GUANGDONG HWASHI TECHNOLOGY INC. |

|

Verified Suppliers

|

|

6 DOF CNC Industrial Automatic Arm Robot Welding Equipment with Robotic Arm

SPECIFICATION

| Name | HS-RAW06 | ||

| Type | Standard Type with integrated torch | ||

| Structure | 6-axis, independent multiple articulation | ||

| Wrist Load | 6kg | ||

| Motion Range | Max Reaching Distance | 1437mm | |

| Min Reaching Distance | 404mm | ||

| Front and Back Motion Range | 1033mm | ||

Motion Speed | Arm | Rotation | 225°/S |

| Lifting Arm | 225°/S | ||

| Stretching | 225°/S | ||

| Wrist | Rotation | 425°/S | |

| Bending | 425°/S | ||

| Reverse | 629°/S | ||

| Repeated Positioning Accuracy | Within ±0.08mm | ||

| Servo Motor | Total Power | 3400W | |

| Brake Specs | All shaft-driven brake | ||

| Installation | Normal | ||

| Weight | About 170kg | ||

DESCRIPTION

This automatic robot work station to achieve automatic work piece clamping and robot automatic welding process. It is designed with two sets of welding positioner. When one is under welding process, another one could be prepared for loading work piece.

APPLICATION

Applied to loading, unloading and welding industry.

FEATURES

1. Working station power supply control system: control power supply circuit, circuit-breaker protection. It is safe and reliable in use.

2. Welding system: Panasonic YD350-GR MIG welding machine with automatic wire feeding system. Stable performance.

3. Welding gun system: famous brand TBI welding gun.

4. Welding gun cleaning system: TBI brand.

5. Working station positioner: It is designed with two sets of working table. Single table could achieve 3600 rotation which is suitable for multi-angle welding. Two sets of positioner system could achieve 180°rotation through spindle motor. It could achieve alternative use so as to increase efficiency.

6. Work piece clamping system: the cylinders will push and clamp the work piece. Balanced and stable clamping force.

7. Arc light baffle: cylinder pushes automatic rotation. Use for preventing light pollution during working process.

8. Start control panel system: Manual/Automatic button platform with portable structure. Convenient for operation.

9. Safety protective fence system: for preventing people from getting close to the welding position and avoid accidents. Safety production.

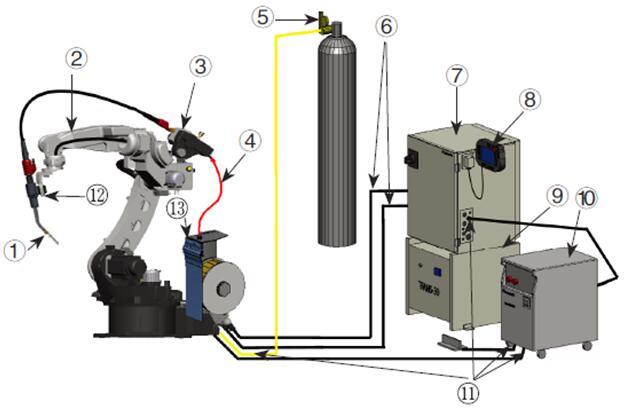

Machine CONNECTION

No. | Item |

1 | Welding Gun |

2 | Robot Arm |

3 | Wire feeder |

4 | Wire Filling Tube |

5 | Gas Flow meter |

6 | Robot Arm Connecting Cable |

7 | Robot Arm Controller |

| 8 | Demonstrator |

| 9 | Transformer |

| 10 | Welding Power Supply |

| 11 | Cable |

| 12 | Safty Support |

| 13 | Wire Reel |

***********************************************************************************************

We can design and manufacture the welding equipment according to your request/drawing, contact us please, we will offer you a suit solution and support you to success.

COMPETITIVE ADVANTAGE

1. Professional

Over 20 years of experience in wire mesh industry and export more than 50 countries. Hwashi is the real professional manufacture.

2. Product Quality

The quality of products is the key of enterprise survival. Hwashi is ISO9001:2000 certificated manufacture.

3. Reasonable Price

We’ll exact control each producing process to reduce cost for our customers.

After clients receive the quotation, we’ll show you the rationality of the price and the difference between our products and other supplier’s products.

4. Delivery Time

The customer’s need is delivery on time, rather an excuse.

We’ll make a production plan before producing, and the sales will regularly inform the production schedule and process to the customers.

5. Communication

English is the basic and other languages can be understood.

All customers’ e-mail will be replied within 2 hours at working hours and must be replied within 12 hours at non-working hours.

6. Customized

Personalized, professional service: we can provide different programs according to customers’ requirement, thus make customers choose the best and most appropriate one.

7. Technical Assistance

24 hours technical support by email. Our professional team is always here willing to be your technical consultant.