

Inverter Frequency | 1000Hz |

Welding Cycle Period | 11 |

Welding Pulse Times | 3 |

Current Slow Rise And Down Control | Yes |

Stored Welding Models | 18 |

Throat Depth | 300mm( can be adjustable) |

Cylinder Size | ¢100x100mm( can be adjustable) |

Medium Frequency Welding Machine Welding Controller

Click here to download detail information about machine controller

Medium Frequency Inverter Welding Machine Controller-HWASHI.pdf

1.101 sets of programmable welding models,92 sets of seam welding modles. Be able to select the model directly when welding .

2.The function of welidng spot curretn increase progressively, efficiently solve the instability of welding effect caused by current shunt when doing multiple points welding.

3.Be able to set the preheat currrent ,welding current and tempering current, efficiently prevent the splash during the welding and work piece quenching after welding.The 3 electric pulses can be set separately and combine separately or freely.

4.Be able to slowly increase and decrease the current, effectively avoid the splash and defective nugget formation during welding,Be able to obtain excellent physical performance.

5.Energy saving,three phase power source output , high working frequency,low consumption of transformer,significant effect of saving energy.

6.Adopt DSP and PLD as main control unit. The electric cirsuit is simple, high intergrated, intelligent . Decrease the rate of malfunction. Easier maintenance.

APPLICATION

Widely applied to welding battery ,lighting electric resource automobile.medical apparatus and instruments,photoelectric communication, micro motor as well as requested chip inductor with high temperature enamed round wire/extra fine wire minimum size can be 0.02mm), wire rope,metal wire,nickle cup, can cutting wire and welding ,CCFL filed ,fuse,lamp filament.

FEATURE

1. The current in secondary weldin gloop is DC. Dramatically reduce the impact to the welding current due to the inductive reactance in secondary lopp when welding to the work piece.

2.Reduce power consumination, energy saving . Reduce the requirement of cables and lots of maintance cost.

3. Improve the power factor, reduce the production cost.

4. Reduce interference in secondary circuit which is in the large open area: the welding current is direct current. When there is induction or magnetic material in secondary winding, the welding will not be affected.

5. To make the power supply unit load balance: MF inverter projection welder adopts the three-phase sources which can store energy.

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.