GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

Inox Capacitor Discharge Projection Spot Welding Machine with Japan NCC Capacitor for Different Cookware

SPECIFICATION

Model | WL-C-25K |

Input Voltage | 380 V |

Input Power | 25KVA |

Energy Storage | 18000J |

Capacitance | 162000uF |

Pressurization | 2000kg |

Electrode Stroke | 100 mm |

Closure Measure | 130-230mm |

Platform Distance | 260mm |

Electrode Distance | 490-540mm |

Cooling Water | 15 Lit/min |

DESCRIPTION

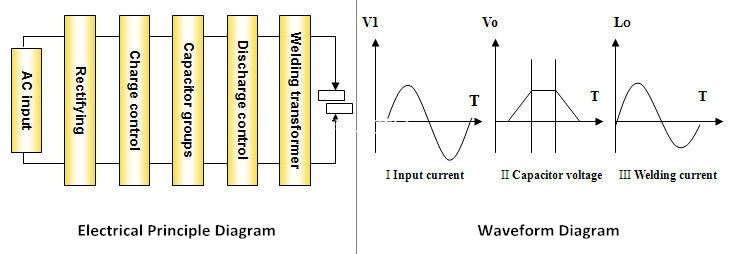

Stored energy welding machine is also called the capacitor stored energy welding machine, to use the capacitor stored energy is the main working principle, when energy can make a small area of solder melting and the instantaneous discharge, capacitance stored energy welding machine welding time is three over one thousand of a second, and the welding time is not adjust.

Capacitor discharge spot welder uses capacitor to store energy and to release instantaneous current. In the meantime, it concentrates large current to pass through a small point and then achieves welding effect (welding process passes through thousands of ampere current within 1/1000 second of time). Therefore, it can minimize the situation that the work piece being oxidized or mechanically deformed due to overheat during the process of welding. The output of the capacitor discharge spot welder that we produce is from 100WS to 18000WS. It is especially suitable for welding metals like red copper, bronze, brass, aluminum, silver and stainless steel, etc. Thus, this type of machine is widely applied to various kinds of industrial production and manufacturing.

Control Panel Diagram:

APPLICATION

The output of the capacitor discharge spot welder that we produce is from 100WS to 18000WS. It is especially suitable for welding metals like red copper, bronze, brass, silver and stainless steel, etc. Thus, this type of machine is widely applied to various kinds of industrial production and manufacturing.

MATERIAL CONFIGURATION

S.N. | Name | Specification | Brand | Orgin |

1 | PLC control system | PF series | Panasonic | Japan |

2 | Touch screen | GT series | Panasonic | Japan |

3 | Charging silicon controlled | KP-550 | MCC | U.S.A |

4 | Discharging silicon controlled | SKKT1000-12E | MCC | U.S.A |

5 | Rectifier diode | ZP-300A | MCC | U.S.A |

6 | Current-limiting resistance | 100W/100Ω | NANFA | Hongkong |

7 | Capacitance | 1000UF/475V | Nitponchemi.con | Japan |

8 | Discharging contactor | JMC-100 | LG | South Korea |

9 | Charging contactor | JMC-85 | LG | South Korea |

10 | Charging control panel | WD-20DC-1 | HWASHI | Home-made |

11 | Discharging control panel | WD-20DC-2 | HWASHI | Home-made |

12 | Charging switch | 50A-100A | MITSUBISHI | Japan |

13 | Tail switch | DS-231 | IDEC | Japan |

14 | The main magnetic valve | 6000# | SANWO | Korea |

15 | Pressing magnetic valve | 4# | SANWO | Korea |

16 | Air group | 6000# | SANWO | Korea |

17 | The main control cylinder | ¢160x100mm | ZHICHEN | Joint venture company |

***********************************************************************************************

We can design and manufacture the welding equipment according to your request/drawing, contact us please, we will offer you a suit solution and support you to success.

FEATURE

1. Wide Application: Be able to weld 8mm of nonferrous metals like stainless steel, aluminum, titanium, silver, etc. Overcome the difficulties in welding dissimilar metals like bronze, aluminum, etc.

2. Firm and Good Looking: Firm welding; No black coating on the welding spots so no polishing process is needed; especially suitable for welding those exporting products which have high requirement on good looking.

3. Electricity and Energy Saving: This machine gets low surge power from the power grid and the power factor is high. Compared with the common AC machine with the same capability, it uses only 1/7 to 1/10 of the power. With a low cost.

QUALITY STANDARD

1. Rated Value and Operation Condition of Electric Resistance Welding Equipment GB/T8366-2008

2. Safety Requirement of Electric Resistance Welding Equipment GB/15578-2008

3. Controller General Technical Specification of Electric Resistance Welding Equipment JB/T10110- 2008

4. Fixed Spot or Projection Welding Machine JB/T10101-2000

5.Transformer General Technical Specification of Electric Resistance Welding Equipment JB/T9529- 2008

6. QA Inspection Standard of Our Factory HS/040120006

COMPETITIVE ADVANTAGE

1. HWASHI is the leading brand in resistance welding industry in China for 20 years; Factory direct sale, competitive price.

2. Customized Service: We can help to design and develop the welding machine according to your requirement. We are flexible and capable Supplier.

3. Genuine Product with Excellent Quality: 12 months warranty. Our machines are strictly complied with ISO9001:2000 and China Compulsory Certification. Most of our machines enjoy 8-10 years service life. 100% guarantee test before delivery.

4. After Sales Service and Technical Assistance: 24 hours technical support by email. Our professional team is always here willing to be your technical consultant.

5. Quick Delivery: Our company provides just-in-time delivery.

6. Prompt Response to Customers: Your satisfaction is the goal we pursue.